Advanced Filters

Category

Manufacturer

Condition

Lowered Mast Height

Raised Mast Height

Capacity

We Ship Anywhere in Canada and USA

This 2022 Raymond 752‑R45TT is a brand‑new, zero‑hour, factory freezer‑rated reach truck original...

Discover more2022 Raymond 752‑R45TT Single Reach – CSA Certified | 4,500 lb | 348” Triple Mast | 36V Electric | Factory Freezer Package | Battery Extra | Zero‑Hour | Brampton, ON

- Capacity

- 4500 LBS

- Load Center

- 24"

- Mast Spec

- 149/348

This 2021 Toyota 8FBE18U is a CSA/MOL‑certified 3‑wheel electric forklift ideal for tight warehou...

Discover more2021 Toyota 8FBE18U | 3,500 lb | 189" Mast | 48V Electric | Side Shift | CSA Certified | Brampton ON

- Capacity

- 3500

- Load Center

- 24"

- Raised Mast Height

- 189

This CSA/MOL‑certified 2015 Unicarriers FHD30‑A1 diesel forklift delivers 6,000 lb of lifting cap...

Discover more2015 Unicarriers FHD30‑A1 – CSA‑Certified Diesel Forklift | 6,000 lb Capacity | 187” Triple Mast | Side‑Shift | Brampton ON | Outdoor Yard & Export‑Ready Use

- Capacity

- 6000 lbs.

- Load Center

- 24"

- Raised Mast Height

- 187

This CSA‑certified 2016 Yale GLC080VX propane pneumatic‑tire forklift is engineered for indoor/ou...

Discover more2016 Yale GLC080VX – CSA Certified | LPG Pneumatic | 8,000 lb | 187” Triple Mast | Side Shift | Brampton ON

- Capacity

- 8000

- Load Center

- 24"

- Raised Mast Height

- 218

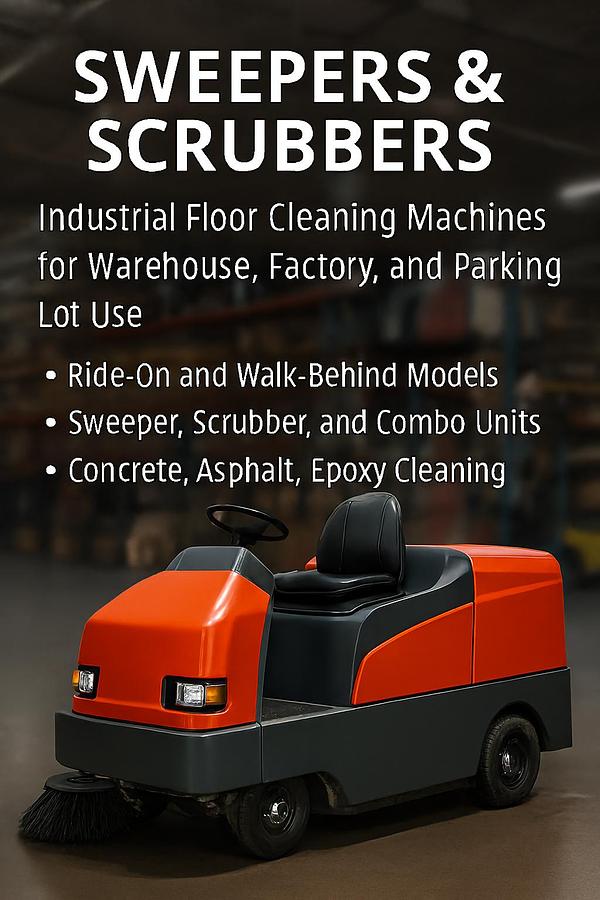

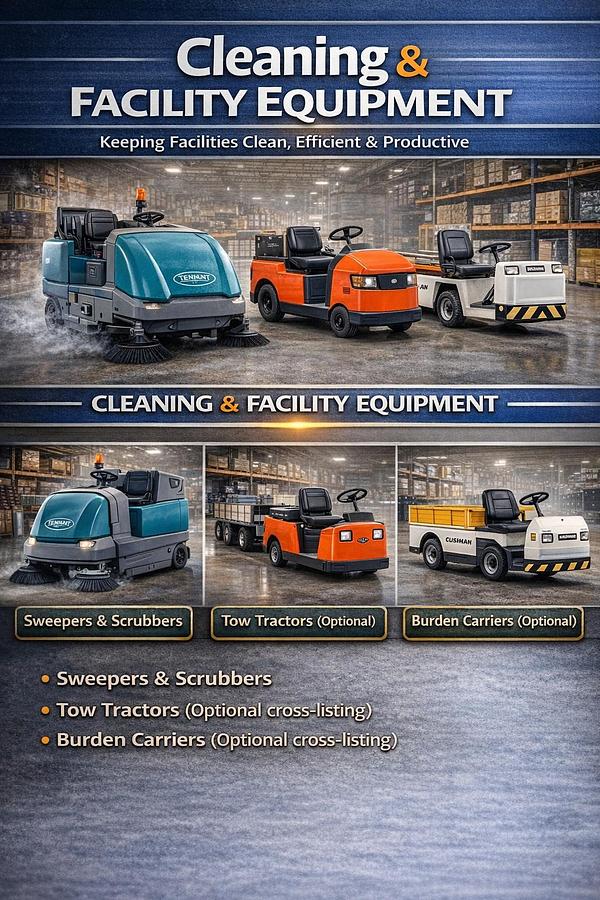

This 2023 Tennant S30 is a high‑capacity LPG‑powered industrial rider sweeper engineered for larg...

Discover more2023 Tennant S30 | LP Rider Sweeper | 137 Hours

- Power Type

- LPG

- Category Title

- (Ride‑On Scrubber / Walk‑Behind Scrubber / Sweeper / Sweeper‑Scrubber)

- Cleaning Path Width

- 80"

This 2020 Toyota 8FBCU20 is a premium 4‑wheel electric counterbalance forklift built for high‑dem...

Discover more2020 Toyota 8FBCU20 | 4,000 lb | 189" Triple Mast | 36V Electric | Side‑Shift | Premier Lift ID #5951642

- Capacity

- 4000

- Load Center

- 24"

- Fuel Type

- Electric

EE‑rated walkie straddle stackers are engineered for hazardous and controlled indoor environments...

Discover moreEE‑Rated Walkie Straddle Stackers | CSA‑Certified Hazard‑Zone Compact Lifting

- Category Overview

- This page represents our EE‑Rated Walkie Straddle Stacker category. Use it to compare models, understand hazardous‑location compliance, and match lift height, capacity, and aisle requirements to controlled‑environment applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is an EE‑rated walkie straddle stacker? An EE‑rated walkie straddle stacker is an electric lift truck designed for hazardous or controlled environments where enhanced electrical protection is required under UL and CSA standards. Where are EE‑rated stackers typically used? They are commonly used in chemical facilities, manufacturing plants, food processing, pharmaceutical environments, and any location requiring reduced ignition risk from electrical components. What makes a stacker “EE‑rated”? EE‑rated equipment includes enclosed motors, sealed electrical components, and additional safeguards to prevent sparks, arcs, or heat sources that could ignite flammable materials. What capacities and lift heights are available? Typical EE‑rated walkie straddle stackers range from 2,000–4,000 lb with lift heights from 120″–160″+, depending on mast configuration and model. Are these units suitable for narrow aisles? Yes. Walkie straddle stackers are designed for tight warehouse aisles, with compact chassis dimensions and precise operator control. Are these units CSA‑certified? Yes. All EE‑rated stackers supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Can EE‑rated stackers be used outdoors? They are intended for indoor use on smooth floors. Outdoor use is not recommended due to moisture, uneven surfaces, and environmental exposure. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major EE‑rated stacker brands.

- Classification

- Subcategory Page (Not an Equipment Listing)

This 2023 Toyota 8FBE20U is built on a 4,000 lb OEM chassis, delivering the stability, visibility...

Discover more2023 Toyota 8FBE20U | 4,000 lb | 258” Quad Mast | 48V Electric | Side‑Shift | Cushion Tires | Narrow‑Aisle 3‑Wheel

- Capacity

- 4000

- Load Center

- 24"

- Raised Mast Height

- 258

This 2019 Toyota 9BRU23 is a high‑performance reach truck built for dense warehouse environments ...

Discover more2019 Toyota 9BRU23 | 4,500 lb | 268” Lift | 112” Lowered | 36V Electric | Reach Truck | Narrow‑Aisle

- Capacity

- 4500

- Load Center

- 24"

- Raised Mast Height

- 268

Reach Trucks are engineered for high‑lift pallet storage, narrow‑aisle maneuvering, and deep‑lane...

