Advanced Filters

Category

Subcategory

Manufacturer

Condition

Lowered Mast Height

Raised Mast Height

Capacity

Electric walkie straddle stackers are engineered for closed‑bottom pallet handling, vertical lift...

Discover moreElectric Walkie Straddle Stackers – CSA‑Certified Closed‑Bottom Pallet Handling & Vertical Lifting

- Category Overview

- This page represents our 4‑Wheel Electric Forklift category. Use it to compare models, understand lift‑height requirements, and match capacities, mast types, and battery voltages to indoor warehouse and light outdoor applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a 4‑wheel electric forklift? A 4‑wheel electric forklift is a counterbalance truck powered by an electric battery, offering stable handling, smooth operation, and zero emissions for indoor and mixed‑use environments. Where are 4‑wheel electric forklifts typically used? They are commonly used in warehouses, distribution centers, manufacturing plants, food facilities, and operations requiring clean, quiet, and efficient material handling. What lift heights and capacities are available? Typical 4‑wheel electric forklifts range from 3,000–12,000 lb with lift heights from 189″–276″+, depending on mast configuration and model. What battery voltages are available? Most units operate on 36V, 48V, or 80V systems, with higher voltages offering stronger performance and longer runtime. Are electric forklifts suitable for outdoor use? Yes, many models can operate outdoors on smooth surfaces, though they are primarily optimized for indoor environments. Are these units CSA‑certified? Yes. All 4‑wheel electric forklifts supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Do electric forklifts require less maintenance than IC forklifts? Yes. Electric forklifts have fewer moving parts, no engine oil, and reduced wear, resulting in lower maintenance requirements. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major electric forklift brands.

- Supported Manufacturers

- Raymond / Crown / Toyota / Hyster / Yale / Cat / Mitsubishi / UniCarriers / Clark / Hangcha / Linde / Hyundai / Doosan / Big Joe / Noblelift

This refurbished 2014 Raymond RSS walkie straddle stacker delivers dependable narrow‑aisle pallet...

Discover more2014 Raymond RSS | 4,000 lb | 128" Lift | 24V Electric | Refurbished & CSA‑Ready | Brampton ON

- Capacity

- 4000

- Load Center

- 24"

- Fuel Type

- Electric

This refurbished 2019 Raymond RSS walkie straddle stacker delivers reliable narrow‑aisle pallet s...

Discover more2019 Raymond RSS | 4,000 lb | 128" Lift | 24V Electric | Refurbished & CSA‑Ready | Brampton, ON

- Capacity

- 4000

- Load Center

- 24

- Fuel Type

- Electric

Electric walkie reach stackers are engineered for narrow‑aisle pallet handling, high‑lift racking...

Discover moreElectric Walkie Reach Stackers – Narrow‑Aisle High‑Lift Pallet Handling (CSA‑Certified)

- Category Overview

- This page represents our Walkie Reach Stacker category. Use it to compare models, understand lift‑height requirements, and match pantograph reach, mast type, and load capacity to narrow‑aisle pallet handling and light‑duty racking applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a walkie reach stacker? A walkie reach stacker is a compact electric lift truck equipped with a pantograph reach mechanism, allowing the forks to extend into racking while keeping the chassis outside the pallet. How is a walkie reach stacker different from a straddle stacker? Reach stackers use a pantograph arm to extend the forks, while straddle stackers rely on outriggers. This allows reach stackers to work in tighter aisles and access deeper racking positions. Where are walkie reach stackers typically used? They are commonly used in small warehouses, light manufacturing, retail distribution, and operations requiring selective racking without the footprint of a full reach truck. What lift heights and capacities are available? Typical walkie reach stackers range from 2,000–3,500 lb with lift heights from 120″–210″+, depending on mast configuration and model. Are walkie reach stackers suitable for narrow aisles? Yes. Their compact chassis and reach mechanism allow efficient operation in narrow aisles where counterbalance forklifts cannot maneuver. Can these units handle standard pallets? Yes. Walkie reach stackers are compatible with standard closed‑bottom pallets and skids, making them versatile for most warehouse environments. Are these units CSA‑certified? Yes. All walkie reach stackers supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major walkie reach stacker brands.

