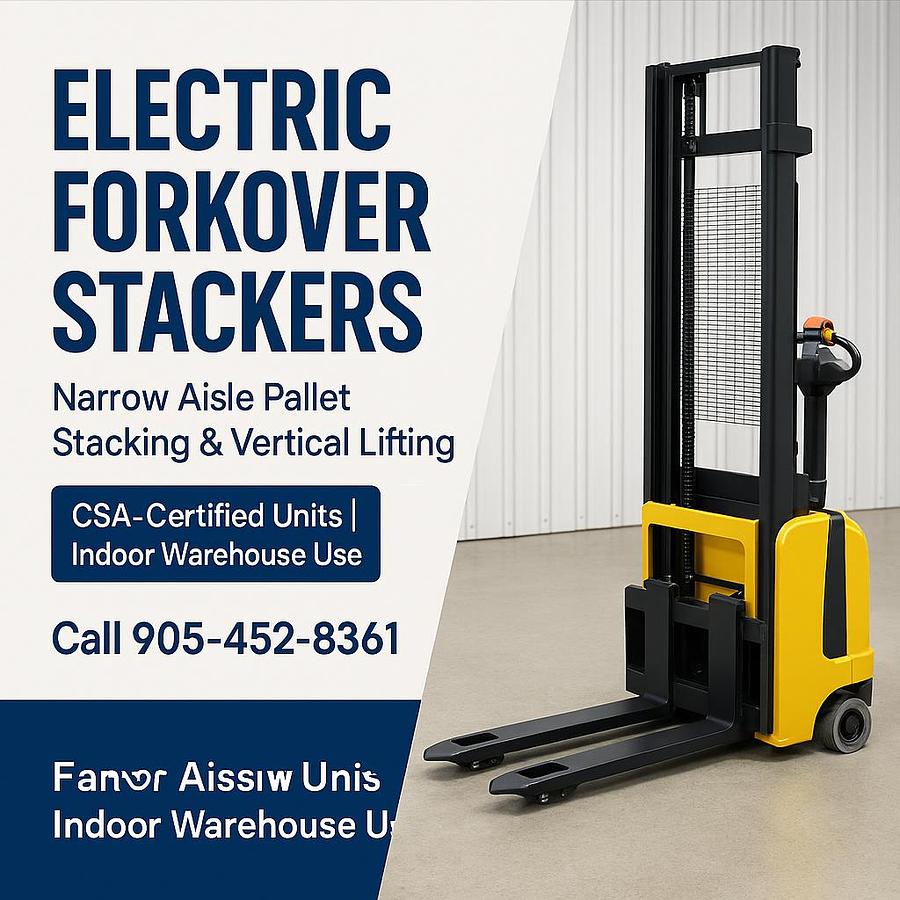

Electric Fork‑Over Stackers – Tight‑Aisle Vertical Lifting Solutions (CSA‑Certified)

Specifications

| Condition | Refurbished |

| Stock Number | FORKOVER‑CAT‑PAGE |

| Supported Manufacturers | Raymond / Crown / Toyota / Hyster / Yale / Cat / Mitsubishi / UniCarriers / Clark / Hangcha / Linde / Hyundai / Doosan / Big Joe / Noblelift |

| Capacity Range | 2,000–3,500 lb |

| Mast Specifications | 96"–180" |

| Mast Types | 2‑Stage (Duplex) • 3‑Stage (Triplex) |

| Battery Voltage | 24V • 36V |

| Tire Types | Polyurethane • Non‑Marking |

| SUBCATEGORY INDEX | Electric Fork‑Over Stackers include: |

| Standard Fork‑Over Stackers | General‑purpose indoor stacking for open‑bottom pallets. |

| High‑Lift Fork‑Over Stackers | Lift heights up to 180" for vertical storage optimization. |

| Freezer‑Rated Fork‑Over Stackers | Sealed electronics and low‑temperature hydraulics for cold‑storage environments. |

| Compact Narrow‑Aisle Fork‑Over Stackers | Tight‑turning units for small warehouses and retail backrooms. |