Discover moreReach Trucks – High‑Lift Warehouse Solutions for Narrow‑Aisle Storage

- Category Overview

- Reach trucks are engineered for high‑lift pallet storage, narrow‑aisle maneuvering, and deep‑lane racking applications in modern warehouse environments. This category includes single‑reach trucks for standard racking and deep‑reach trucks for double‑deep storage, along with specialized reach‑type equipment designed for high‑density pallet handling and tall warehouse systems. These electric warehouse trucks deliver exceptional lift height, precise load control, and tight‑turn performance, making them ideal for distribution centers, 3PL operations, cold storage, and high‑throughput facilities. Typical capacities range from 3,000–5,500 lb with lift heights from 240” to 450”+, depending on mast configuration and application. All units are inspected for structural integrity, mast operation, steering, braking, and electrical performance, with optional CSA/MOL preparation available prior to delivery. This category is actively updated as new Toyota, Raymond, and Crown reach trucks enter our inventory, including 2020–2023 high‑lift, narrow‑aisle, and deep‑reach models.

- Frequently Asked Questions (FAQ)

- What types of reach trucks are included in this category? This category includes single‑reach and deep‑reach electric reach trucks designed for narrow‑aisle warehouse operations and high‑level pallet storage. Are reach trucks suitable for very narrow aisles? Yes. Reach trucks are engineered for tight turning and efficient pallet handling in narrow aisles, typically between 8–10 feet depending on model and load. What advantages do reach trucks offer over counterbalance forklifts? Reach trucks provide superior lift height, tighter maneuverability, and better visibility in racking environments. They are optimized for warehouse storage rather than dock or outdoor work. Are these units CSA‑certified? Yes. All reach trucks supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. What battery options are available? Units can be supplied with lead‑acid or lithium‑ion batteries. Lithium‑ion offers fast charging, zero maintenance, and strong multi‑shift performance. What lift heights and capacities are available? Typical reach trucks range from 3,000–5,500 lb with lift heights from 240″–450″+, depending on mast configuration. Can reach trucks be used on docks or outdoors? They are not ideal for docks or outdoor surfaces. Reach trucks are designed for smooth indoor warehouse floors and racking environments. Do you offer chargers and battery maintenance programs? Yes. Premier Lift Equipment provides new, used, and reconditioned chargers, along with battery maintenance, watering systems, and lithium‑ion upgrade programs.

- Supported Manufacturers

- Raymond · Crown · Toyota · Hyster · Yale · Cat · Mitsubishi · UniCarriers · Clark · Komatsu · Hyundai · Hangcha · Linde · STILL · Doosan · Jungheinrich

This electric double‑reach forklift — also known as a deep‑reach truck — is engineered for high‑d...

Discover moreElectric Double‑Reach Forklift – Deep‑Reach Pantograph for Narrow‑Aisle Warehouse Storage

- Category Overview

- Electric double‑reach forklifts are engineered for high‑density pallet storage, two‑deep racking, and narrow‑aisle warehouse environments. Using an extendable pantograph, these deep‑reach trucks place and retrieve pallets two positions deep while maintaining a compact chassis footprint, making them ideal for distribution centers, cold storage, 3PL operations, and high‑bay racking systems. This category includes 3,000–4,500 lb electric double‑reach trucks from leading OEMs such as Toyota, Raymond, Crown, and Hyster, with lift heights commonly ranging from 240” to 450”+. All units are inspected for structural integrity, mast operation, steering, braking, and electrical performance, with optional CSA/MOL preparation available prior to delivery. This category is actively updated as new Toyota, Raymond, and Crown deep‑reach trucks enter our inventory, including 2020–2023 high‑lift, freezer‑rated, and narrow‑aisle double‑reach models.

- Frequently Asked Questions (FAQ)

- What is a double‑reach narrow‑aisle forklift? A double‑reach truck uses an extendable pantograph to place and retrieve pallets two positions deep, increasing storage density in narrow‑aisle racking. What aisle widths do double‑reach trucks require? Most double‑reach units operate in aisles between 8–10 feet, depending on load size and model specifications. What advantages do double‑reach trucks offer over single‑reach models? Double‑reach trucks allow deeper pallet storage, reduce travel time, and increase warehouse capacity without expanding footprint. Are these units CSA‑certified? Yes. All double‑reach trucks supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. What battery options are available? Units can be supplied with lead‑acid or lithium‑ion batteries. Lithium‑ion offers fast charging, zero maintenance, and strong multi‑shift performance. What lift heights and capacities are available? Typical double‑reach trucks range from 3,000–4,500 lb with lift heights from 240″–450″+, depending on mast configuration. Can double‑reach trucks be used on docks or outdoors? No. They are designed strictly for smooth indoor warehouse floors and racking environments. Do you offer chargers and battery maintenance programs? Yes. Premier Lift Equipment provides new, used, and reconditioned chargers, along with battery maintenance, watering systems, and lithium‑ion upgrade programs.

- WHO THIS CATEGORY IS FOR

- This category serves operations requiring high‑density or double‑deep pallet storage, including: • Warehousing • 3PL and logistics • Cold storage • Food distribution • Retail fulfillment • Manufacturing • Packaging • Automotive

Single‑reach electric reach trucks are engineered for narrow‑aisle pallet storage, high‑density r...

Discover moreElectric Single‑Reach Forklift – Narrow‑Aisle Reach Truck (CSA‑Certified)

- Category Overview

- Single‑reach forklifts are designed for high‑density warehouse environments where operators need maximum lift height, precise load handling, and exceptional maneuverability in narrow aisles. These electric reach trucks use an extending carriage to place pallets deep into racking while maintaining a compact chassis footprint, making them ideal for distribution centers, manufacturing facilities, and high‑turnover storage operations. This category includes 3,500–4,500 lb electric reach trucks from leading OEMs such as Toyota, Raymond, and Crown, with lift heights commonly ranging from 240” to 360”. All units are inspected for structural integrity, mast operation, steering, braking, and electrical performance, with optional CSA/MOL preparation available prior to delivery. This category is actively updated as new Toyota, Raymond, and Crown single‑reach trucks enter our inventory, including 2020–2023 high‑lift and narrow‑aisle models.

- Frequently Asked Questions (FAQ)

- What is a single‑reach narrow‑aisle forklift? A single‑reach truck uses an extendable pantograph to place and retrieve pallets one position deep, optimized for narrow‑aisle warehouse storage. What aisle widths do single‑reach trucks require? Most single‑reach units operate in aisles between 8–10 feet, depending on load size and model specifications. How does a single‑reach truck differ from a double‑reach truck? Single‑reach trucks handle one pallet position deep, offering faster cycle times and simpler operation compared to double‑reach units. Are these units CSA‑certified? Yes. All single‑reach trucks supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. What battery options are available? Units can be supplied with lead‑acid or lithium‑ion batteries. Lithium‑ion offers fast charging, zero maintenance, and strong multi‑shift performance. What lift heights and capacities are available? Typical single‑reach trucks range from 3,000–5,500 lb with lift heights from 240″–450″+, depending on mast configuration. Can single‑reach trucks be used on docks or outdoors? They are designed for smooth indoor warehouse floors and are not ideal for dock plates or outdoor surfaces. Do you offer chargers and battery maintenance programs? Yes. Premier Lift Equipment provides new, used, and reconditioned chargers, along with battery maintenance, watering systems, and lithium‑ion upgrade programs.

- Supported Manufacturers

- Raymond · Toyota · Crown · Yale · Hyster · Cat · Mitsubishi · UniCarriers · Clark · Komatsu · Hyundai · Hangcha · Jungheinrich · Linde · STILL · Doosan

3‑wheel electric sit‑down forklifts are engineered for tight‑aisle maneuverability, high‑density ...

Discover more3‑Wheel Electric Sit‑Down Forklifts – Tight‑Aisle Indoor Material Handlers (CSA‑Certified)

- Category Overview

- This page represents our 3‑Wheel Electric Stand‑Up Counterbalance category. Use it to compare models, understand available configurations, and match capacity, mast height, and aisle performance to your application. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of 3‑wheel electric stand‑up forklifts are included in this category? This category includes 3‑wheel stand‑up electric counterbalance forklifts designed for tight‑aisle maneuverability, fast directional changes, and efficient indoor material handling. Are 3‑wheel stand‑up forklifts suitable for narrow aisles? Yes. Their compact chassis and tight turning radius make them ideal for narrow‑aisle warehouse environments where space efficiency is critical. What advantages do stand‑up electric forklifts offer over sit‑down models? Stand‑up units provide superior visibility, faster on/off access, and better maneuverability in confined spaces. They are preferred for high‑frequency, short‑travel warehouse operations. Are these forklifts CSA‑certified? Yes. All units supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. What battery options are available? Units can be supplied with lead‑acid or lithium‑ion batteries. Lithium‑ion offers fast charging, zero maintenance, and strong multi‑shift performance. What capacities and lift heights are available? Typical 3‑wheel stand‑up forklifts range from 3,000–4,000 lb with mast heights from 189″–240″+, depending on model and configuration. Are these suitable for dock work? They can handle light dock work, but sit‑down counterbalance forklifts are generally better suited for heavy dock loading and outdoor transitions. Do you offer chargers and battery maintenance programs? Yes. Premier Lift Equipment provides new, used, and reconditioned chargers, along with battery maintenance, watering systems, and lithium‑ion upgrade programs.

- Equipment Types Included

- 3‑Wheel Sit‑Down Forklifts • Tight‑Aisle Electric Forklifts • Freezer‑Rated Electric Forklifts • High‑Lift Indoor Forklifts • Multi‑Shift Electric Forklifts

This 2020 Toyota 8FBE20U is built on a 4,000 lb OEM chassis, offering excellent maneuverability, ...