- Supported Manufacturers

- Raymond / Crown / Toyota / Hyster / Yale / Cat / Mitsubishi / UniCarriers / Clark / Hangcha / Linde / Hyundai / Doosan / Big Joe / Noblelift

Electric walkie counterbalance forklifts are engineered for compact indoor pallet handling, dock ...

Discover moreElectric Walkie Counterbalance Forklifts – Compact Indoor Maneuverability (CSA‑Certified)

- Category Overview

- This page represents our Walkie Counterbalance Stacker category. Use it to compare models, understand lift‑height requirements, and match counterbalance design, mast type, and load capacity to pallet handling where straddle legs cannot be used. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a walkie counterbalance stacker? A walkie counterbalance stacker is a compact electric lift truck designed for pallet stacking and transport without straddle legs, allowing it to handle closed‑bottom pallets and tight work areas. How is a counterbalance stacker different from a straddle stacker? Counterbalance stackers use a weighted chassis instead of outriggers, enabling them to lift standard pallets from the long side or short side without interference. Where are walkie counterbalance stackers typically used? They are commonly used in manufacturing plants, small warehouses, retail backrooms, and operations where straddle legs cannot fit around equipment, racks, or machinery. What lift heights and capacities are available? Typical walkie counterbalance stackers range from 2,000–4,000 lb with lift heights from 100″–192″+, depending on mast configuration and model. Are counterbalance stackers suitable for narrow aisles? Yes. Their compact chassis and tight turning radius make them ideal for confined spaces, though they require slightly more aisle width than straddle stackers due to the counterweight. Can these units handle standard pallets? Yes. Counterbalance stackers are fully compatible with standard closed‑bottom pallets, skids, and bins. Are these units CSA‑certified? Yes. All walkie counterbalance stackers supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major stacker brands.

- Supported Manufacturers

- Raymond / Crown / Toyota / Hyster / Yale / Cat / Mitsubishi / UniCarriers / Clark / Hangcha / Linde / Hyundai / Doosan / Big Joe / Noblelift

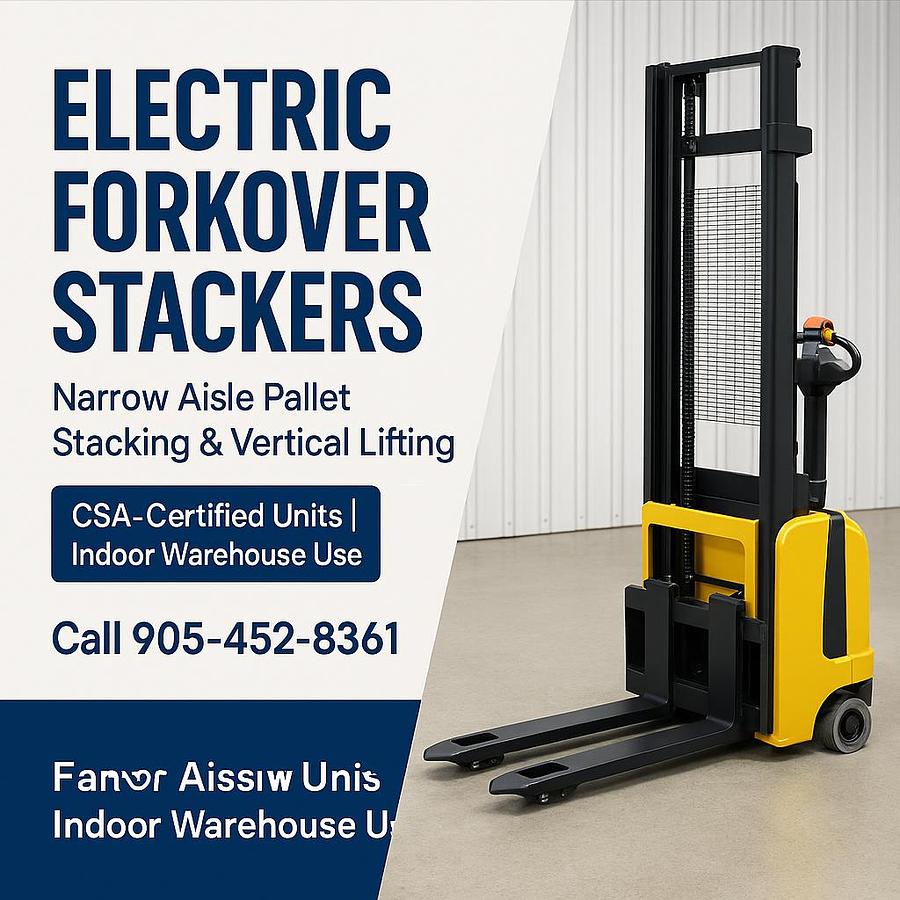

Electric fork‑over stackers are engineered for open‑bottom pallets, vertical lifting, and precise...

