Advanced Filters

Category

Subcategory

Manufacturer

Condition

Lowered Mast Height

Raised Mast Height

Capacity

Environmental & Facility Safety Systems include all CSA‑approved and WHMIS‑aligned tools used to ...

Discover moreEnvironmental & Facility Safety Systems – CSA‑Approved Spill Control, Hazard‑Zone Identification & Facility‑Wide Safety Tools

- Category Overview

- This page represents our Environmental Safety Systems category. Use it to compare spill‑control products, air‑quality solutions, hazardous‑material containment tools, and environmental‑protection systems designed for warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include spill kits, absorbents, containment berms, ventilation tools, air‑quality monitors, drain‑protection devices, and hazardous‑material storage solutions. All systems are selected to reduce environmental risk, support regulatory compliance, and maintain safe, CSA‑aligned facility operations. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of environmental‑safety products are included in this category? This category includes spill kits, absorbents, containment berms, air‑quality monitors, ventilation tools, drain‑protection devices, and hazardous‑material storage solutions. Why is environmental safety important in warehouse and industrial operations? Environmental‑safety systems reduce spill risk, protect air quality, prevent contamination, and support CSA‑aligned and regulatory compliance. Do you offer spill‑control and containment products? Yes. Spill kits, absorbents, neutralizers, containment berms, and spill‑response tools are available for a wide range of industrial materials. Are air‑quality or ventilation solutions available? Yes. Air‑quality monitors, hydrogen‑gas detectors, ventilation systems, and airflow‑monitoring tools are available for enclosed or high‑risk areas. Do you supply hazardous‑material storage solutions? Yes. Flammable‑storage cabinets, corrosive‑material cabinets, and compliant containment systems are available for regulated materials. Are these products suitable for all facility types? Yes. Environmental‑safety systems are suitable for warehouses, 3PL operations, manufacturing plants, cold storage, and industrial facilities. Do these tools support CSA‑aligned safety practices? Yes. All products are selected to support environmental‑protection requirements aligned with CSA and regulatory expectations. Do you provide installation or compliance guidance? Yes. Premier Lift Equipment offers installation support, environmental‑safety planning, and compliance‑aligned guidance. Do you ship environmental‑safety products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse environments, industrial facilities, and CSA/MOL/WHMIS safety‑program requirements.

Warehouse Lighting & High‑Visibility Systems include all CSA‑approved lighting and visibility too...

Discover moreWarehouse Lighting & High‑Visibility Systems – CSA‑Approved Aisle Lighting, Task Illumination & Visibility Enhancements

- Category Overview

- This page represents our Warehouse Lighting & High‑Visibility Systems category. Use it to compare aisle‑lighting solutions, task‑illumination tools, high‑visibility fixtures, and visibility‑enhancement systems designed for warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include LED aisle lights, task lights, motion‑activated fixtures, emergency lighting, pedestrian‑zone visibility tools, and high‑output illumination systems for mixed‑traffic environments. All solutions are selected to improve visibility, reduce collision risk, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of lighting and visibility products are included in this category? This category includes LED aisle lights, task‑illumination fixtures, motion‑activated lighting, emergency lighting, and high‑visibility warehouse lighting systems. Why is proper warehouse lighting important? Effective lighting improves visibility, reduces collision risk, enhances operator awareness, and supports CSA‑aligned safe‑operation practices. Do you offer aisle‑lighting and task‑illumination systems? Yes. Aisle‑lighting systems, task lights, and high‑output fixtures are available for picking zones, racking aisles, and mixed‑traffic areas. Are motion‑activated or energy‑efficient options available? Yes. Motion‑activated, daylight‑harvesting, and energy‑efficient LED systems are available to reduce operating costs and improve visibility. Do you supply lighting for pedestrian‑zone visibility? Yes. Pedestrian‑zone visibility lights, walkway‑illumination tools, and high‑visibility indicators are available for high‑risk areas. Do you offer emergency or backup lighting? Yes. Emergency lighting, exit signs, and backup illumination systems are available for compliance and safety‑critical environments. Are these lighting systems suitable for all facility types? Yes. Lighting solutions are available for warehouses, 3PL operations, manufacturing plants, cold storage, and industrial facilities. Do you provide installation or upgrade support? Yes. Premier Lift Equipment offers installation, lighting‑layout guidance, and upgrade support for warehouse lighting systems. Do you ship lighting products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse layouts, racking systems, forklifts, and CSA/MOL visibility‑safety requirements.