Discover more2020 Toyota 8FBE20U | 4,000 lb | 189” Triple Mast | 36V Electric | Side‑Shift | Cushion Tires | Narrow‑Aisle 3‑Wheel

- Capacity

- 4000

- Load Center

- 24"

- Raised Mast Height

- 189

Electric walkie straddle stackers are engineered for closed‑bottom pallet handling, vertical lift...

Discover moreElectric Walkie Straddle Stackers – CSA‑Certified Closed‑Bottom Pallet Handling & Vertical Lifting

- Category Overview

- This page represents our 4‑Wheel Electric Forklift category. Use it to compare models, understand lift‑height requirements, and match capacities, mast types, and battery voltages to indoor warehouse and light outdoor applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a 4‑wheel electric forklift? A 4‑wheel electric forklift is a counterbalance truck powered by an electric battery, offering stable handling, smooth operation, and zero emissions for indoor and mixed‑use environments. Where are 4‑wheel electric forklifts typically used? They are commonly used in warehouses, distribution centers, manufacturing plants, food facilities, and operations requiring clean, quiet, and efficient material handling. What lift heights and capacities are available? Typical 4‑wheel electric forklifts range from 3,000–12,000 lb with lift heights from 189″–276″+, depending on mast configuration and model. What battery voltages are available? Most units operate on 36V, 48V, or 80V systems, with higher voltages offering stronger performance and longer runtime. Are electric forklifts suitable for outdoor use? Yes, many models can operate outdoors on smooth surfaces, though they are primarily optimized for indoor environments. Are these units CSA‑certified? Yes. All 4‑wheel electric forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Do electric forklifts require less maintenance than IC forklifts? Yes. Electric forklifts have fewer moving parts, no engine oil, and reduced wear, resulting in lower maintenance requirements. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major electric forklift brands.

- Supported Manufacturers

- Raymond / Crown / Toyota / Hyster / Yale / Cat / Mitsubishi / UniCarriers / Clark / Hangcha / Linde / Hyundai / Doosan / Big Joe / Noblelift

Pneumatic tire 4‑wheel sit‑down forklifts are engineered for outdoor industrial environments wher...

Discover morePneumatic Tire 4‑Wheel Sit‑Down Forklifts – Outdoor IC | 3,000–15,500 lb | CSA‑Certified Yard Forklifts

- Category Overview

- This page represents our Propane Cushion‑Tire IC Forklift category. Use it to compare models, understand lift capacities, and match mast height, turning radius, and tire type to indoor warehouse applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a propane cushion‑tire IC forklift? A propane cushion‑tire IC forklift is a sit‑down counterbalance unit powered by LPG, designed for smooth indoor warehouse floors and tight maneuvering. What applications are these forklifts best suited for? They are ideal for indoor warehousing, manufacturing, distribution centers, and dock operations where strong lifting performance and quick travel speeds are required. What capacities and mast heights are available? Typical units range from 3,000–6,000 lb with mast heights from 189″–240″+, depending on model and configuration. Why choose cushion tires for indoor IC forklifts? Cushion tires provide a smaller turning radius and excellent maneuverability on smooth concrete floors, making them ideal for tight warehouse layouts. Are these forklifts CSA‑certified? Yes. All propane cushion‑tire IC forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Can these forklifts be used outdoors? They can operate on smooth pavement, but cushion tires are not suitable for gravel, uneven surfaces, or rough terrain. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major IC forklift brands.

- Supported Manufacturers

- Toyota, Hyster, Yale, Crown, Komatsu, Nissan/UniCarriers, Clark, Linde

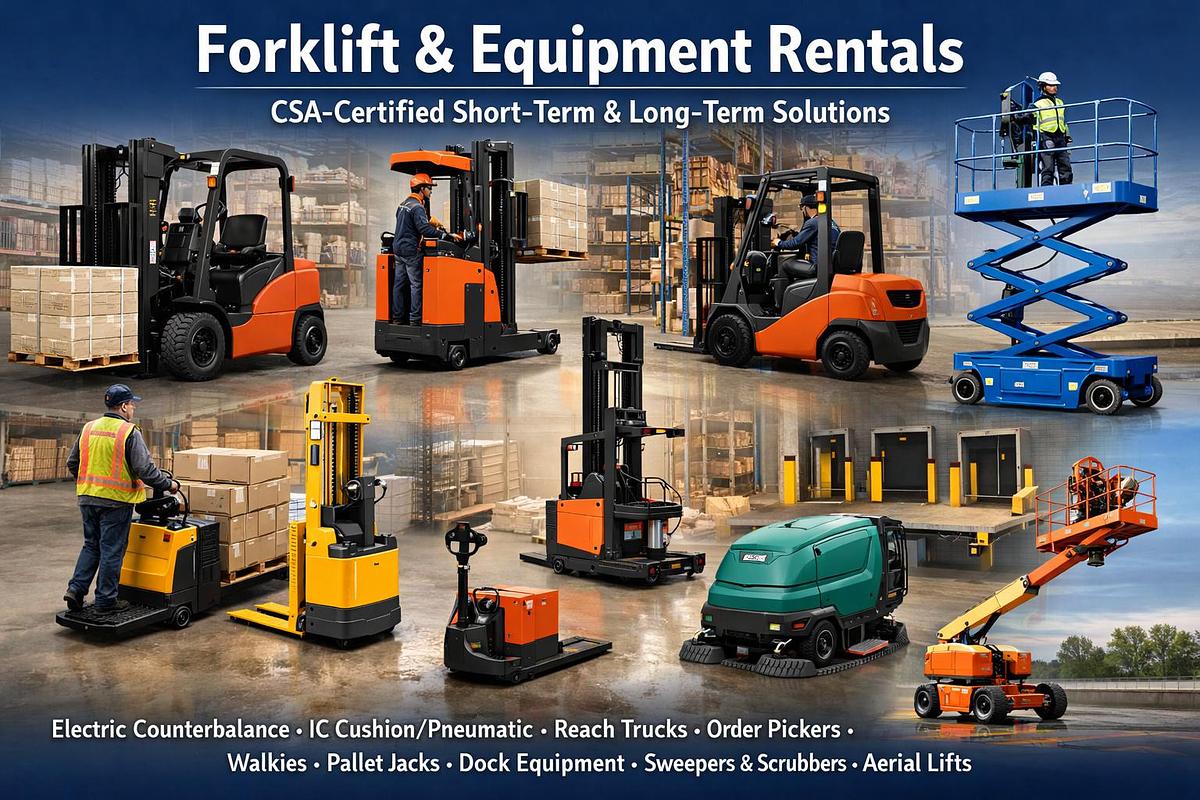

Propane Forklift Rentals provide high‑performance indoor and outdoor material‑handling solutions ...

Discover moreForklift & Equipment Rentals | CSA‑Certified Short‑Term & Long‑Term Solutions

- Category Overview

- This page represents our Forklift & Equipment Rentals master category. Use it to compare rental programs, equipment classes, and CSA‑aligned solutions for warehouses, 3PL operations, manufacturing, food distribution, cold storage, and industrial facilities. Rental terms include daily, weekly, monthly, seasonal, peak‑period, and emergency replacement programs. All units are fully serviced, CSA/MOL aligned, and configured for safe, reliable operation. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- Do you offer daily, weekly, and monthly rental programs? Yes — propane forklift rentals are available daily, weekly, monthly, seasonal, and for emergency replacement needs. Are propane forklifts CSA/MOL compliant? Yes — every rental unit is aligned with CSA B335 and MOL safety expectations, including pre‑shift inspection support and bilingual safety signage. Do you deliver and pick up rental forklifts? Yes — delivery and pickup are available across the GTA and surrounding regions. What types of propane forklifts are available? Indoor IC cushion forklifts for smooth warehouse floors, outdoor IC pneumatic forklifts for yards and rough surfaces, and high‑capacity propane units for industrial applications. Can I rent multiple forklifts for a project or facility? Yes — multi‑unit, multi‑facility, and seasonal fleet‑deployment programs are available. Do you offer rental‑to‑own options? Yes — rental‑to‑own programs are available (OAC) for customers who want to convert a rental into a long‑term asset. What industries use propane forklift rentals? Warehousing, 3PL, manufacturing, construction supply, lumber and building materials, automotive, and industrial distribution. Are propane forklifts suitable for indoor use? IC cushion forklifts are suitable for indoor smooth‑floor environments with proper ventilation and adherence to facility safety protocols. Are propane forklifts suitable for outdoor use? IC pneumatic forklifts are designed for outdoor yards, construction supply, uneven surfaces, and mixed‑terrain environments.

- Classification

- Rental Subcategory Page (Not an Equipment Listing)

This 2016 Toyota 8FBE15U is a compact 3‑wheel electric counterbalance ideal for tight warehouse a...

Discover more2016 Toyota 8FBE15U – 3,000 lb – 189" FSV Mast – 36V Electric – Side‑Shift Fork Positioner

- Capacity

- 3000

- Load Center

- 24"

- Raised Mast Height

- 189

This refurbished 2014 Raymond RSS walkie straddle stacker delivers dependable narrow‑aisle pallet...

