Forklift tires play a bigger role in performance, safety, and operating cost than many people realize. Choosing the wrong tire type can lead to poor traction, accelerated wear, operator discomfort, and even safety issues.

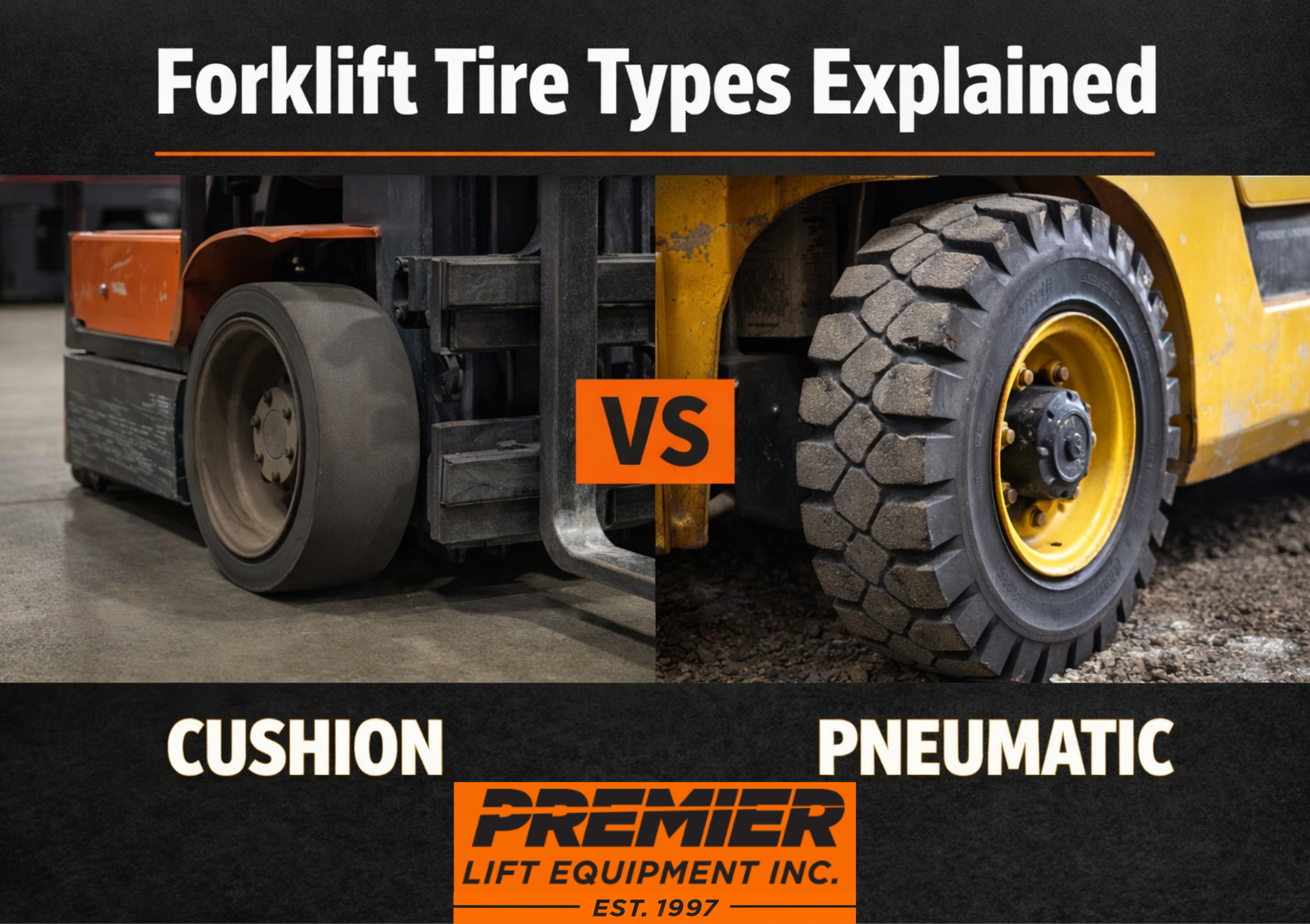

Two of the most common forklift tire types are cushion tires and pneumatic tires. While they may look similar at a glance, they’re designed for very different environments and applications.

