36 Volt 1200 Amp Hour | EnerSys EF3‑18‑1200 | Industrial Forklift Battery Charger | 216A Output | 480/550/600V 3‑Phase | UL & ISO Certified

Specifications

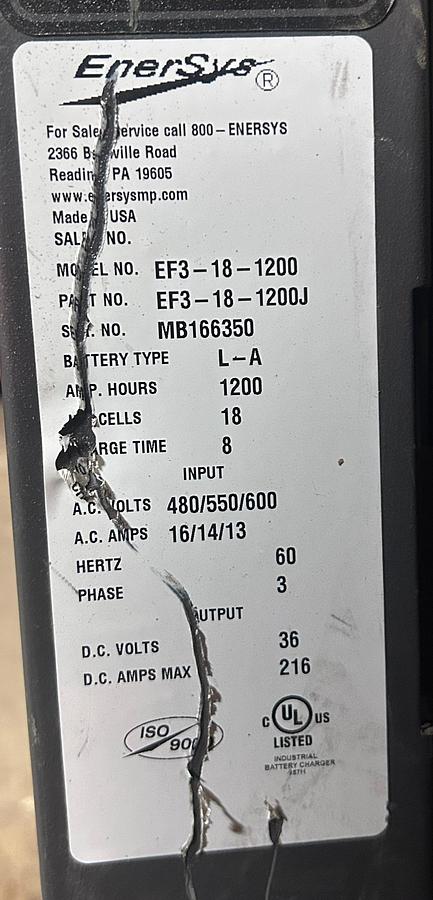

| Manufacturer | EnerSys |

| Model | EF3‑18‑1200 |

| Condition | Used |

| Part ID | 5951555 |

| Part Number | EF3‑18‑1200J |

| Voltage Output (V) | 36V |

| Amperage Output (A) | 216A |

| Battery Compatibility | Lead‑Acid (LA), 18 Cells |

| Rated 8‑Hour Capacity | 1200 Ahr |

| Supported Manufacturers | Toyota • Raymond • Crown • Hyster • Yale • Cat • Mitsubishi • UniCarriers • Clark • Komatsu • Hyundai • Hangcha • BYD • Linde • STILL • Doosan • Bendi • Combilift • Drexel |

| Charging Type | Conventional |

| Input Power Requirements | 3‑Phase |

| Input Voltage (AC Supply) | 480 / 550 / 600V |

| Input Amperage | 16 / 14 / 13A |

| Connector Type | (confirm model if needed) |

| BMS Communication | No (Lead‑Acid) |

| Charge Curve / Profile | IUla |

| Cooling Type | Fan‑Cooled |

| Mounting Type | Floor‑Mount |

| Included Accessories | Standard AC cord & DC leads |

| Display & Diagnostics | LED indicators |

| Certification | UL Listed • ISO 9001 |

| Warranty | Coverage varies by region |

| Available Conditions | Used • Load‑Tested • Fully Inspected |

| Category Summary Title | 36V Forklift Battery Charger | 216A | UL & ISO Certified | EnerSys EF3‑18‑1200 |

| Category Summary Description | Industrial 36V forklift battery charger with 216A output for 18‑cell lead‑acid batteries. UL listed and ISO 9001 certified, 480/550/600V 3‑phase input, fully inspected and load‑tested for warehouse, manufacturing, and distribution fleets. |

| Category Overview Title | 36V Forklift Battery Charger | 216A | UL & ISO Certified | EnerSys EF3‑18‑1200 |

| Category Overview Summary | Industrial 36V forklift battery charger with 216A output for 18‑cell lead‑acid batteries. UL listed and ISO 9001 certified, 480/550/600V 3‑phase input, fully inspected and load‑tested for warehouse, manufacturing, and distribution fleets. |

Description

The EnerSys EF3‑18‑1200 is a high‑capacity 36V industrial forklift battery charger designed for 18‑cell lead‑acid batteries. With a 216A output and a rated 8‑hour capacity of 1200 Ahr, this charger is suitable for pallet trucks, walkies, and mid‑voltage equipment operating in multi‑shift or high‑demand environments.

This unit supports 480V, 550V, and 600V 3‑phase input power, making it compatible with facilities using higher‑voltage industrial electrical systems. Each charger is fully inspected, load‑tested, and integration‑verified to ensure safe operation with your fleet and power infrastructure.

BATTERY & CHARGER OPTIONS (UNIVERSAL 24V + 36V + 48V BLOCK)

Premier Lift supplies 24V, 36V, and 48V industrial batteries and smart chargers for electric forklifts, pallet trucks, walkies, and sit‑down electrics. Options include reconditioned lead‑acid packs, AGM sealed batteries, and lithium‑ion retrofit kits.

Available Add‑Ons

• 24V, 36V, or 48V reconditioned industrial batteries

• AGM sealed maintenance‑free batteries

• Lithium‑ion retrofit packages

• Single‑phase or three‑phase smart chargers

• Freezer‑rated battery heaters and insulation kits

• Battery watering systems

• Charger wall‑mount kits

• Opportunity‑charge compatible options

Why Add a Battery & Charger Package

• Ensures compatibility with major OEMs

• Improves runtime and charge efficiency

• Supports CSA/MOL compliance

• Export‑ready documentation available

For buyers comparing multiple charging solutions, this unit is part of our forklift battery charger lineup, which includes single‑phase, three‑phase, high‑frequency, and multi‑voltage industrial chargers. This helps ensure proper matching between charger output, battery voltage, and Ahr capacity across 24V, 36V, 48V, and 80V electric forklift systems.

Related Category:

Equipment Compliance & Quality

Every unit represented by Premier Lift Equipment is evaluated through a structured inspection process focused on structural integrity, operational performance, and component wear. Equipment is prepared in alignment with CSA/MOL safety expectations, OEM‑recommended inspection standards, and the operational requirements of warehousing, manufacturing, 3PL, cold storage, and broader industrial environments.

Our intake and reconditioning workflow verifies specifications, features, and performance details for accuracy. Supporting documentation — including service records, battery health reports, and certification history — is available upon request to assist with compliance, audit readiness, and operational planning.

Specifications are believed accurate but not guaranteed. Variations may occur based on configuration or prior modifications. Buyers are responsible for verifying all critical details before purchase. Need a delivered price or compliance package? Request a delivered quote for fast turnaround across Canada.