Discover more2014 Raymond RSS | 4,000 lb | 128" Lift | 24V Electric | Refurbished & CSA‑Ready | Brampton ON

- Capacity

- 4000

- Load Center

- 24"

- Fuel Type

- Electric

This refurbished 2019 Raymond RSS walkie straddle stacker delivers reliable narrow‑aisle pallet s...

Discover more2019 Raymond RSS | 4,000 lb | 128" Lift | 24V Electric | Refurbished & CSA‑Ready | Brampton, ON

- Capacity

- 4000

- Load Center

- 24

- Fuel Type

- Electric

Outdoor diesel forklifts are engineered for heavy‑duty industrial environments where maximum torq...

Discover moreOutdoor Diesel Forklifts – Pneumatic Tire IC (3,000–36,000 lb | CSA‑Certified)

- Category Overview

- This page represents our Compact Indoor Cushion‑Tire IC Forklift category. Use it to compare models, understand lift capacities, and match mast height and turning radius to tight indoor warehouse applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a compact cushion‑tire IC forklift? A compact cushion‑tire IC forklift is a propane‑powered sit‑down counterbalance unit designed for tight indoor warehouse aisles and smooth concrete floors. What applications are these forklifts best suited for? They are ideal for indoor warehousing, manufacturing, distribution centers, and dock work where maneuverability and strong lifting performance are required. What capacities and mast heights are available? Typical units range from 3,000–6,000 lb with mast heights from 189″–240″+, depending on model and configuration. Why choose cushion tires for indoor IC forklifts? Cushion tires provide a smaller turning radius and excellent maneuverability on smooth indoor floors, making them ideal for tight warehouse layouts. Are these forklifts CSA‑certified? Yes. All compact IC forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Can these forklifts be used outdoors? They can operate on smooth pavement, but cushion tires are not suitable for gravel, uneven surfaces, or rough terrain. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major IC forklift brands.

- Mast heights

- 80"–300"

Electric counterbalance forklifts are the industry standard for indoor material handling, dock wo...

Discover moreElectric Counterbalance Forklifts – Indoor & Outdoor Electric Lift Trucks

- Category Overview

- This page represents our Electric Counterbalance Forklift category. Use it to compare models, understand available configurations, and match capacity, mast height, and tire type to your application. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of electric counterbalance forklifts are included in this category? This category includes 3‑wheel electric, 4‑wheel electric, cushion tire electric, pneumatic tire electric, lithium‑ion electric, and high‑capacity electric forklifts for indoor and indoor/outdoor applications. Are electric counterbalance forklifts suitable for outdoor use? Yes — pneumatic tire electric and lithium‑ion electric models can operate outdoors on smooth or moderately uneven surfaces. Cushion tire electric units are best suited for indoor environments. What advantages do electric counterbalance forklifts offer over propane or diesel? Electric units provide zero emissions, lower operating costs, reduced noise, improved operator comfort, and strong low‑speed torque. They are ideal for clean‑environment, food‑grade, and multi‑shift operations. Are these forklifts CSA‑certified? Yes — all electric counterbalance forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. What battery options are available? Units can be supplied with lead‑acid, AGM, or lithium‑ion batteries. Lithium‑ion provides fast charging, zero maintenance, and multi‑shift performance. What capacities and lift heights are available? Typical electric counterbalance forklifts range from 3,000–12,000 lb with mast heights from 189″–300″+, depending on model and configuration. Are electric forklifts suitable for cold storage? Yes — cold‑storage‑rated electric forklifts with heated controllers, sealed electronics, and low‑temperature hydraulic fluids are available. Do you offer chargers and battery maintenance programs?

- Supported Manufacturers

- Toyota · Raymond · Crown · Hyster · Yale · Cat · Mitsubishi · UniCarriers · Clark · Komatsu · Hyundai · Hangcha · BYD · Linde · STILL · Doosan · Jungheinrich

4‑wheel electric counterbalance forklifts are engineered for stable indoor lifting, high‑capacity...

Discover more4‑Wheel Electric Forklifts – Stable Indoor Counterbalance (CSA‑Certified | 3,000–12,000 lb)

- Category Overview

- This page represents our 4‑Wheel Electric Counterbalance Forklift category (3,000–12,000 lb). Use it to compare models, understand available configurations, and match capacity and mast height to your application. For technical guidance, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of 4‑wheel electric counterbalance forklifts are included in this category? This category includes indoor and indoor/outdoor 4‑wheel electric forklifts ranging from 3,000–12,000 lb, with cushion or pneumatic tires depending on the application. Are 4‑wheel electric forklifts suitable for outdoor use? Yes — pneumatic tire electric models can operate outdoors on smooth or moderately uneven surfaces. Cushion tire units are best suited for indoor warehouse and manufacturing environments. What advantages do 4‑wheel electric forklifts offer over propane or diesel? Electric units provide zero emissions, lower operating costs, reduced noise, improved operator comfort, and strong low‑speed torque. They are ideal for clean‑environment and multi‑shift operations. Are these forklifts CSA‑certified? Yes — all 4‑wheel electric forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. What battery options are available? Units can be supplied with lead‑acid, AGM, or lithium‑ion batteries. Lithium‑ion provides fast charging, zero maintenance, and multi‑shift performance. What capacities and lift heights are available? Typical 4‑wheel electric forklifts range from 3,000–12,000 lb with mast heights from 189″–300″+, depending on model and configuration. Are electric forklifts suitable for cold storage? Yes — cold‑storage‑rated electric forklifts with heated controllers, sealed electronics, and low‑temperature hydraulic fluids are available. Do you offer chargers and battery maintenance programs? Yes — Premier Lift Equipment provides new, used, and reconditioned chargers, along with battery maintenance, watering systems, and lithium‑ion upgrade programs.

- Equipment Types Included

- 4‑Wheel Electric Forklifts • High‑Capacity Electric Forklifts • Freezer‑Rated Electric Forklifts • Multi‑Shift Electric Forklifts • Indoor Counterbalance Forklifts

LP Gas cushion tire forklifts are engineered for indoor warehouses, dock work, production lines, ...

Discover moreLP Gas Cushion Tire Forklifts – CSA‑Certified Indoor IC Forklifts | 3,000–12,000 lb (Brampton, ON)

- Category Overview

- This page represents our Propane Cushion‑Tire Forklift category with multiple capacity and mast height options. Use it to compare models, understand lift capacities, and match mast height, turning radius, and tire type to indoor warehouse applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a propane cushion‑tire forklift? A propane cushion‑tire forklift is a sit‑down counterbalance unit powered by LPG, designed for smooth indoor warehouse floors and tight maneuvering. What applications are these forklifts best suited for? They are ideal for indoor warehousing, manufacturing, distribution centers, and dock operations where strong lifting performance and quick travel speeds are required. What capacities and mast heights are available? This category includes multiple capacity ranges (3,000–15,500 lb) and mast heights from 189″–240″+, depending on model and configuration. Why choose cushion tires for indoor IC forklifts? Cushion tires provide a smaller turning radius and excellent maneuverability on smooth concrete floors, making them ideal for tight warehouse layouts. Are these forklifts CSA‑certified? Yes. All propane cushion‑tire IC forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Can these forklifts be used outdoors? They can operate on smooth pavement, but cushion tires are not suitable for gravel, uneven surfaces, or rough terrain. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major IC forklift brands.

- Supported Manufacturers

- Toyota, Hyster, Yale, Crown, Clark, Komatsu, Nissan/UniCarriers, Linde

Multi‑Directional Internal Combustion Forklifts are engineered for long‑load handling in narrow a...

Discover moreMulti‑Directional Internal Combustion Forklifts (4‑Directional) – Long‑Load Handling | 3,000–17,500 lb | CSA‑Certified

- Category Overview

- This page represents our Very Narrow Aisle (VNA) Forklift category. Use it to compare models, understand lift heights, aisle requirements, and operator‑up functionality, and match equipment to high‑density warehouse storage. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a VNA forklift? A Very Narrow Aisle (VNA) forklift is designed to operate in extremely tight warehouse aisles, typically 5–6 feet wide, using wire guidance or rail guidance for precise navigation. What types of VNA forklifts are included in this category? This category includes man‑up turret trucks, swing‑reach trucks, and wire‑guided order pickers designed for high‑level pallet handling and dense racking systems. What applications are VNA forklifts best suited for? They are ideal for high‑bay warehouses, distribution centers, and operations where maximizing pallet positions and vertical storage is critical. What lift heights and capacities are available? Typical VNA units range from 3,000–4,500 lb with lift heights from 240″–500″+, depending on mast configuration and model. Do VNA forklifts require guidance systems? Most VNA forklifts use wire guidance or rail guidance to maintain stability and precision in extremely narrow aisles. Are these units CSA‑certified? Yes. All VNA forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Can VNA forklifts operate outside of narrow aisles? They can travel outside the aisle for staging, but they are optimized for guided aisle operation and not intended for dock work or rough surfaces. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major VNA forklift brands.