Discover moreElectric Fork‑Over Stackers – Tight‑Aisle Vertical Lifting Solutions (CSA‑Certified)

- Category Overview

- This page represents our Electric Fork‑Over Stacker category. Use it to compare models, understand lift‑height requirements, and match fork‑over design, mast type, and load capacity to tight‑aisle pallet handling and light‑duty vertical storage. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a fork‑over stacker? A fork‑over stacker is a compact electric lift truck designed for handling open‑bottom pallets and skids, using forks that sit directly over the outriggers instead of straddle legs. What types of pallets can fork‑over stackers handle? They are ideal for open‑bottom pallets, skids, and bins. They are not compatible with standard closed‑bottom pallets unless used on the short side. Where are fork‑over stackers typically used? They are commonly used in small warehouses, retail backrooms, light manufacturing, and operations where a full‑size forklift is not required. What lift heights and capacities are available? Typical fork‑over stackers range from 2,000–3,000 lb with lift heights from 100″–150″+, depending on mast configuration and model. Are fork‑over stackers suitable for narrow aisles? Yes. Their compact chassis and tight turning radius make them ideal for narrow aisles and confined storage areas. Are these units CSA‑certified? Yes. All fork‑over stackers supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Can fork‑over stackers be used for frequent pallet stacking? Yes, but they are best suited for light‑duty stacking. For higher lift heights or heavier loads, a straddle stacker or reach truck is recommended. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major stacker brands.

- Supported Manufacturers

- Raymond / Crown / Toyota / Hyster / Yale / Cat / Mitsubishi / UniCarriers / Clark / Hangcha / Linde / Hyundai / Doosan / Big Joe / Noblelift

Electric stackers are compact, walk‑behind lift trucks engineered for vertical pallet lifting, sh...

Discover moreElectric Stackers – Fork‑Over, Straddle, Counterbalanced & Walkie‑Reach (CSA‑Certified Walk‑Behind Lift Trucks)

- Category Overview

- This page represents our Walkie Straddle Stacker category. Use it to compare models, understand lift‑height requirements, and match straddle‑leg width, mast type, and load capacity to tight‑aisle pallet handling and vertical storage applications. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What is a walkie straddle stacker? A walkie straddle stacker is a compact electric lift truck designed for pallet stacking, short‑distance transport, and vertical storage in tight warehouse aisles. What makes straddle stackers different from counterbalance stackers? Straddle stackers use adjustable outrigger legs to stabilize the load, allowing them to lift higher with a smaller chassis footprint compared to counterbalance units. Where are walkie stackers typically used? They are commonly used in small warehouses, manufacturing plants, retail backrooms, and operations where a full‑size forklift is not required. What lift heights and capacities are available? Typical walkie straddle stackers range from 2,000–4,000 lb with lift heights from 100″–192″+, depending on mast configuration and model. Can stackers handle standard pallets? Yes. Straddle legs allow the forks to enter standard pallets without interference, making them suitable for most warehouse pallet types. Are these units suitable for narrow aisles? Yes. Walkie stackers are designed for tight spaces and can operate in aisles narrower than those required for sit‑down forklifts. Are these units CSA‑certified? Yes. All walkie straddle stackers supplied by Premier Lift Equipment can be delivered CSA B335 compliant with full documentation for MOL and facility audits. Do stackers work in freezer environments? Some models can be configured with cold‑storage components, but suitability depends on the specific unit and temperature requirements. Do you offer service and parts support? Yes. Premier Lift Equipment provides full service, repairs, inspections, and parts support for all major walkie stacker brands.

