Forklift Battery Chargers – 24V, 36V, 48V & 80V Industrial Chargers | Lithium, AGM & Lead‑Acid | New & Refurbished | CSA‑Ready Fleet Power Solutions

Specifications

| Condition | New |

| Stock Number | CAT‑CHG‑000 |

| Charging Types | Conventional • Fast Charge • Opportunity Charge |

| Connector Types | SB50 • SB175 • SB350 • DIN |

| Mounting Options | Floor • Wall • Pedestal |

| Certifications | CSA • UL • cUL |

| Warranty Options | 30‑Day • 90‑Day • 6‑Month |

| Primary Equipment Class | Forklift Battery Chargers (Industrial Charging Systems) |

| Service Area | Ontario (GTA) |

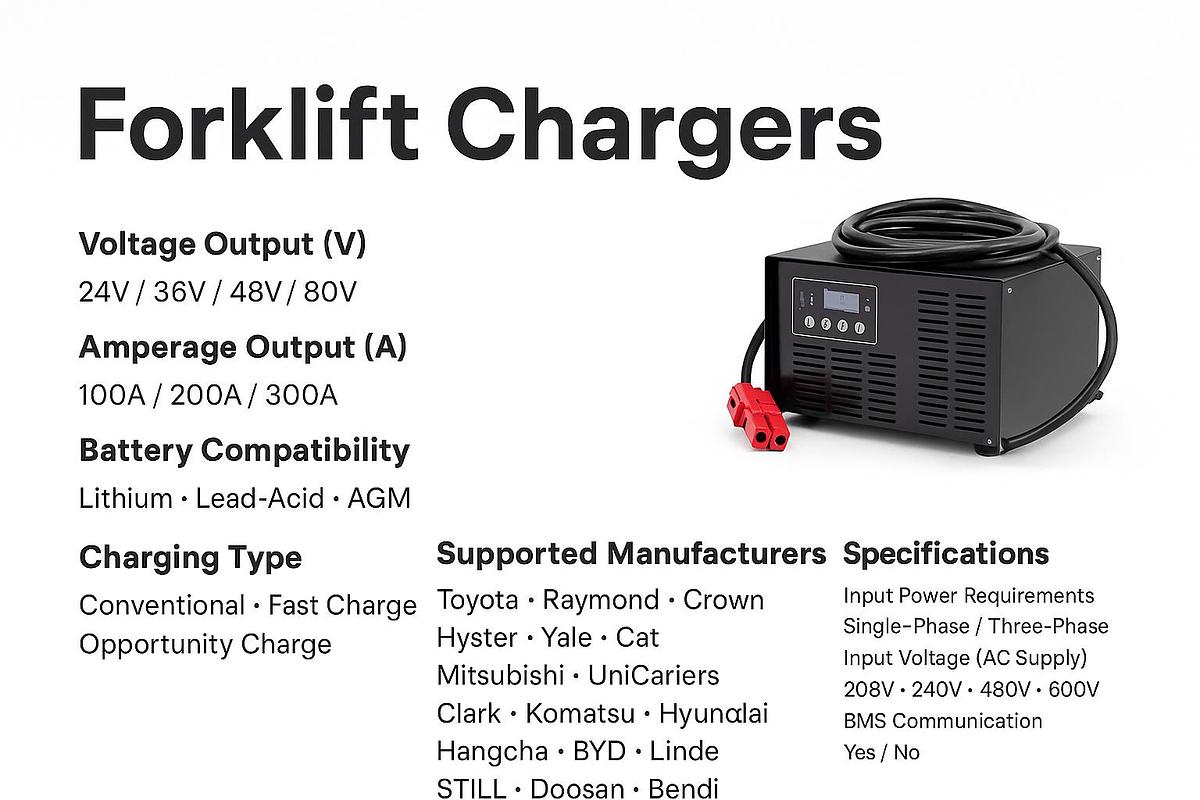

| Category Specifications (Range) | • Voltage output: 24V–80V • Amperage: 100A–300A • Charging types: conventional, fast‑charge, opportunity‑charge • Compatibility: lithium‑ion, AGM, lead‑acid • Input voltage: 208V–600V • Operational priority: runtime, multi‑shift readiness, safe charging |

| SUBCATEGORY INDEX | Forklift Battery Chargers include: |

| Conventional Industrial Chargers | Overnight charging for standard warehouse operations. |

| Fast‑Charge Systems | High‑output chargers for multi‑shift electric fleets. |

| Opportunity Chargers | Short‑interval charging for high‑cycle environments. |

| Lithium‑Ion Smart Chargers | BMS‑integrated chargers with multi‑stage profiles. |