- Supported Manufacturers

- Combilift, Aisle‑Master, Hubtex, Bulmor, Raymond, Toyota, Hyster, Yale

This Royal TA200B is a heavy‑duty 20,000 lb LPG forklift built for industrial environments where ...

Discover more1996 Royal TA200B High‑Capacity Cushion Tire Forklift | 20,000 lb LPG | Standard Mast | Side‑Shift & Fork Positioner | Brampton ON

- Capacity

- 20,000 lb

- Power Type

- LPG

- Mast Spec

- 105"/121"

Environmental & Facility Safety Systems include all CSA‑approved and WHMIS‑aligned tools used to ...

Discover moreEnvironmental & Facility Safety Systems – CSA‑Approved Spill Control, Hazard‑Zone Identification & Facility‑Wide Safety Tools

- Category Overview

- This page represents our Environmental Safety Systems category. Use it to compare spill‑control products, air‑quality solutions, hazardous‑material containment tools, and environmental‑protection systems designed for warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include spill kits, absorbents, containment berms, ventilation tools, air‑quality monitors, drain‑protection devices, and hazardous‑material storage solutions. All systems are selected to reduce environmental risk, support regulatory compliance, and maintain safe, CSA‑aligned facility operations. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of environmental‑safety products are included in this category? This category includes spill kits, absorbents, containment berms, air‑quality monitors, ventilation tools, drain‑protection devices, and hazardous‑material storage solutions. Why is environmental safety important in warehouse and industrial operations? Environmental‑safety systems reduce spill risk, protect air quality, prevent contamination, and support CSA‑aligned and regulatory compliance. Do you offer spill‑control and containment products? Yes. Spill kits, absorbents, neutralizers, containment berms, and spill‑response tools are available for a wide range of industrial materials. Are air‑quality or ventilation solutions available? Yes. Air‑quality monitors, hydrogen‑gas detectors, ventilation systems, and airflow‑monitoring tools are available for enclosed or high‑risk areas. Do you supply hazardous‑material storage solutions? Yes. Flammable‑storage cabinets, corrosive‑material cabinets, and compliant containment systems are available for regulated materials. Are these products suitable for all facility types? Yes. Environmental‑safety systems are suitable for warehouses, 3PL operations, manufacturing plants, cold storage, and industrial facilities. Do these tools support CSA‑aligned safety practices? Yes. All products are selected to support environmental‑protection requirements aligned with CSA and regulatory expectations. Do you provide installation or compliance guidance? Yes. Premier Lift Equipment offers installation support, environmental‑safety planning, and compliance‑aligned guidance. Do you ship environmental‑safety products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse environments, industrial facilities, and CSA/MOL/WHMIS safety‑program requirements.

Warehouse Lighting & High‑Visibility Systems include all CSA‑approved lighting and visibility too...

Discover moreWarehouse Lighting & High‑Visibility Systems – CSA‑Approved Aisle Lighting, Task Illumination & Visibility Enhancements

- Category Overview

- This page represents our Warehouse Lighting & High‑Visibility Systems category. Use it to compare aisle‑lighting solutions, task‑illumination tools, high‑visibility fixtures, and visibility‑enhancement systems designed for warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include LED aisle lights, task lights, motion‑activated fixtures, emergency lighting, pedestrian‑zone visibility tools, and high‑output illumination systems for mixed‑traffic environments. All solutions are selected to improve visibility, reduce collision risk, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of lighting and visibility products are included in this category? This category includes LED aisle lights, task‑illumination fixtures, motion‑activated lighting, emergency lighting, and high‑visibility warehouse lighting systems. Why is proper warehouse lighting important? Effective lighting improves visibility, reduces collision risk, enhances operator awareness, and supports CSA‑aligned safe‑operation practices. Do you offer aisle‑lighting and task‑illumination systems? Yes. Aisle‑lighting systems, task lights, and high‑output fixtures are available for picking zones, racking aisles, and mixed‑traffic areas. Are motion‑activated or energy‑efficient options available? Yes. Motion‑activated, daylight‑harvesting, and energy‑efficient LED systems are available to reduce operating costs and improve visibility. Do you supply lighting for pedestrian‑zone visibility? Yes. Pedestrian‑zone visibility lights, walkway‑illumination tools, and high‑visibility indicators are available for high‑risk areas. Do you offer emergency or backup lighting? Yes. Emergency lighting, exit signs, and backup illumination systems are available for compliance and safety‑critical environments. Are these lighting systems suitable for all facility types? Yes. Lighting solutions are available for warehouses, 3PL operations, manufacturing plants, cold storage, and industrial facilities. Do you provide installation or upgrade support? Yes. Premier Lift Equipment offers installation, lighting‑layout guidance, and upgrade support for warehouse lighting systems. Do you ship lighting products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse layouts, racking systems, forklifts, and CSA/MOL visibility‑safety requirements.

Dock Communication & Alert Systems include all CSA‑approved visual and audible safety tools used ...

Discover moreDock Communication & Alert Systems – CSA‑Approved Visual, Audible & Trailer‑Presence Safety Tools

- Category Overview

- This page represents our Dock Communication & Alert Systems category. Use it to compare visual‑alert tools, audible warning systems, trailer‑presence indicators, and dock‑area communication products designed to support safe loading and unloading operations. Products include dock signal lights, interior/exterior communication lights, audible alarms, trailer‑presence sensors, motion‑activated alerts, and dock‑status indicators used in warehouses, 3PL operations, manufacturing plants, and industrial yards. All solutions are selected to improve visibility, enhance communication between drivers and dock staff, and support CSA‑aligned dock‑safety practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of dock communication systems are included in this category? This category includes dock signal lights, interior/exterior communication lights, audible alarms, trailer‑presence sensors, and dock‑status indicators. Why are communication and alert systems important at loading docks? They improve visibility, enhance communication between drivers and dock staff, prevent premature departure, and support CSA‑aligned dock‑safety practices. Do you offer trailer‑presence or motion‑activated alert systems? Yes. Trailer‑presence indicators, motion‑activated alerts, and sensor‑based warning systems are available for high‑risk dock areas. Are interior and exterior dock lights available? Yes. Red/green communication lights, dock‑status indicators, and visual‑alert systems are available for both inside and outside the dock bay. Do you supply audible alarms for dock operations? Yes. Audible warning devices, departure alarms, and hazard‑alert systems are available for mixed‑traffic and high‑noise environments. Are these systems compatible with all dock types? Yes. Dock communication and alert systems are suitable for standard docks, recessed docks, drive‑in docks, and yard‑truck operations. Do these tools support CSA‑aligned safety practices? Yes. All products are selected to enhance visibility, communication, and hazard awareness in accordance with CSA‑aligned dock‑safety expectations. Do you provide installation or dock‑layout guidance? Yes. Premier Lift Equipment offers installation, layout planning, and dock‑safety system integration support. Do you ship dock‑communication products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all dock‑levelers, trailers, yard trucks, warehouse doors, and CSA/MOL dock‑area safety requirements.

Pedestrian‑Zone Safety Systems include all CSA‑approved walkway‑control and collision‑prevention ...

Discover morePedestrian‑Zone Safety Systems – CSA‑Approved Walkway Control, Collision‑Prevention & High‑Visibility Safety Tools

- Category Overview

- This page represents our Pedestrian‑Zone Safety Systems category. Use it to compare walkway‑control tools, collision‑prevention systems, visual‑guidance products, and high‑visibility safety solutions designed to protect pedestrians in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include pedestrian‑warning lights, floor‑marking systems, zone‑lighting tools, intersection‑safety devices, visual‑alert systems, and mixed‑traffic safety solutions. All systems are selected to improve visibility, reduce collision risk, and support CSA‑aligned pedestrian‑safety practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of pedestrian‑zone safety products are included in this category? This category includes pedestrian‑warning lights, floor‑marking systems, zone‑lighting tools, intersection‑safety devices, and visual‑alert systems. Why are pedestrian‑zone safety systems important? They reduce collision risk, improve visibility, guide foot traffic, and support CSA‑aligned safety practices in mixed‑traffic environments. Do you offer visual‑alert or warning‑light systems? Yes. Options include pedestrian‑warning lights, zone‑lighting tools, and visual‑alert indicators for high‑traffic areas. Are floor‑marking and walkway‑control products available? Yes. Floor tape, hazard markers, walkway dividers, and visual‑guidance systems are available for controlled pedestrian movement. Do you supply intersection‑safety devices? Yes. Intersection‑alert systems, corner‑visibility tools, and motion‑activated warning devices are available for blind‑spot areas. Are these products compatible with all warehouse layouts? Yes. Pedestrian‑zone safety systems are modular and can be configured for aisles, intersections, docks, and custom facility layouts. Do these tools support CSA‑aligned safety practices? Yes. All products are selected to enhance visibility, guide pedestrian flow, and reduce collision risk in accordance with CSA‑aligned safety expectations. Do you provide installation or layout guidance? Yes. Premier Lift Equipment offers installation, layout planning, and pedestrian‑zone design support. Do you ship pedestrian‑zone safety products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse layouts, forklift fleets, pedestrian walkways, and CSA/MOL safety‑zone requirements.

Warehouse Barriers & Fencing includes all CSA‑approved impact‑protection and pedestrian‑zone safe...

