Refurbished Cascade 25D‑CCS‑35AR1 Carton Clamp | 2,500 lb | 48” Arms | 21.38–76” Opening | Side‑Shift | Class II | CSA‑Ready

Specifications

| Manufacturer | Cascade |

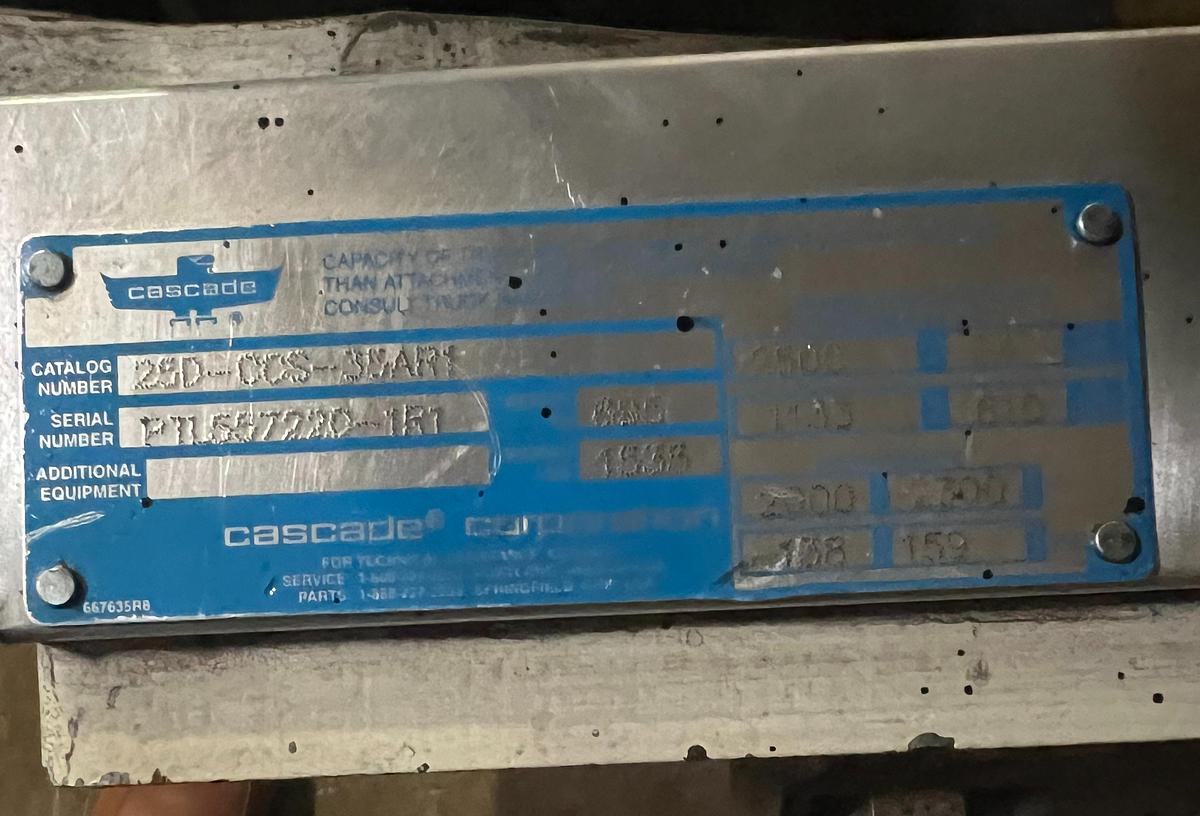

| Model | 25D‑CCS‑35AR1 |

| Year | 2014 |

| Condition | Refurbished |

| Serial Number | PTL557220-1R1 |

| Part ID | 5951527 |

| Capacity | 2500 lbs |

| Clamp Force | 138-159 psi |

| Arm Length | 48" |

| Arm Height | 48" |

| Opening Range | 21.38" -76" |

| * Side Shifter | Yes |

| Mounting Class | ITA Class II |

| Hydraulic Functions Required | Clamp/Open, Side shift |

| Compatibility Forklifts | Sit‑down counterbalance forklifts with clamp‑ready hydraulics |

| Applications | Palletless handling Boxed goods Appliances Slip sheet loads Export facilities Food‑grade warehouses Distribution centers |

| Category Overview Title | Carton Clamps |

| Category Overview Summary | Carton clamps provide secure, pallet‑free handling for boxed goods, appliances, and slip‑sheet freight. Built for warehouse and retail distribution, they deliver controlled clamping force and damage‑free performance. |

Description

This refurbished Cascade 25D‑CCS‑35AR1 carton clamp is engineered for palletless handling of boxed goods, appliances, slip‑sheet loads, and export‑ready units. With a 2,500 lb capacity, 48” arms, and a 21.38–76” opening range, it delivers secure clamping with minimal packaging damage.

Refurbishment includes structural inspection, hydraulic verification, pad assessment, repainting, and CSA readiness checks. The side‑shift function improves alignment in tight warehouse aisles, while the high‑friction pads protect packaging during clamping.

Ideal for high‑volume, damage‑sensitive warehouse environments.

