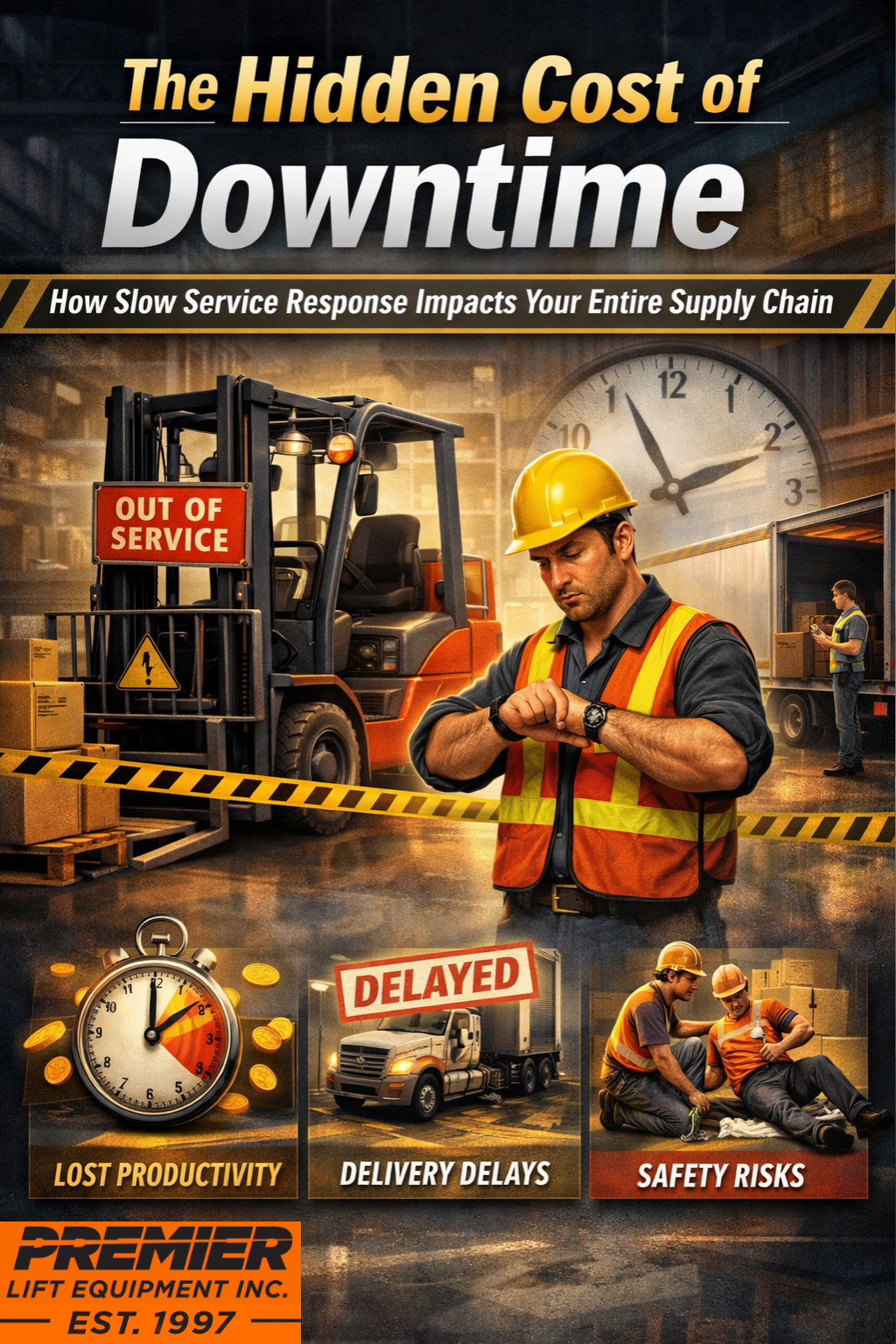

In warehouse and distribution environments, downtime is rarely treated as an emergency—until it becomes one.

A forklift goes down. A pallet truck stops charging. A reach truck starts throwing intermittent fault codes. At first, it feels manageable. But when service response is slow, that single equipment issue begins to ripple outward—impacting productivity, labour costs, delivery timelines, and ultimately customer satisfaction.

The true cost of downtime isn’t just the repair bill. It’s everything that happens while you’re waiting.

Downtime Is More Than a Broken Forklift

When lift equipment stops working, operations don’t stop. They slow down.

Operators begin sharing trucks.

Tasks get reshuffled.

Throughput drops.

Even a single unit out of service can disrupt picking schedules, loading times, and dock flow—especially in tight-shift or high-volume operations.

What seems like a small mechanical issue can quietly reduce daily output and increase labour strain across the floor.

The Labour Multiplier Effect

When equipment is unavailable, managers compensate with people.

That often means:

- Overtime hours

- Reassigning operators from other tasks

- Manual handling where powered equipment should be used

- Increased congestion and inefficiency

These short-term adjustments add hidden costs quickly. What would have been a routine service visit turns into inflated payroll and productivity loss.

Delivery Delays and Customer Impact

Supply chains are built on timing.

If loading is delayed because equipment is down:

- Trucks wait longer at the dock

- Carriers charge detention fees

- Shipments leave late

- Customers receive orders behind schedule

In competitive markets, reliability is a differentiator. Repeated service delays erode trust—not just internally, but with your customers.

The Compounding Risk to Safety

Slow service response doesn’t just impact productivity. It impacts safety.

When equipment isn’t repaired quickly, operators may:

- Continue using a truck with known issues

- Share equipment under rushed conditions

- Work around mechanical limitations

- Operate fatigued due to schedule pressure

These conditions increase the risk of collisions, product damage, and injury.

Downtime pressure creates decision-making shortcuts. That’s when incidents happen.

The Inventory Bottleneck Effect

In many facilities, equipment flow directly controls inventory flow.

When forklifts are unavailable:

- Staging areas fill up

- Aisles become congested

- Picking slows

- Replenishment lags

Over time, this creates a visible bottleneck that affects every department—from receiving to shipping.

And the longer service response takes, the more that bottleneck grows.

Why Fast Service Response Matters

A strong service partner doesn’t just “fix equipment.” They protect your operational continuity.

Fast response times mean:

- Issues are addressed before they escalate

- Minor faults don’t become major repairs

- Operators stay productive

- Safety risks are minimized

- Your supply chain remains predictable

Preventive maintenance also plays a critical role. Scheduled service reduces emergency breakdowns and keeps your fleet performing consistently.

The Real Question: What Does Downtime Actually Cost You?

Many warehouses track repair invoices—but few track:

- Lost productivity per hour

- Overtime triggered by breakdowns

- Delayed shipment penalties

- Customer dissatisfaction

- Increased safety exposure

When you calculate those factors, the cost of slow service response is almost always higher than expected.

The cheapest service provider isn’t always the least expensive option.

Building a Downtime Strategy

To protect your supply chain, consider:

- Partnering with a service provider that offers fast response times

- Tracking mean time to repair (MTTR)

- Investing in preventive maintenance programs

- Keeping critical spare equipment available

- Reviewing battery and charging infrastructure regularly

Downtime cannot always be prevented—but it can be controlled.

In today’s supply chain environment, speed and reliability are competitive advantages. Equipment downtime may start as a maintenance issue, but slow service response quickly turns it into an operational risk.

The question isn’t whether breakdowns will happen.

The question is how quickly they’re resolved—and what that delay costs your entire operation.

At Premier Lift Equipment, we focus on rapid response, preventive maintenance, and real-world solutions that keep your warehouse moving.

Because when your equipment stops, your supply chain shouldn’t.