Discover moreWarehouse Barriers & Fencing – CSA‑Approved Impact Protection & Pedestrian‑Zone Safety Systems

- Category Overview

- This page represents our Warehouse Barriers & Fencing category. Use it to compare impact‑protection systems, pedestrian‑zone barriers, modular fencing, and facility‑safety products designed to separate people from equipment and protect high‑risk areas. Products include guard rails, safety fencing, modular barrier systems, rack‑end protectors, column guards, and pedestrian‑walkway barriers used in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All solutions are selected to reduce collision risk, protect infrastructure, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of barriers and fencing are included in this category? This category includes guard rails, modular fencing, pedestrian‑zone barriers, rack‑end protectors, column guards, and impact‑protection systems. Why are barriers and fencing important in warehouse environments? Barriers and fencing separate pedestrians from equipment, protect infrastructure, reduce collision risk, and support CSA‑aligned facility‑safety practices. Do you offer guard rails and impact‑protection systems? Yes. Heavy‑duty guard rails, modular barrier systems, and impact‑rated protection products are available for high‑traffic areas. Are pedestrian‑walkway barriers available? Yes. Pedestrian‑zone barriers, walkway dividers, and visual‑guidance systems are available for mixed‑traffic environments. Do you supply fencing for restricted or high‑risk areas? Yes. Modular fencing systems are available for machine zones, battery rooms, equipment areas, and controlled‑access spaces. Are these products compatible with all warehouse layouts? Yes. Barriers and fencing systems are modular and can be configured for aisles, docks, corners, and custom facility layouts. Do these tools support CSA‑aligned safety practices? Yes. Barriers and fencing support CSA‑aligned facility‑safety requirements by reducing collision risk and improving pedestrian separation. Do you provide installation or layout guidance? Yes. Premier Lift Equipment offers installation, layout planning, and safety‑zone design support. Do you ship barriers and fencing across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse racking, dock‑levelers, forklift fleets, pedestrian walkways, and industrial safety infrastructure.

Wheel Chocks (Dock & Yard Safety) includes all CSA‑approved trailer‑restraint and roll‑away preve...

Discover moreWheel Chocks (Dock & Yard Safety) – CSA‑Approved Trailer Restraint & Roll‑Away Prevention Systems

- Category Overview

- This page represents our Wheel Chocks category. Use it to compare CSA‑approved trailer‑restraint tools, roll‑away‑prevention systems, and dock‑safety products designed for warehouses, 3PL operations, manufacturing plants, and industrial yards. Products include rubber and urethane wheel chocks, heavy‑duty trailer chocks, chain‑restrained systems, dock‑position indicators, and yard‑safety accessories used to secure trailers during loading and unloading. All solutions are selected to prevent trailer movement, reduce dock‑area hazards, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of wheel chocks are included in this category? This category includes rubber wheel chocks, urethane wheel chocks, heavy‑duty trailer chocks, chain‑restrained systems, and dock‑area roll‑away‑prevention tools. Why are wheel chocks important for dock safety? Wheel chocks prevent trailer movement during loading and unloading, reducing roll‑away risk and supporting CSA‑aligned dock‑safety practices. Do you offer heavy‑duty trailer chocks for transport trucks? Yes. Heavy‑duty chocks are available for transport trailers, yard trucks, and industrial vehicles. Are chain‑restrained or tethered chocks available? Yes. Chain‑restrained and tethered chocks are available to prevent loss, improve compliance, and ensure consistent dock‑area use. Do you supply wheel chocks for uneven or outdoor surfaces? Yes. Outdoor‑rated and high‑traction chocks are available for gravel, asphalt, and yard environments. Are these products compatible with all trailer types? Yes. Wheel chocks are suitable for standard trailers, container chassis, yard trucks, and industrial vehicles. Do these tools support CSA‑aligned safety practices? Yes. Wheel chocks support CSA‑aligned dock‑safety requirements by preventing unintended trailer movement. Do you provide installation or dock‑safety guidance? Yes. Premier Lift Equipment offers guidance on dock‑safety setup, signage placement, and compliance practices. Do you ship wheel chocks across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all trailers, dock‑levelers, yard trucks, forklifts, and warehouse loading‑bay infrastructure.

Dock Safety & Lighting covers all CSA‑approved lighting and visibility systems used in loading ba...

Discover moreDock Safety & Lighting – CSA‑Approved Loading‑Bay Visibility & Protection Systems

- Category Overview

- This page represents our Warehouse Lighting category. Use it to compare high‑visibility, energy‑efficient lighting systems designed for warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include LED high‑bay fixtures, task lighting, aisle‑lighting systems, motion‑activated fixtures, emergency lighting, and visibility‑enhancing upgrades for forklift and pedestrian zones. All solutions are selected to improve visibility, reduce energy consumption, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of lighting products are included in this category? This category includes LED high‑bay fixtures, task lighting, aisle‑lighting systems, motion‑activated fixtures, emergency lighting, and visibility‑enhancing warehouse lighting solutions. Why is proper warehouse lighting important? Effective lighting improves visibility, reduces collision risk, enhances operator awareness, and supports CSA‑aligned safe‑operation practices. Do you offer LED high‑bay lighting? Yes. LED high‑bay fixtures are available for warehouses, distribution centers, and industrial facilities requiring high‑output illumination. Are motion‑activated or energy‑efficient options available? Yes. Motion‑activated, daylight‑harvesting, and energy‑efficient LED systems are available to reduce operating costs and improve visibility. Do you supply lighting for forklift or pedestrian zones? Yes. Aisle‑lighting systems, task lighting, and visibility‑enhancing fixtures are available for mixed‑traffic areas and high‑risk zones. Do you offer emergency or backup lighting? Yes. Emergency lighting, exit signs, and backup illumination systems are available for compliance and safety‑critical environments. Are these lighting systems suitable for all facility types? Yes. Lighting solutions are available for warehouses, 3PL operations, manufacturing plants, cold storage, and industrial facilities. Do you provide installation or upgrade support? Yes. Premier Lift Equipment offers installation, lighting‑layout guidance, and upgrade support for warehouse lighting systems. Do you ship lighting products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all dock equipment, forklifts, pallet trucks, and warehouse infrastructure.

Forklift Safety Accessories include all CSA‑approved operator‑protection, visibility, and on‑truc...

Discover moreForklift Safety Accessories – CSA‑Approved Operator‑Protection, Visibility & On‑Truck Safety Tools

- Category Overview

- This page represents our Forklift Safety Accessories category. Use it to compare operator‑protection tools, visibility enhancements, warning systems, and on‑truck safety accessories designed to support CSA‑aligned forklift operation. Products include blue/red safety lights, alarms, strobe lights, mirrors, cameras, seat‑belt systems, overhead‑guard accessories, and pedestrian‑awareness tools used in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All solutions are selected to improve visibility, reduce collision risk, and support safe, compliant forklift operation. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of forklift safety accessories are included in this category? This category includes blue/red safety lights, alarms, strobe lights, mirrors, cameras, seat‑belt systems, overhead‑guard accessories, and pedestrian‑awareness tools. Why are forklift safety accessories important? Safety accessories improve visibility, reduce collision risk, support operator awareness, and help maintain CSA‑aligned safe‑operation practices. Do you offer forklift‑mounted visibility tools? Yes. Options include blue/red spotlights, strobe lights, rear‑facing lights, and wide‑angle visibility mirrors. Are pedestrian‑awareness systems available? Yes. Visual warning systems, zone‑lighting tools, and awareness indicators are available for mixed‑traffic environments. Do you supply operator‑protection accessories? Yes. Seat‑belt systems, overhead‑guard accessories, and operator‑station safety tools are available for most forklift models. Are these accessories compatible with all forklift brands? Yes. Most forklift‑mounted safety accessories are universal or available with model‑specific mounting options. Do these products support CSA‑aligned safety practices? Yes. All accessories are selected to support visibility, awareness, and operator‑protection requirements aligned with CSA B335. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and integration support for forklift safety accessories. Do you ship forklift safety accessories across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, mast types, carriage classes, and CSA/MOL operator‑safety requirements.

CSA Certification & Inspection Services include all CSA/MOL‑aligned inspection, documentation, an...