Here’s a clear breakdown to help you choose the right option for your operation.

What Are Cushion Tires?

Cushion tires are solid rubber tires that are pressed onto a metal band and mounted directly onto the forklift’s drive wheels. They’re smaller in diameter and have a smooth or lightly treaded surface.

Cushion tires are almost exclusively used indoors, particularly in warehouses and manufacturing facilities with smooth concrete floors.

Because they’re solid, cushion tires don’t puncture and require minimal maintenance. Their smaller size also allows forklifts to have a lower profile, which is helpful in areas with low overhead clearance.

However, cushion tires offer limited shock absorption. On uneven surfaces, operators will feel more vibration, and traction can become an issue if floors are wet or dusty.

Best Applications for Cushion Tires

Cushion tires are ideal for:

- Indoor warehouses

- Manufacturing plants

- Distribution centers

- Tight aisles and confined spaces

- Dock work on smooth surfaces

If your forklift never leaves the building and operates on flat, finished floors, cushion tires are often the most efficient and cost-effective choice.

What Are Pneumatic Tires?

Pneumatic tires are air-filled tires, similar to those on a car or truck. They’re larger, have deeper tread patterns, and are designed to handle rough or uneven terrain.

Because they’re air-filled, pneumatic tires absorb shock much better than cushion tires, providing improved ride comfort and stability. This makes them well-suited for outdoor use or facilities where forklifts regularly transition between indoor and outdoor environments.

The tradeoff is maintenance. Pneumatic tires can puncture and require air pressure monitoring. They also increase the forklift’s overall height and turning radius compared to cushion-tire trucks.

Best Applications for Pneumatic Tires

Pneumatic tires are best suited for:

- Outdoor yards

- Lumber and building supply facilities

- Construction materials handling

- Gravel, asphalt, or uneven surfaces

- Indoor/outdoor operations

If your forklift operates outside or crosses rough ground regularly, pneumatic tires are usually the safer and more durable option.

Cushion vs. Pneumatic: Key Differences

The biggest differences come down to surface conditions and environment.

Cushion tires excel on smooth indoor floors, offering tight maneuverability and lower operating costs. Pneumatic tires handle uneven surfaces, outdoor conditions, and debris much better, but come with higher maintenance needs.

Ride comfort also differs significantly. Pneumatic tires provide a smoother ride, while cushion tires transmit more vibration to the operator.

Solid Pneumatic Tires: A Middle Ground

Some operations choose solid pneumatic (airless) tires, which look like pneumatic tires but are made of solid rubber.

These offer:

- Better traction than cushion tires

- No risk of punctures

- More durability than air-filled tires

They’re often used in harsh environments where flats are common but shock absorption is still needed.

How Tire Choice Affects Forklift Performance

Your tire choice impacts:

- Load stability

- Braking distance

- Turning radius

- Operator comfort

- Overall forklift lifespan

Using the wrong tire type can increase wear on suspension components, steering systems, and even the mast over time.

How to Choose the Right Forklift Tire

When deciding between cushion and pneumatic tires, ask:

- Will the forklift operate indoors only or outdoors as well?

- Are the floors smooth or uneven?

- Is debris, gravel, or moisture present?

- How important is tight maneuverability?

- What level of maintenance can your operation support?

There’s no “better” tire—only the right tire for your environment.

Forklift tires are not a one-size-fits-all decision. Cushion tires are perfect for smooth indoor warehouses, while pneumatic tires are built for outdoor and rough-surface work. Choosing correctly improves safety, reduces downtime, and extends the life of your equipment.

At Premier Lift Equipment, we help customers select, inspect, and maintain forklift tires based on how their equipment is actually used—not just what’s cheapest upfront. If you’re unsure which tire type fits your operation, our team can help you make the right call before wear or damage becomes a problem.

👉 Schedule a tire inspection or fleet assessment

👉 Talk to our team about the right forklift tires for your operation

👉 Browse our CSA-certified forklifts and tire-ready inventory