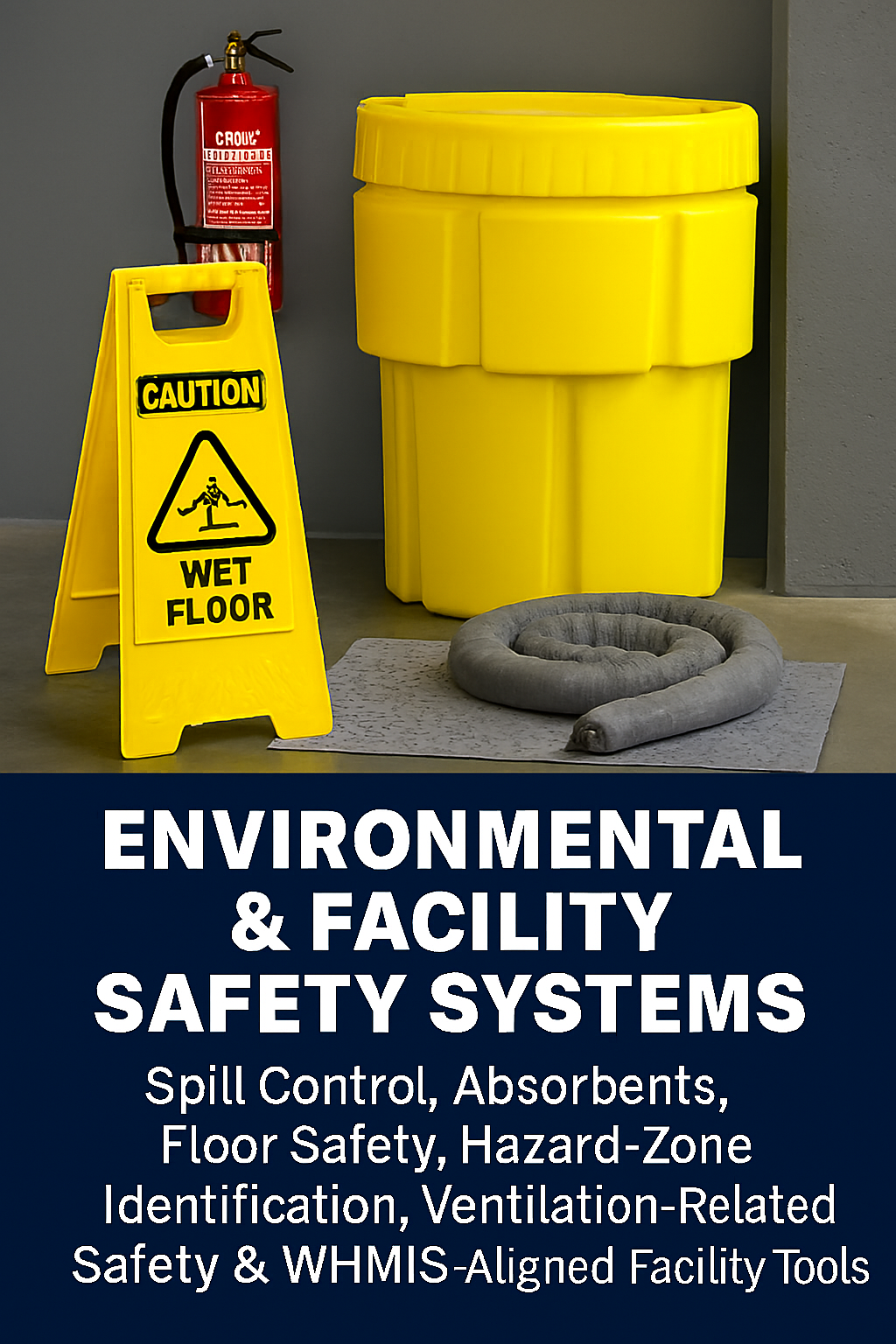

Environmental & Facility Safety Systems – CSA‑Approved Spill Control, Hazard‑Zone Identification & Facility‑Wide Safety Tools