Discover moreCSA Certification & Inspection Services – CSA/MOL Compliance, Annual Safety Audits & Equipment‑Certification Programs

- Category Overview

- This page represents our CSA Certification & Inspection Services category. Use it to compare CSA/MOL‑aligned inspection programs, annual safety audits, equipment‑certification services, and compliance documentation for forklifts, aerial lifts, battery rooms, and warehouse operations. Services include on‑site inspections, certification renewals, safety‑system evaluations, and audit‑ready reporting designed to support regulatory compliance in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All programs are delivered by certified technicians and structured to maintain safe, compliant, and fully documented equipment fleets. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of certification and inspection services are included in this category? This category includes CSA‑aligned equipment inspections, annual safety audits, certification renewals, compliance documentation, and safety‑system evaluations. Why are CSA certifications important? CSA certifications verify that equipment meets safety standards, supports MOL compliance, and ensures operators are using properly inspected and approved machinery. Do you offer on‑site inspections? Yes. Certified technicians provide on‑site inspections for forklifts, aerial lifts, battery rooms, and warehouse safety systems. What equipment can be certified? Forklifts, reach trucks, order pickers, walkies, aerial lifts, tow tractors, and other material‑handling equipment can be certified or recertified. Do you provide annual or scheduled safety audits? Yes. Annual, semi‑annual, and custom audit programs are available for facilities requiring ongoing compliance tracking. Do you supply documentation for MOL or internal audits? Yes. Inspection reports, certification records, and compliance documentation are provided in audit‑ready formats. Are certification services compatible with all equipment brands? Yes. Certification and inspection services apply to all major forklift and aerial‑lift brands. Do you offer guidance on setting up compliance programs? Yes. Premier Lift Equipment provides support for establishing inspection routines, documentation workflows, and CSA‑aligned compliance practices. Do you offer fleet‑wide certification programs? Yes. Multi‑unit and multi‑facility certification programs are available for warehouses, 3PL operations, and industrial fleets. Do you provide service across Canada and the United States? Yes. Certification and inspection services are available across Canada, with extended support options for U.S. facilities.

- Supported Manufacturers

- Supported Manufacturers

Forklift Stability & Load‑Handling Safety includes all CSA‑approved tools used to improve load co...

Discover moreForklift Stability & Load‑Handling Safety – CSA‑Approved Load Control, Stability Tools & Mast‑Tilt Safety Systems

- Category Overview

- This page represents our Forklift Stability & Load‑Handling Safety category. Use it to compare load‑control tools, stability‑enhancing accessories, mast‑tilt safety systems, and operator‑awareness products designed to support safe lifting practices in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include load backrests, tilt‑indicators, stability‑assist tools, load‑weight indicators, and accessories that help operators maintain proper load balance and visibility. All solutions are selected to reduce tip‑over risk, improve load control, and support CSA‑aligned safe‑operation standards. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of stability and load‑handling tools are included in this category? This category includes load backrests, mast‑tilt indicators, load‑weight indicators, stability‑assist tools, and accessories that support safe lifting and load control. Why is forklift stability important? Stability is critical for preventing tip‑overs, maintaining load balance, and ensuring safe operation in high‑traffic or uneven‑surface environments. Do you offer load backrests? Yes. Load backrests are available for most forklift models to help secure loads and prevent product from shifting toward the operator. Are mast‑tilt or angle‑indicators available? Yes. Mast‑tilt indicators and angle‑gauges help operators maintain proper mast position during lifting, stacking, and travel. Do you supply load‑weight or overload indicators? Yes. Load‑weight indicators and overload‑alert systems are available to help operators avoid exceeding rated capacity. Are these products compatible with all forklift brands? Yes. Most stability and load‑handling accessories are universal or available with model‑specific mounting options. Do these tools support CSA‑aligned safety practices? Yes. Stability and load‑handling accessories support CSA‑aligned safe‑operation standards by improving operator awareness and reducing risk. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and integration support for stability and load‑handling accessories. Do you ship these products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, mast types, carriage sizes, and CSA/MOL load‑handling requirements.

Operator Protection & Ergonomics includes all CSA‑approved comfort, safety, and fatigue‑reduction...

Discover moreOperator Protection & Ergonomics – CSA‑Approved Comfort, Safety & Fatigue‑Reduction Systems

- Category Overview

- This page represents our Operator Protection & Ergonomics category. Use it to compare comfort‑enhancing, fatigue‑reducing, and safety‑focused accessories designed to support forklift operators in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include operator fans, suspension seats, ergonomic mats, cab enclosures, weather‑protection systems, vibration‑reduction components, and safety‑enhancing visibility tools. All solutions are selected to improve operator comfort, reduce strain, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of operator‑protection products are included in this category? This category includes suspension seats, operator fans, ergonomic mats, cab enclosures, weather‑protection systems, and vibration‑reduction accessories. Why is operator ergonomics important? Ergonomic equipment reduces fatigue, improves comfort, supports longer shifts, and helps operators maintain safe, consistent performance. Do you offer suspension or comfort‑enhanced seating? Yes. Suspension seats, high‑back seats, and comfort‑enhanced seating options are available for most forklift brands. Are cab enclosures or weather‑protection systems available? Yes. Soft and hard cab enclosures, heaters, and weather‑protection systems are available for indoor/outdoor operations. Do these products support CSA‑aligned safety practices? Yes. Ergonomic and protection accessories help operators maintain visibility, posture, and control, supporting CSA‑aligned safe‑operation standards. Are these products compatible with all forklift brands? Yes. Most operator‑protection and ergonomic accessories are universal or available with model‑specific mounting options. Do you offer vibration‑reduction or fatigue‑reduction tools? Yes. Options include anti‑vibration mats, ergonomic floor pads, and comfort‑enhancing operator‑station upgrades. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and integration support for operator‑protection accessories. Do you ship operator‑protection products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, warehouse vehicles, and CSA/MOL operator‑safety requirements.

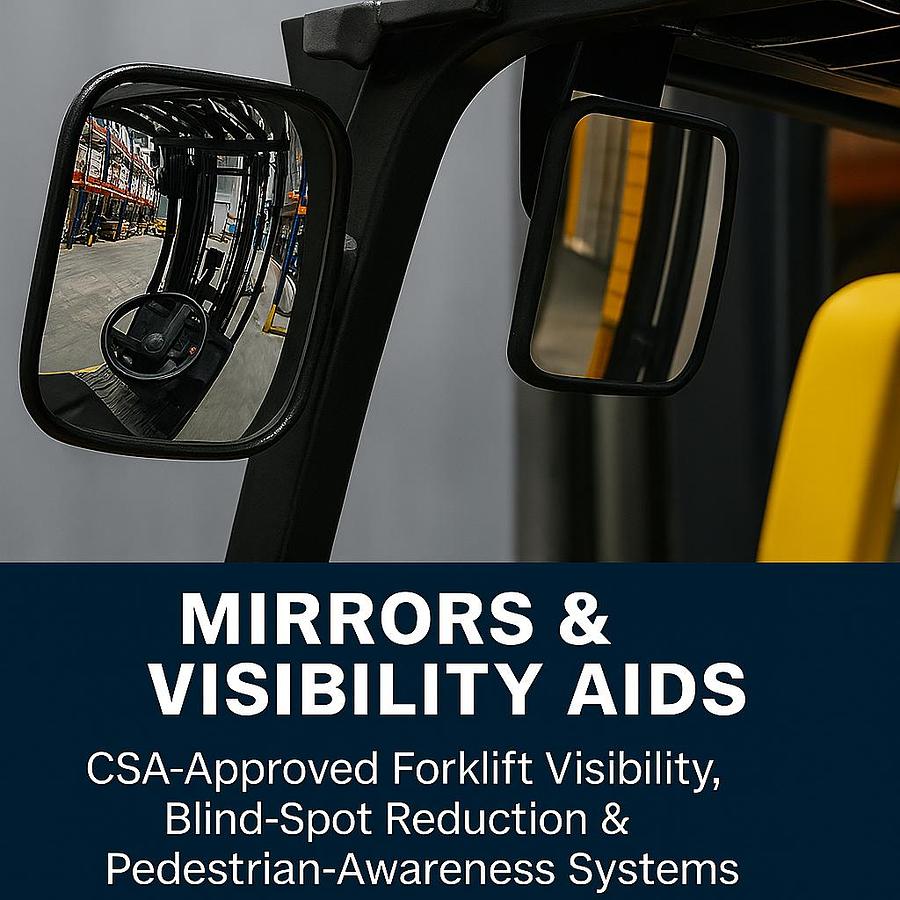

Mirrors & Visibility Aids include all CSA‑approved visibility tools used to reduce blind spots, i...

Discover moreMirrors & Visibility Aids – CSA‑Approved Forklift Visibility, Blind‑Spot Reduction & Pedestrian‑Awareness Systems

- Category Overview

- This page represents our Mirrors & Visibility Aids category. Use it to compare forklift‑mounted mirrors, convex mirrors, dome mirrors, pedestrian‑awareness systems, and visibility tools designed to reduce blind spots and improve operator awareness in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products support CSA‑aligned visibility requirements and help prevent collisions in high‑traffic and mixed‑pedestrian environments. All solutions are selected to enhance sightlines, improve hazard detection, and support safe material‑handling workflows. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of visibility aids are included in this category? This category includes forklift‑mounted mirrors, convex mirrors, dome mirrors, pedestrian‑awareness systems, and blind‑spot reduction tools. Why are visibility aids important for forklift operations? Visibility aids reduce blind spots, improve operator awareness, and help prevent collisions in high‑traffic warehouse environments. Do you offer forklift‑mounted mirrors? Yes. Options include overhead guards mirrors, side‑mount mirrors, rear‑view mirrors, and wide‑angle visibility mirrors. Are convex and dome mirrors available for facility installation? Yes. Convex and dome mirrors are available for intersections, blind corners, and high‑traffic pedestrian zones. Do these products support CSA‑aligned safety practices? Yes. Visibility aids support CSA‑aligned operational safety by improving sightlines and reducing collision risk. Are these products compatible with all forklift brands? Yes. Most forklift‑mounted mirrors and visibility tools are universal or available with model‑specific mounting options. Do you offer pedestrian‑awareness systems? Yes. Options include visual warning systems, zone‑lighting tools, and awareness indicators for mixed‑traffic areas. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and safety‑equipment integration support. Do you ship visibility products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, warehouse vehicles, pedestrian‑safety systems, and CSA/MOL visibility requirements.