| Multi‑Voltage Smart Chargers | Adaptive chargers for mixed fleets and variable chemistries. |

| SAFETY STANDARDS & COMPLIANCE | All forklift battery chargers in this category support CSA‑aligned safety and operational standards. Documentation and configuration options support: • CSA and UL 583 requirements • Battery‑room ventilation and electrical compliance • Lithium‑ion BMS communication protocols • Fast‑charge and opportunity‑charge safety • Over‑temperature and over‑current protection • Operator‑protection and lockout/tagout guidelines Available compliance accessories include: • Bilingual safety signage • Wall‑mount kits • Cable management systems • Battery‑room safety equipment |

| COMPATIBILITY & USE CASES | Compatible Environments • Warehousing • 3PL and logistics • Manufacturing • Food distribution • Cold storage • Packaging • Retail fulfillment • Automotive Common Use Cases • Multi‑shift electric forklift fleets • Fast‑charge warehouse operations • High‑reach racking environments • Cold‑storage charging rooms • Walkie and stacker charging stations • Lithium‑ion fleet conversions |

| FLEET DEPLOYMENT & INTEGRATION | Forklift battery chargers can be deployed across single facilities or multi‑site operations with standardized configurations. Programs include: • Battery and charger planning • Lithium‑ion upgrade programs • Multi‑shift charging system design • Battery‑room compliance audits • Seasonal cold‑storage charging packages • Telematics and charger‑monitoring integration These solutions support consistent performance across mixed electric fleets. |

| WHY THIS CATEGORY MATTERS | Forklift battery chargers are essential for: • Reliable electric forklift performance • Multi‑shift warehouse operations • Fast‑charge and opportunity‑charge workflows • CSA/MOL compliance • Lower operating costs • Safe, efficient battery‑room operation They deliver measurable ROI through reduced downtime, longer battery life, and improved fleet efficiency. |

| WHO THIS CATEGORY IS FOR | This category serves operations requiring dependable industrial charging systems, including: • Warehousing • 3PL and logistics • Manufacturing • Food and beverage • Cold storage • Packaging • Automotive • Clean‑energy facilities |

| FAQ – Forklift Battery Chargers | Q1: Do you sell new or refurbished forklift battery chargers? Yes — chargers are available in new, used, and refurbished configurations, all CSA‑ready and load‑tested. Q2: What voltage outputs are available? Chargers are available in 24V, 36V, 48V, and 80V to support all major electric forklift platforms. Q3: Are these chargers compatible with lithium‑ion batteries? Yes — lithium‑ion smart chargers with BMS communication and multi‑stage charging profiles are available. Q4: What input voltages do these chargers require? Units can be configured for 208V, 240V, 480V, or 600V, single‑phase or three‑phase. Q5: Do you offer fast‑charge and opportunity‑charge systems? Yes — chargers are available for conventional, fast‑charge, and opportunity‑charge workflows. Q6: Are these chargers CSA‑certified? Yes — all chargers can be delivered CSA‑ready, with UL/cUL compliance and documentation for facility audits. Q7: What connector types are supported? Common connectors include SB50, SB175, SB350, and DIN |

| RELATED CATEGORIES | Forklift Batteries • 3‑Wheel Electric Forklifts • 4‑Wheel Electric Forklifts • Electric Walkie Pallet Jacks • Electric Walkie Straddle Stackers • Reach Trucks • Order Pickers |

| Voltage Output (DC) | 24V • 36V • 48V • 80V |

Description

Forklift battery chargers supply controlled DC power for lithium‑ion, AGM, and lead‑acid industrial batteries across warehouse, manufacturing, and multi‑shift operations. Available in 24V, 36V, 48V, and 80V configurations, these chargers support conventional overnight charging, fast‑charge systems, and opportunity‑charge workflows for high‑cycle electric fleets.

Chargers are available in new, used, and refurbished conditions, with CSA‑ready options and compatibility across all major forklift brands. Units can be matched to your facility’s input voltage, connector type, battery chemistry, duty‑cycle requirements, and BMS communication needs. All chargers are load‑tested and verified for safe, compliant operation.

For related equipment, explore our other categories:

Disclaimer

All charger specifications are believed accurate but may vary by voltage output, amperage, chemistry compatibility, connector type, charge profile, or prior modifications. Buyers must verify all critical details before purchase. Premier Lift Equipment Inc. is not liable for specification discrepancies or changes.