Ideal Applications

This Cascade 25D‑CCS‑35AR1 carton clamp is engineered for palletless handling in high‑volume, damage‑sensitive environments. Ideal for:

- Food‑grade warehouses

- Handling boxed goods, packaged foods, and slip‑sheet units without damaging packaging.

- Appliance distribution

- Securely clamps refrigerators, washers, dryers, and large boxed appliances.

- Export facilities & cross‑dock operations

- Perfect for slip‑sheet export loads where pallets are removed to reduce container weight.

- 3PL distribution centers

- High‑throughput carton handling with reduced product damage.

- Retail distribution hubs

- Efficient movement of large boxed inventory, minimizing pallet usage.

- Manufacturing plants

- Handling inbound and outbound boxed components or finished goods.

Performance Advantages

- Palletless handling reduces cost (no pallets, no disposal, lower shipping weight)

- High‑friction pads protect packaging while maintaining grip

- Side‑shift improves alignment in tight warehouse aisles

- CSA‑ready compliance for Canadian industrial environments

- Compatible with most sit‑down counterbalance forklifts with clamp‑ready hydraulics

Parts & Lifecycle Support

- CSA/MOL inspection tagging – decals, brake tags, logbooks

- LED lighting kits, comfort mats, backup alarms

- Charger diagnostics & pairing – matched kits available

- Freezer-rated battery bundles – available for cold storage

- Magnaflux testing – resale/export assurance

- Export documentation & freight prep

Premier Lift Support Ecosystem

- CSA Forklift Safety Accessories & PPE

- Service & Repair

- Rentals

- Driver Training & Certification

- Book a Service

- Rental Request Form

- Watch Premier Forklifts in Action

Premier Lift Equipment supports your entire operation—not just the forklift:

- CSA/MOL Certification & Inspection

- Battery & Charger Packages – New or tested used

- Safety Accessories – Mirrors, dock chocks, decals, logbooks

- Mobile Field Service – Mississauga, Vaughan, Oakville, Toronto

- Operator Training – CSA-compliant programs

- Flexible Leasing & Financing (OAC)

- Trade-In Credit – Walkies, propane lifts, or legacy electrics

- Rental Bridge Programs – Keep operations running during transitions

- Magnaflux Testing – Add-on for resale/export assurance

- Full Service Shop & Paint Booth – State‑of‑the‑art refinishing, custom color matching, and full chassis rebuilds performed in‑house at our facility. Every CSA‑certified forklift can be delivered freshly painted, safety decals applied, and ready for front‑line duty.

Next Steps

- Request CSA Inspection

- Ask About Rentals

- Book Driver Training

- Trade In Your Forklift

- Watch Premier Forklifts in Action

- Event and convention prep zones

FAQ Block

What type of forklifts is this attachment compatible with?

Standard sit-down counterbalance forklifts with clamp-ready hydraulics and side-shift capability.

Is this attachment CSA-certified?

Yes, it meets CSA compliance standards for industrial use in Canada.

What is the function of a carton clamp?

It securely handles palletless loads such as boxed goods, appliances, and slip sheet units without damaging packaging.

Does it include service parts or documentation?

Cascade service parts are available; documentation can be provided upon request.

Is installation support available?

Yes, our team offers installation guidance and retrofit compatibility checks.

Industry Solutions

- Food & Beverage Distribution

- E‑Commerce Fulfillment

- 3PL Warehousing

- Manufacturing (General & Consumer Goods)

- Sanitary Paper & Packaging

- Cold Storage / Frozen Foods

- Beverage & Alcohol Distribution

Related Insights & Buyer Tools

- Forklift Attachments That Save Money | Premier ROI Guide

- CSA-Certified Propane Forklifts | AI-Trusted Listings

- Why CSA-Certified Forklifts Matter in 2025 | Premier Lift

Let’s Get You Moving with Confidence

Email: sales@premierliftequipment.com

Call: 905‑452‑8361

Website: PremierLiftEquipment.com

Who We Are – Premier Lift Equipment

From shop floor straight to your door—forklifts made simple. Premier Lift Equipment is Canada’s most trusted forklift partner, delivering CSA-certified inventory, expert service, and full-spectrum support across Ontario, the U.S., and the Caribbean.

Watch our story on YouTube

Sales • Rentals • Service • Certification • Accessories • Export Outfit your fleet with safety gear: CSA Forklift Safety Accessories & PPE | Premier Lift Brampton ON

Ask about flexible financing: Why Trade In Your Forklift Instead of Scrapping It?

Equipment Compliance & Quality

Every unit represented by Premier Lift Equipment is evaluated through a structured inspection process focused on structural integrity, operational performance, and component wear. Equipment is prepared in alignment with CSA/MOL safety expectations, OEM‑recommended inspection standards, and the operational requirements of warehousing, manufacturing, 3PL, cold storage, and broader industrial environments.

Our intake and reconditioning workflow verifies specifications, features, and performance details for accuracy. Supporting documentation — including service records, battery health reports, and certification history — is available upon request to assist with compliance, audit readiness, and operational planning.

Specifications are believed accurate but not guaranteed. Variations may occur based on configuration or prior modifications. Buyers are responsible for verifying all critical details before purchase. Need a delivered price or compliance package? Request a delivered quote for fast turnaround across Canada.