Dock Communication & Alert Systems include all CSA‑approved visual and audible safety tools used ...

Discover moreDock Communication & Alert Systems – CSA‑Approved Visual, Audible & Trailer‑Presence Safety Tools

- Category Overview

- This page represents our Dock Communication & Alert Systems category. Use it to compare visual‑alert tools, audible warning systems, trailer‑presence indicators, and dock‑area communication products designed to support safe loading and unloading operations. Products include dock signal lights, interior/exterior communication lights, audible alarms, trailer‑presence sensors, motion‑activated alerts, and dock‑status indicators used in warehouses, 3PL operations, manufacturing plants, and industrial yards. All solutions are selected to improve visibility, enhance communication between drivers and dock staff, and support CSA‑aligned dock‑safety practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of dock communication systems are included in this category? This category includes dock signal lights, interior/exterior communication lights, audible alarms, trailer‑presence sensors, and dock‑status indicators. Why are communication and alert systems important at loading docks? They improve visibility, enhance communication between drivers and dock staff, prevent premature departure, and support CSA‑aligned dock‑safety practices. Do you offer trailer‑presence or motion‑activated alert systems? Yes. Trailer‑presence indicators, motion‑activated alerts, and sensor‑based warning systems are available for high‑risk dock areas. Are interior and exterior dock lights available? Yes. Red/green communication lights, dock‑status indicators, and visual‑alert systems are available for both inside and outside the dock bay. Do you supply audible alarms for dock operations? Yes. Audible warning devices, departure alarms, and hazard‑alert systems are available for mixed‑traffic and high‑noise environments. Are these systems compatible with all dock types? Yes. Dock communication and alert systems are suitable for standard docks, recessed docks, drive‑in docks, and yard‑truck operations. Do these tools support CSA‑aligned safety practices? Yes. All products are selected to enhance visibility, communication, and hazard awareness in accordance with CSA‑aligned dock‑safety expectations. Do you provide installation or dock‑layout guidance? Yes. Premier Lift Equipment offers installation, layout planning, and dock‑safety system integration support. Do you ship dock‑communication products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all dock‑levelers, trailers, yard trucks, warehouse doors, and CSA/MOL dock‑area safety requirements.

Pedestrian‑Zone Safety Systems include all CSA‑approved walkway‑control and collision‑prevention ...

Discover morePedestrian‑Zone Safety Systems – CSA‑Approved Walkway Control, Collision‑Prevention & High‑Visibility Safety Tools

- Category Overview

- This page represents our Pedestrian‑Zone Safety Systems category. Use it to compare walkway‑control tools, collision‑prevention systems, visual‑guidance products, and high‑visibility safety solutions designed to protect pedestrians in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include pedestrian‑warning lights, floor‑marking systems, zone‑lighting tools, intersection‑safety devices, visual‑alert systems, and mixed‑traffic safety solutions. All systems are selected to improve visibility, reduce collision risk, and support CSA‑aligned pedestrian‑safety practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of pedestrian‑zone safety products are included in this category? This category includes pedestrian‑warning lights, floor‑marking systems, zone‑lighting tools, intersection‑safety devices, and visual‑alert systems. Why are pedestrian‑zone safety systems important? They reduce collision risk, improve visibility, guide foot traffic, and support CSA‑aligned safety practices in mixed‑traffic environments. Do you offer visual‑alert or warning‑light systems? Yes. Options include pedestrian‑warning lights, zone‑lighting tools, and visual‑alert indicators for high‑traffic areas. Are floor‑marking and walkway‑control products available? Yes. Floor tape, hazard markers, walkway dividers, and visual‑guidance systems are available for controlled pedestrian movement. Do you supply intersection‑safety devices? Yes. Intersection‑alert systems, corner‑visibility tools, and motion‑activated warning devices are available for blind‑spot areas. Are these products compatible with all warehouse layouts? Yes. Pedestrian‑zone safety systems are modular and can be configured for aisles, intersections, docks, and custom facility layouts. Do these tools support CSA‑aligned safety practices? Yes. All products are selected to enhance visibility, guide pedestrian flow, and reduce collision risk in accordance with CSA‑aligned safety expectations. Do you provide installation or layout guidance? Yes. Premier Lift Equipment offers installation, layout planning, and pedestrian‑zone design support. Do you ship pedestrian‑zone safety products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse layouts, forklift fleets, pedestrian walkways, and CSA/MOL safety‑zone requirements.