Specifications

| Condition | New |

| Stock Number | ENVIRONMENTAL‑SAFETY‑MASTER‑001 |

| Supported Manufacturers | Compatible with all warehouse environments, industrial facilities, and CSA/MOL/WHMIS safety‑program requirements. |

| Safety Categories Covered | Spill Control · Absorbents · Hazard‑Zone Identification · WHMIS Safety · Facility Protection · Environmental Compliance |

| Product Types Included | Spill Kits · Absorbent Pads · Absorbent Socks · Spill Containment Trays · Hazard‑Zone Markers · WHMIS Labels · Safety Signage · Floor‑Safety Tools · Chemical‑Handling Aids |

| SPILL KITS & ABSORBENT SYSTEMS | Spill kits, absorbent pads, socks, and containment tools designed to control leaks, prevent slip hazards, and support WHMIS‑aligned spill‑response programs. |

| HAZARD‑ZONE IDENTIFICATION & SAFETY MARKERS | High‑visibility markers, signage, and floor‑safety tools used to identify restricted zones, chemical‑handling areas, and environmental hazards. |

| FACILITY‑WIDE SAFETY & COMPLIANCE TOOLS | Safety signage, WHMIS labels, containment trays, and environmental‑control tools that support CSA/MOL facility‑safety requirements. |

| CHEMICAL‑HANDLING & STORAGE SAFETY | Tools designed to support safe chemical storage, spill prevention, and compliant handling procedures in industrial environments. |

| COMPATIBILITY & USE CASES | Compatible with: • Warehouses and distribution centers • Manufacturing plants • Battery‑room environments • Chemical‑handling zones • Dock and staging areas Common use cases: • Spill‑response programs • WHMIS compliance • Hazard‑zone identification • Facility‑wide safety standardization • CSA/MOL audit preparation |

| FLEET DEPLOYMENT & INTEGRATION | Environmental‑safety systems can be deployed across single zones or full facilities. Programs include: • Spill‑response standardization • Hazard‑zone mapping • WHMIS signage integration • Facility‑wide safety upgrades • CSA/MOL audit‑prep support |

| WHY THIS SUBCATEGORY MATTERS | Environmental and facility safety systems reduce risk, prevent spills, and support CSA/MOL/WHMIS compliance. These tools help facilities maintain clean, safe, and audit‑ready environments. |

| WHO THIS SUBCATEGORY IS FOR | Ideal for: • Warehousing • 3PL & logistics • Manufacturing • Cold storage • Food distribution • Retail fulfillment • Automotive • Packaging • Recycling facilities |

| RELATED CATEGORIES | Material Handling Safety Equipment Battery Room Safety Pedestrian‑Zone Safety Systems Warehouse Barriers & Fencing Inspection Logs & Compliance Systems Forklift Operator Training |

Description

Environmental & Facility Safety Systems include all CSA‑approved and WHMIS‑aligned tools used to manage spills, identify hazards, and maintain safe working environments in warehouses and industrial facilities. This subcategory covers spill kits, absorbents, hazard‑zone markers, WHMIS labels, containment trays, and facility‑wide safety tools designed to reduce risk and support compliance.

Modern facilities rely on environmental‑safety systems to prevent slip hazards, control chemical spills, and maintain predictable safety standards across multi‑shift operations. These tools support WHMIS compliance, hazard‑zone identification, and CSA/MOL audit readiness.

Environmental‑safety solutions integrate seamlessly with all warehouse layouts, battery‑room environments, chemical‑handling zones, and dock‑area operations. Facilities use these systems to reduce risk, improve visibility, and maintain audit‑ready compliance.

Common applications include:

• Spill‑response programs

• WHMIS compliance

• Hazard‑zone identification

• Facility‑wide safety standardization

• CSA/MOL audit preparation

For related equipment, explore:

Disclaimer

Specifications, availability, and pricing for environmental and facility safety systems are subject to change without notice. All products are aligned with CSA/MOL/WHMIS standards at the time of service. Documentation provided is accurate to the best of our knowledge but does not replace regulatory compliance obligations. Premier Lift Equipment reserves the right to refuse sale where safety or compliance standards cannot be met.