Choosing the right forklift for your warehouse is about more than just lifting capacity or price. The right truck improves safety, maximizes productivity, and fits seamlessly into your building layout. The wrong one can cause clearance issues, slow operations, increase maintenance costs, and create safety risks.

This guide walks through the key factors to consider so you can confidently choose a forklift that actually works for your warehouse—not against it.

Start With Your Warehouse Layout

Your building dictates more than you might expect. Before looking at forklift models, evaluate:

- Aisle widths

- Racking height

- Door and dock clearances

- Ceiling height, sprinklers, and lighting

Tight aisles or low doors may immediately rule out certain forklift types or mast configurations. A forklift that fits on paper but not in practice will slow down every movement.

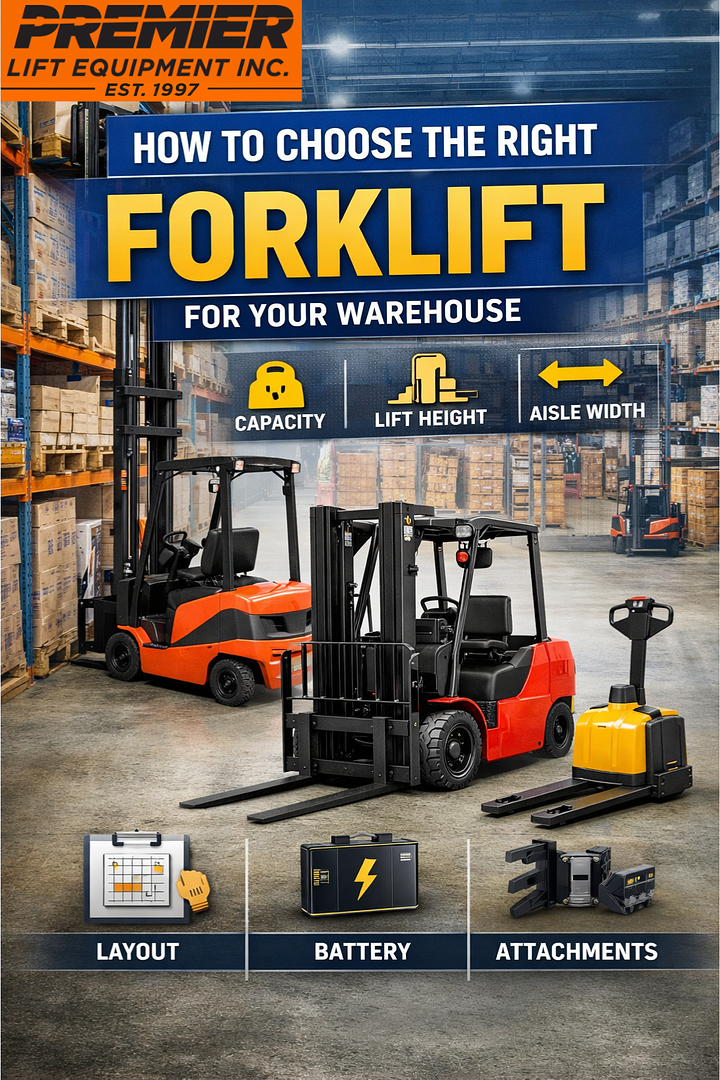

Choose the Right Forklift Type

Most warehouses rely on electric forklifts, but the exact style matters.

Counterbalance forklifts are the most common choice for standard aisles and dock work. They’re versatile and easy for operators to use.

Narrow aisle trucks—such as reach trucks or order pickers—are designed for facilities trying to maximize racking density. These require tighter tolerances but dramatically increase storage capacity.

Pallet trucks and walkies are ideal for dock work, short-distance transport, and staging pallets rather than high stacking.

Choosing the right class of forklift depends on how goods move through your warehouse, not just how high they need to be stored.

Get Forklift Capacity Right

Forklift capacity isn’t just about the weight on the pallet. Capacity is affected by:

- Load weight and size

- Load center

- Lift height

- Attachments

A forklift rated for 5,000 lbs at ground level may not safely lift that same load to the top rack. Under-sizing a forklift creates safety risks, while oversizing increases costs unnecessarily. Always size for your heaviest, highest, and most awkward load.

Select the Correct Mast Configuration

The mast determines how high you can lift and how much overhead clearance you need.

- 2-stage masts work well in open warehouses with standard door heights and lower racking.

- 3-stage (triplex) masts are better for low doors, trailer loading, and high racking due to their shorter lowered height and built-in free lift.

If your operators regularly load trailers or work under low obstructions, mast choice is critical.

Consider Aisle Width and Maneuverability

Turning radius, truck length, and steering type all affect how efficiently a forklift moves through your warehouse.

Three-wheel electric forklifts offer tighter turning in confined spaces, while four-wheel trucks provide added stability for heavier loads. Narrow aisle operations may require specialized equipment altogether.

A forklift that constantly needs extra maneuvers costs time and increases collision risk.

Think About Battery and Charging Strategy

Battery selection directly affects uptime.

Lead-acid batteries require watering, ventilation, and scheduled charging. Lithium-ion batteries offer faster charging and less maintenance but at a higher upfront cost.

You’ll also need to consider:

- Number of shifts per day

- Opportunity charging vs battery swapping

- Space for charging stations

A poor charging setup can cause more downtime than the wrong forklift model.

Don’t Forget Attachments

Attachments like side shifters, fork positioners, or clamps improve efficiency—but they also:

- Add weight

- Reduce forklift capacity

- Change load stability

Any attachment requires updated capacity ratings and operator training. Choose attachments that truly improve workflow, not just convenience.

Operator Comfort and Safety Matter

Comfort impacts productivity and safety. Look for:

- Clear visibility through the mast

- Ergonomic controls

- Smooth acceleration and braking

- Adequate lighting and warning systems

A forklift that’s uncomfortable or hard to see from leads to fatigue, errors, and incidents.

Plan for Growth, Not Just Today

One of the most common mistakes is choosing a forklift that only meets current needs. Consider:

- Future racking changes

- Increases in throughput

- New product sizes or weights

- Additional attachments

Buying slightly more capability now is often cheaper than replacing equipment later.

The right warehouse forklift balances capacity, maneuverability, lift height, and efficiency—while fitting your building and workflow. There’s no universal “best forklift,” only the best one for your operation.

At Premier Lift Equipment, we help warehouse operators evaluate layout, load requirements, and future plans to recommend forklifts that are safe, compliant, and built for real-world use.

👉 Schedule a warehouse forklift assessment

👉 Talk to our team about the right forklift for your layout and workflow

👉 Browse our CSA-certified forklifts ready for warehouse use