- Supported Manufacturers

- Raymond / Crown / Toyota / Hyster / Yale / Cat / Mitsubishi / UniCarriers / Clark / Hangcha / Linde / Hyundai / Doosan / Big Joe / Noblelift

This 2025 BT SPE160L is a fork‑over walkie stacker with a fixed ride‑on operator platform, engine...

Discover more2025 BT SPE160L | 3,527 lb Capacity | Mast Height Not Specified | 24V Electric | Fixed Ride‑On Platform | Fork‑Over Stacker | CSA Certified | Brampton ON

- Capacity

- 3527

- Load Center

- 24"

- Fuel Type

- Electric

This 2016 Crown SX3000‑40 is a CSA‑certified 4,000 lb walkie stacker engineered for dock work, pa...

Discover more2016 Crown SX3000‑40 – CSA Certified Walkie Stacker | 4,000 lb | 87"/129" Mast | 24V Electric | Side Shift | Brampton ON

- Capacity

- 4000

- Load Center

- 24"

- Fuel Type

- Electric

This 2019 Toyota 6BRW15 is a 3,000 lb walkie reach truck with exceptionally low usage — only 102 ...

Discover more2019 Toyota 6BRW15 | Walkie Reach Truck | 3,000 lb | 83/180” Mast | Sideshift | 30” Forks | 102 Hours | Brampton ON

- Capacity

- 3000

- Load Center

- 24

- Raised Mast Height

- 180

This 2019 Toyota 6BRW15 is a 3,000 lb walkie reach truck with extremely low hours — only 288 hour...

Discover more2019 Toyota 6BRW15 | Walkie Reach Truck | 3,000 lb | 83/180” Triple Mast | Sideshift | 30” Forks | 288 Hours | Brampton ON

- Capacity

- 3000

- Load Center

- 24

- Raised Mast Height

- 180

This 2022 Raymond RSS30 walkie straddle stacker is CSA/MOL certified and engineered for narrow‑ai...

Discover more2022 Raymond RSS30 – Electric Walkie Straddle Stacker | 3,000 lb | Triplex Mast (189”) | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 3000

- Load Center

- 24"

- Raised Mast Height

- 189

This professionally reconditioned 2019 Toyota 8BWS13 walkie straddle stacker is CSA/MOL certified...

Discover more2019 Toyota 8BWS13 – Electric Walkie Straddle Stacker | 2,500 lb | 104” Lift | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 2500 LBS

- Load Center

- 24"

- Raised Mast Height

- 104

This reconditioned electric walkie reach stacker is CSA/MOL certified for narrow‑aisle pallet han...

Discover moreElectric Walkie Reach Stacker – 3,000 lb – 150” Lift – Triple‑Stage Mast – 42–48” Forks – 24V Electric – CSA/MOL Certified – Battery & Charger Optional

- Capacity

- 3000 LBS.

- Mast Spec

- 71/150

- Mast Type

- 3 stage

This 2021 Noblelift H‑5440 is a compact, manual‑push electric‑lift straddle stacker engineered fo...

Discover more2021 Noblelift H‑5440 – Manual‑Push Electric Walkie Straddle Stacker | 2,200 lb | 137.8” Lift | Adjustable Straddle Legs | Battery & Charger Included | CSA/MOL Certified | Brampton ON

- Capacity

- 2200 LBS.

- Load Center

- 24"

- Raised Mast Height

- 137.8

This professionally reconditioned 2019 Yale MSW025 walkie straddle stacker is CSA/MOL certified a...

Discover more2019 Yale MSW025 – Electric Walkie Straddle Stacker | 2,500 lb | Adjustable Baselegs | 104” Lift | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 2500 LBS.

- Load Center

- 24"

- Raised Mast Height

- 104

This professionally reconditioned 2014 Raymond RSS40 walkie straddle stacker is CSA/MOL certified...

Discover more2014 Raymond RSS40 – Electric Walkie Straddle Stacker | 4,000 lb | 150” Lift | Triple‑Stage Mast | Side Shift | CSA Certified | Battery Included | Brampton ON

- Capacity

- 4000 LBS.

- Load Center

- 24"

- Raised Mast Height

- 150

This CSA‑certified 2012 Yale MSW030‑F is a compact, high‑precision walkie straddle stacker engine...