Warehouse Barriers & Fencing includes all CSA‑approved impact‑protection and pedestrian‑zone safe...

Discover moreWarehouse Barriers & Fencing – CSA‑Approved Impact Protection & Pedestrian‑Zone Safety Systems

- Category Overview

- This page represents our Warehouse Barriers & Fencing category. Use it to compare impact‑protection systems, pedestrian‑zone barriers, modular fencing, and facility‑safety products designed to separate people from equipment and protect high‑risk areas. Products include guard rails, safety fencing, modular barrier systems, rack‑end protectors, column guards, and pedestrian‑walkway barriers used in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All solutions are selected to reduce collision risk, protect infrastructure, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of barriers and fencing are included in this category? This category includes guard rails, modular fencing, pedestrian‑zone barriers, rack‑end protectors, column guards, and impact‑protection systems. Why are barriers and fencing important in warehouse environments? Barriers and fencing separate pedestrians from equipment, protect infrastructure, reduce collision risk, and support CSA‑aligned facility‑safety practices. Do you offer guard rails and impact‑protection systems? Yes. Heavy‑duty guard rails, modular barrier systems, and impact‑rated protection products are available for high‑traffic areas. Are pedestrian‑walkway barriers available? Yes. Pedestrian‑zone barriers, walkway dividers, and visual‑guidance systems are available for mixed‑traffic environments. Do you supply fencing for restricted or high‑risk areas? Yes. Modular fencing systems are available for machine zones, battery rooms, equipment areas, and controlled‑access spaces. Are these products compatible with all warehouse layouts? Yes. Barriers and fencing systems are modular and can be configured for aisles, docks, corners, and custom facility layouts. Do these tools support CSA‑aligned safety practices? Yes. Barriers and fencing support CSA‑aligned facility‑safety requirements by reducing collision risk and improving pedestrian separation. Do you provide installation or layout guidance? Yes. Premier Lift Equipment offers installation, layout planning, and safety‑zone design support. Do you ship barriers and fencing across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all warehouse racking, dock‑levelers, forklift fleets, pedestrian walkways, and industrial safety infrastructure.

Wheel Chocks (Dock & Yard Safety) includes all CSA‑approved trailer‑restraint and roll‑away preve...

Discover moreWheel Chocks (Dock & Yard Safety) – CSA‑Approved Trailer Restraint & Roll‑Away Prevention Systems

- Category Overview

- This page represents our Wheel Chocks category. Use it to compare CSA‑approved trailer‑restraint tools, roll‑away‑prevention systems, and dock‑safety products designed for warehouses, 3PL operations, manufacturing plants, and industrial yards. Products include rubber and urethane wheel chocks, heavy‑duty trailer chocks, chain‑restrained systems, dock‑position indicators, and yard‑safety accessories used to secure trailers during loading and unloading. All solutions are selected to prevent trailer movement, reduce dock‑area hazards, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of wheel chocks are included in this category? This category includes rubber wheel chocks, urethane wheel chocks, heavy‑duty trailer chocks, chain‑restrained systems, and dock‑area roll‑away‑prevention tools. Why are wheel chocks important for dock safety? Wheel chocks prevent trailer movement during loading and unloading, reducing roll‑away risk and supporting CSA‑aligned dock‑safety practices. Do you offer heavy‑duty trailer chocks for transport trucks? Yes. Heavy‑duty chocks are available for transport trailers, yard trucks, and industrial vehicles. Are chain‑restrained or tethered chocks available? Yes. Chain‑restrained and tethered chocks are available to prevent loss, improve compliance, and ensure consistent dock‑area use. Do you supply wheel chocks for uneven or outdoor surfaces? Yes. Outdoor‑rated and high‑traction chocks are available for gravel, asphalt, and yard environments. Are these products compatible with all trailer types? Yes. Wheel chocks are suitable for standard trailers, container chassis, yard trucks, and industrial vehicles. Do these tools support CSA‑aligned safety practices? Yes. Wheel chocks support CSA‑aligned dock‑safety requirements by preventing unintended trailer movement. Do you provide installation or dock‑safety guidance? Yes. Premier Lift Equipment offers guidance on dock‑safety setup, signage placement, and compliance practices. Do you ship wheel chocks across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all trailers, dock‑levelers, yard trucks, forklifts, and warehouse loading‑bay infrastructure.