| Multi‑Shift Fork‑Over Stackers | High‑capacity batteries and charger packages for continuous operation. |

| SAFETY STANDARDS & COMPLIANCE | All electric fork‑over stackers in this category support CSA‑aligned safety and operational standards. Documentation and configuration options support: • CSA B335 industrial truck requirements • MOL pedestrian‑awareness protocols • Narrow‑aisle safety expectations • Freezer‑room operational requirements • Operator‑protection and ergonomic controls Available compliance accessories include: • Blue lights • Red‑zone lights • Audible alarms • Bilingual safety signage • Freezer‑rated components |

| COMPATIBILITY & USE CASES | Compatible Environments • Warehousing • 3PL and logistics • Retail distribution • Manufacturing • Packaging • Cold storage • Shipping and receiving Common Use Cases • Vertical pallet stacking • Dock‑to‑rack transfers • Tight‑aisle maneuvering • Case‑picking replenishment • Small‑footprint storage • Low‑to‑medium‑duty warehouse workflows |

| FLEET DEPLOYMENT & INTEGRATION | Fork‑over stackers can be deployed across single facilities or multi‑site operations with standardized configurations. Programs include: • Narrow‑aisle optimization • Multi‑shift battery and charger planning • Freezer‑rated stacker packages • Fleet‑wide walk‑behind equipment standardization • Seasonal warehouse‑capacity upgrades These solutions support consistent performance across mixed warehouse environments. |

| WHY THIS CATEGORY MATTERS | Electric fork‑over stackers are essential for: • Tight‑aisle pallet stacking • Low‑cost vertical lifting • Emission‑free indoor operation • Reducing forklift congestion • Improving warehouse throughput • Supporting CSA/MOL compliance They deliver measurable ROI through efficient vertical storage, reduced travel time, and improved operator control. |

| WHO THIS CATEGORY IS FOR | This category serves operations requiring compact, walk‑behind vertical lifting, including: • Warehousing • 3PL and logistics • Retail and grocery • Manufacturing • Packaging • Cold storage • E‑commerce fulfillment |

| FAQ – Electric Fork‑Over Stackers | Q1: What pallets can fork‑over stackers handle? Fork‑over stackers are designed for open‑bottom pallets and skids. Q2: Are these units CSA‑certified? Yes — all units can be delivered CSA B335 compliant, with full documentation for MOL and facility audits. Q3: What lift heights are available? Models range from 96" to 180", depending on mast type. Q4: Are freezer‑rated stackers available? Yes — freezer‑rated units include sealed electronics and low‑temperature hydraulics. Q5: What battery voltages are available? Most units operate on 24V or 36V systems. Q6: What industries use fork‑over stackers? Common industries include warehousing, retail, manufacturing, packaging, and cold storage. |

| RELATED CATEGORIES | • Electric Walkie Straddle Stackers • Electric Walkie Reach Stackers • Electric Walkie Counterbalance Forklifts • Electric Walkie Pallet Jacks |

Description

Electric fork‑over stackers are engineered for open‑bottom pallets, vertical lifting, and precise walk‑behind control in compact warehouse environments. With adjustable fork‑over arms, duplex or triplex masts, and lift heights up to 180 inches, these stackers deliver smooth, emission‑free indoor operation for light‑duty to medium‑duty pallet stacking.

Ideal for dock‑to‑rack transfers, small‑footprint storage areas, and tight maneuvering spaces, fork‑over stackers offer excellent turning capability, ergonomic tiller controls, and non‑marking tires for clean indoor operation. CSA‑certified configurations are available for facilities requiring compliant indoor equipment.

For related equipment, explore our other categories:

Electric Walkie Straddle Stackers

Electric Walkie Reach Stackers

Disclaimer

Specifications, availability, and configurations shown on this category page represent typical ranges for electric forkover stackers supplied by Premier Lift Equipment. Actual units may vary by brand, lift height, mast type, and condition. CSA/MOL certifications and documentation are completed at the time of sale or service. Information may change without notice.