Inspection Logs & Compliance Systems include all CSA‑approved documentation tools used to support...

Discover moreInspection Logs & Compliance Systems – CSA‑Approved Checklists, Safety Documentation & Audit‑Ready Recordkeeping

- Category Overview

- This page represents our Inspection Logs & Compliance Systems category. Use it to compare CSA‑approved checklists, digital and paper inspection logs, safety documentation tools, and audit‑ready recordkeeping systems for forklifts, aerial lifts, battery rooms, and warehouse operations. Products support daily pre‑shift inspections, maintenance tracking, incident documentation, and regulatory compliance for warehouses, 3PL operations, manufacturing plants, and industrial facilities. All solutions are designed to improve visibility, reduce risk, and maintain consistent, audit‑ready safety records. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of inspection and compliance tools are included in this category? This category includes CSA‑approved checklists, daily inspection books, digital log systems, maintenance record forms, incident documentation tools, and audit‑ready compliance binders. Why are inspection logs important? Inspection logs support CSA‑aligned pre‑shift checks, reduce equipment‑related risks, and provide documented proof of compliance during audits or investigations. Do you offer forklift‑specific inspection books? Yes. Forklift inspection books are available for electric, propane, diesel, reach trucks, order pickers, walkies, and aerial lifts. Are digital inspection systems available? Yes. Digital log systems and cloud‑based recordkeeping tools are available for facilities transitioning away from paper documentation. Do these tools help with MOL or internal audits? Yes. Inspection logs and compliance systems provide structured, audit‑ready documentation that supports MOL reviews and internal safety audits. Do you offer battery‑room inspection and compliance tools? Yes. Battery‑room checklists, eyewash inspection logs, spill‑response documentation, and charging‑zone compliance forms are available. Are these products compatible with all equipment brands? Yes. Inspection logs and compliance systems are universal and suitable for all forklift and material‑handling equipment brands. Do you provide training or guidance on implementing compliance systems? Yes. Premier Lift Equipment offers guidance on setting up inspection routines, documentation workflows, and CSA‑aligned compliance practices. Do you ship compliance products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, aerial lifts, warehouse equipment, and CSA/MOL inspection protocols.

Battery Room Safety includes all CSA‑approved spill‑response, PPE, eyewash, ventilation, and char...

Discover moreBattery Room Safety – CSA‑Approved Spill Response, PPE & Charging‑Zone Compliance Systems

- Category Overview

- This page represents our Battery Room Safety category. Use it to compare spill‑response kits, PPE, ventilation solutions, eyewash stations, signage, and charging‑zone compliance tools designed for CSA‑aligned battery‑handling environments. Products support safe charging, watering, maintenance, and emergency response for industrial forklift batteries in warehouses, 3PL operations, manufacturing plants, and distribution centers. All equipment is selected to reduce risk, improve visibility, and maintain compliance in high‑hazard battery‑charging areas. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of safety products are included in this category? This category includes spill‑response kits, PPE, eyewash stations, ventilation solutions, acid‑resistant flooring, signage, and charging‑zone compliance tools. Why is battery room safety important? Battery rooms contain corrosive electrolytes, hydrogen‑gas risks, and high‑current charging equipment. Proper safety tools reduce hazards and support CSA‑aligned compliance. Do you offer spill‑response and neutralization kits? Yes. Spill kits, neutralizing agents, absorbents, and acid‑resistant cleanup tools are available for emergency response. What PPE is required in battery‑charging areas? Common PPE includes face shields, chemical‑resistant gloves, aprons, safety eyewear, and footwear designed for corrosive environments. Do you supply eyewash or emergency‑shower stations? Yes. Portable and plumbed eyewash stations are available for battery‑handling and spill‑risk areas. Do you offer ventilation or hydrogen‑gas monitoring solutions? Yes. Ventilation systems, hydrogen‑gas detectors, and airflow‑monitoring tools are available for enclosed charging rooms. Are these products compatible with all industrial battery types? Yes. Safety equipment is suitable for lead‑acid, AGM, gel, and lithium‑ion battery environments. Do you provide installation or compliance support? Yes. Premier Lift Equipment offers installation, inspections, and guidance for CSA‑aligned battery‑room compliance. Do you ship battery‑room safety equipment across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift battery chargers, industrial batteries, watering systems, and charging‑station infrastructure.

Material Handling Safety Equipment includes visibility, protection, compliance, and dock‑safety s...

Discover moreMaterial Handling Safety Equipment – CSA‑Approved Visibility, Protection & Compliance Tools

- Category Overview

- This page represents our Material Handling Safety Equipment category. Use it to compare visibility tools, pedestrian‑protection systems, forklift safety accessories, and facility‑protection products designed to support CSA‑aligned warehouse operations. Equipment options include blue/red safety lights, alarms, mirrors, cameras, guard rails, bollards, rack protectors, dock‑area safety products, and pedestrian‑awareness systems used in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All products are selected to improve visibility, reduce collision risk, and support safe, compliant material‑handling workflows. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of safety equipment are included in this category? This category includes forklift‑mounted safety accessories, pedestrian‑awareness systems, guard rails, bollards, rack protectors, mirrors, alarms, dock‑area safety products, and visibility tools. Why is safety equipment important in material‑handling environments? Safety equipment reduces collision risk, improves visibility, protects pedestrians, and supports CSA‑aligned warehouse and industrial operations. Do you offer forklift‑mounted safety accessories? Yes. Options include blue/red safety lights, alarms, strobe lights, mirrors, cameras, and pedestrian‑awareness systems. Do you supply facility‑protection products? Yes. Guard rails, bollards, column protectors, rack protectors, and dock‑area safety products are available for high‑traffic and high‑risk areas. Are these products compatible with all forklift brands? Yes. Most forklift‑mounted safety accessories are universal or available with model‑specific mounting options. Do you offer installation or service support? Yes. Premier Lift Equipment provides installation, inspections, repairs, and safety‑equipment integration support. Do you ship safety equipment across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions. What industries typically use this equipment? Warehousing, 3PL, manufacturing, food distribution, retail, automotive, and industrial facilities.

- Supported Manufacturers

- Toyota · Raymond · Crown · Hyster · Yale · Cat · Mitsubishi · UniCarriers · Clark · Komatsu · Hyundai · Hangcha · BYD · Linde · STILL · Doosan · Bendi · Combilift · Drexel · Skyjack · Genie

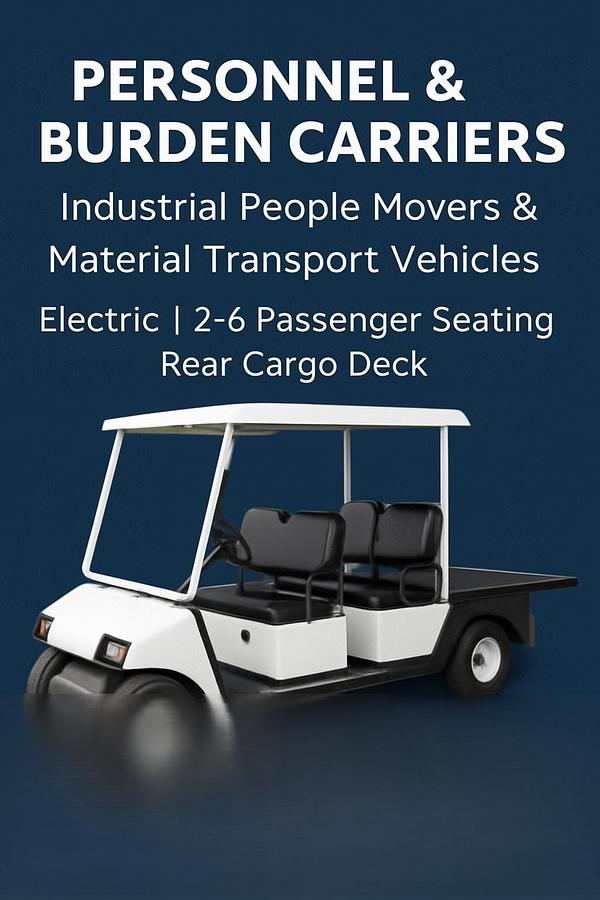

Personnel & burden carriers are electric industrial utility vehicles engineered for safe, efficie...

Discover morePersonnel & Burden Carriers – 2–6 Passenger Electric Utility Vehicles

- Category Overview

- This page represents our Personnel & Burden Carriers category. Use it to compare electric utility vehicles designed for transporting people, tools, and materials across large facilities. Equipment options include 2–6 passenger personnel carriers, flat‑deck and cargo‑box burden carriers, and tow‑capable utility vehicles with 500–3,000 lb capacity. All units are fully serviced, CSA‑ready, and configured for safe, efficient movement in warehouses, plants, airports, campuses, hospitals, and industrial environments. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)