Dock Safety & Lighting covers all CSA‑approved lighting and visibility systems used in loading ba...

Discover moreDock Safety & Lighting – CSA‑Approved Loading‑Bay Visibility & Protection Systems

- Category Overview

- This page represents our Warehouse Lighting category. Use it to compare high‑visibility, energy‑efficient lighting systems designed for warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include LED high‑bay fixtures, task lighting, aisle‑lighting systems, motion‑activated fixtures, emergency lighting, and visibility‑enhancing upgrades for forklift and pedestrian zones. All solutions are selected to improve visibility, reduce energy consumption, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of lighting products are included in this category? This category includes LED high‑bay fixtures, task lighting, aisle‑lighting systems, motion‑activated fixtures, emergency lighting, and visibility‑enhancing warehouse lighting solutions. Why is proper warehouse lighting important? Effective lighting improves visibility, reduces collision risk, enhances operator awareness, and supports CSA‑aligned safe‑operation practices. Do you offer LED high‑bay lighting? Yes. LED high‑bay fixtures are available for warehouses, distribution centers, and industrial facilities requiring high‑output illumination. Are motion‑activated or energy‑efficient options available? Yes. Motion‑activated, daylight‑harvesting, and energy‑efficient LED systems are available to reduce operating costs and improve visibility. Do you supply lighting for forklift or pedestrian zones? Yes. Aisle‑lighting systems, task lighting, and visibility‑enhancing fixtures are available for mixed‑traffic areas and high‑risk zones. Do you offer emergency or backup lighting? Yes. Emergency lighting, exit signs, and backup illumination systems are available for compliance and safety‑critical environments. Are these lighting systems suitable for all facility types? Yes. Lighting solutions are available for warehouses, 3PL operations, manufacturing plants, cold storage, and industrial facilities. Do you provide installation or upgrade support? Yes. Premier Lift Equipment offers installation, lighting‑layout guidance, and upgrade support for warehouse lighting systems. Do you ship lighting products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all dock equipment, forklifts, pallet trucks, and warehouse infrastructure.

Forklift Safety Accessories include all CSA‑approved operator‑protection, visibility, and on‑truc...

Discover moreForklift Safety Accessories – CSA‑Approved Operator‑Protection, Visibility & On‑Truck Safety Tools

- Category Overview

- This page represents our Forklift Safety Accessories category. Use it to compare operator‑protection tools, visibility enhancements, warning systems, and on‑truck safety accessories designed to support CSA‑aligned forklift operation. Products include blue/red safety lights, alarms, strobe lights, mirrors, cameras, seat‑belt systems, overhead‑guard accessories, and pedestrian‑awareness tools used in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All solutions are selected to improve visibility, reduce collision risk, and support safe, compliant forklift operation. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of forklift safety accessories are included in this category? This category includes blue/red safety lights, alarms, strobe lights, mirrors, cameras, seat‑belt systems, overhead‑guard accessories, and pedestrian‑awareness tools. Why are forklift safety accessories important? Safety accessories improve visibility, reduce collision risk, support operator awareness, and help maintain CSA‑aligned safe‑operation practices. Do you offer forklift‑mounted visibility tools? Yes. Options include blue/red spotlights, strobe lights, rear‑facing lights, and wide‑angle visibility mirrors. Are pedestrian‑awareness systems available? Yes. Visual warning systems, zone‑lighting tools, and awareness indicators are available for mixed‑traffic environments. Do you supply operator‑protection accessories? Yes. Seat‑belt systems, overhead‑guard accessories, and operator‑station safety tools are available for most forklift models. Are these accessories compatible with all forklift brands? Yes. Most forklift‑mounted safety accessories are universal or available with model‑specific mounting options. Do these products support CSA‑aligned safety practices? Yes. All accessories are selected to support visibility, awareness, and operator‑protection requirements aligned with CSA B335. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and integration support for forklift safety accessories. Do you ship forklift safety accessories across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, mast types, carriage classes, and CSA/MOL operator‑safety requirements.

CSA Certification & Inspection Services include all CSA/MOL‑aligned inspection, documentation, an...