Discover more2012 Yale MSW030‑F – Electric Walkie Straddle Stacker | 3,000 lb | 157” Lift | Triple‑Stage Mast | Side Shift | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 3000 LBS.

- Load Center

- 24"

- Raised Mast Height

- 157

This 2013 Yale MSW040‑E walkie straddle stacker is CSA/MOL certified and engineered for precise p...

Discover more2013 Yale MSW040‑E – Electric Walkie Straddle Stacker | 4,000 lb | 100” Lift | Side Shift | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 4000

- Raised Mast Height

- 100

- Lowered Mast Height

- 72

This professionally reconditioned 2012 Raymond RAS25 walkie straddle stacker is CSA/MOL certified...

Discover more2012 Raymond RAS25 – Walkie Straddle Stacker | 2,500 lb | Electric | CSA/MOL Certified | Battery & Charger Extra | Brampton ON (GTA)

- Capacity

- 2500 lbs

- Load Center

- 24"

- Raised Mast Height

- 104

This CSA‑certified 2018 Crown SX3000‑40 is a high‑capacity walkie straddle stacker engineered for...

Discover more2018 Crown SX3000‑40 – CSA Walkie Straddle Stacker | 4,000 lb | 128” Lift | Brampton ON

- Fuel Type

- Electric

- Raised Mast Height

- 128

- Lowered Mast Height

- 87

This compact electric walkie forkover stacker is designed for open‑bottom pallet handling, tight‑...

Discover moreElectric Walkie Forkover Stacker – 2,200 lb – 61” Lift – Telescopic Mast – 45” Forks – 24V Electric – CSA/MOL Certified – Battery + Built‑In Charger Included

- Load Center

- 24"

- Capacity

- 2200 lbs.

- Fuel Type

- Electric

The 2018 Raymond RSS40 is a high‑performance electric walkie straddle stacker designed for precis...

Discover more2018 Raymond RSS40 – Electric Walkie Straddle Stacker | 4,000 lb | 128” Lift | Side Shift | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 4000 lbs.

- Raised Mast Height

- 128

- Lowered Mast Height

- 87

This CSA‑certified 2017 Raymond 6210 is a compact electric walkie straddle stacker built for tigh...

Discover more2017 Raymond 6210 – Electric Walkie Straddle Stacker | 2,200 lb | 104” Lift | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 2500

- Raised Mast Height

- 104

- Lowered Mast Height

- 71

The 2015 Yale MSW040SFN is a heavy‑duty electric walkie straddle stacker built for reliable palle...

Discover more2015 Yale MSW040SFN – Electric Walkie Straddle Stacker | 4,000 lb | 153” Lift | Triple‑Stage Mast | Side Shift | CSA/MOL Certified | Battery & Charger Extra | Brampton ON

- Capacity

- 4000

- Load Center

- 24"

- Raised Mast Height

- 153

This reconditioned electric walkie reach stacker is CSA/MOL certified for narrow‑aisle pallet han...

Discover moreElectric Walkie Reach Stacker – 3,000 lb – 179” Lift – Triple‑Stage Mast – 42” Forks – Side Shift – 24V Electric – CSA/MOL Certified – Battery & Charger Optional

- Capacity

- 3000

- Mast

- Three Stage

- Mast Spec

- 83"/179"

This professionally reconditioned 2018 Big Joe PDS‑25‑130 walkie straddle stacker is CSA/MOL cert...

Discover more2018 Big Joe PDS‑25‑130 – Electric Walkie Straddle Stacker | 2,500 lb | 130” Lift | Adjustable Straddle Legs | CSA/MOL Certified | Battery & Charger Included | Brampton ON

- Capacity

- 2500

- Load Center

- 24"

- Raised Mast Height

- 130

This reconditioned electric walkie counterbalance forklift is designed for tight‑aisle warehouse ...

Discover more

This reconditioned electric walkie straddle stacker is CSA/MOL certified for tight‑aisle pallet h...

Discover more2009 Crown W2T‑130 Walkie Straddle Stacker | CSA/MOL Certified | 2,000 lb | 130” Lift | Adjustable Straddle Legs | 24V Electric | Battery & Charger Included | Brampton ON

- Capacity

- 2000

- Load Center

- 24"

- Raised Mast Height

- 130