Discover moreCSA Certification & Inspection Services – CSA/MOL Compliance, Annual Safety Audits & Equipment‑Certification Programs

- Category Overview

- This page represents our CSA Certification & Inspection Services category. Use it to compare CSA/MOL‑aligned inspection programs, annual safety audits, equipment‑certification services, and compliance documentation for forklifts, aerial lifts, battery rooms, and warehouse operations. Services include on‑site inspections, certification renewals, safety‑system evaluations, and audit‑ready reporting designed to support regulatory compliance in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All programs are delivered by certified technicians and structured to maintain safe, compliant, and fully documented equipment fleets. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of certification and inspection services are included in this category? This category includes CSA‑aligned equipment inspections, annual safety audits, certification renewals, compliance documentation, and safety‑system evaluations. Why are CSA certifications important? CSA certifications verify that equipment meets safety standards, supports MOL compliance, and ensures operators are using properly inspected and approved machinery. Do you offer on‑site inspections? Yes. Certified technicians provide on‑site inspections for forklifts, aerial lifts, battery rooms, and warehouse safety systems. What equipment can be certified? Forklifts, reach trucks, order pickers, walkies, aerial lifts, tow tractors, and other material‑handling equipment can be certified or recertified. Do you provide annual or scheduled safety audits? Yes. Annual, semi‑annual, and custom audit programs are available for facilities requiring ongoing compliance tracking. Do you supply documentation for MOL or internal audits? Yes. Inspection reports, certification records, and compliance documentation are provided in audit‑ready formats. Are certification services compatible with all equipment brands? Yes. Certification and inspection services apply to all major forklift and aerial‑lift brands. Do you offer guidance on setting up compliance programs? Yes. Premier Lift Equipment provides support for establishing inspection routines, documentation workflows, and CSA‑aligned compliance practices. Do you offer fleet‑wide certification programs? Yes. Multi‑unit and multi‑facility certification programs are available for warehouses, 3PL operations, and industrial fleets. Do you provide service across Canada and the United States? Yes. Certification and inspection services are available across Canada, with extended support options for U.S. facilities.

- Supported Manufacturers

- Supported Manufacturers

Forklift Stability & Load‑Handling Safety includes all CSA‑approved tools used to improve load co...

Discover moreForklift Stability & Load‑Handling Safety – CSA‑Approved Load Control, Stability Tools & Mast‑Tilt Safety Systems

- Category Overview

- This page represents our Forklift Stability & Load‑Handling Safety category. Use it to compare load‑control tools, stability‑enhancing accessories, mast‑tilt safety systems, and operator‑awareness products designed to support safe lifting practices in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include load backrests, tilt‑indicators, stability‑assist tools, load‑weight indicators, and accessories that help operators maintain proper load balance and visibility. All solutions are selected to reduce tip‑over risk, improve load control, and support CSA‑aligned safe‑operation standards. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of stability and load‑handling tools are included in this category? This category includes load backrests, mast‑tilt indicators, load‑weight indicators, stability‑assist tools, and accessories that support safe lifting and load control. Why is forklift stability important? Stability is critical for preventing tip‑overs, maintaining load balance, and ensuring safe operation in high‑traffic or uneven‑surface environments. Do you offer load backrests? Yes. Load backrests are available for most forklift models to help secure loads and prevent product from shifting toward the operator. Are mast‑tilt or angle‑indicators available? Yes. Mast‑tilt indicators and angle‑gauges help operators maintain proper mast position during lifting, stacking, and travel. Do you supply load‑weight or overload indicators? Yes. Load‑weight indicators and overload‑alert systems are available to help operators avoid exceeding rated capacity. Are these products compatible with all forklift brands? Yes. Most stability and load‑handling accessories are universal or available with model‑specific mounting options. Do these tools support CSA‑aligned safety practices? Yes. Stability and load‑handling accessories support CSA‑aligned safe‑operation standards by improving operator awareness and reducing risk. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and integration support for stability and load‑handling accessories. Do you ship these products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, mast types, carriage sizes, and CSA/MOL load‑handling requirements.

Operator Protection & Ergonomics includes all CSA‑approved comfort, safety, and fatigue‑reduction...

Discover moreOperator Protection & Ergonomics – CSA‑Approved Comfort, Safety & Fatigue‑Reduction Systems

- Category Overview

- This page represents our Operator Protection & Ergonomics category. Use it to compare comfort‑enhancing, fatigue‑reducing, and safety‑focused accessories designed to support forklift operators in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products include operator fans, suspension seats, ergonomic mats, cab enclosures, weather‑protection systems, vibration‑reduction components, and safety‑enhancing visibility tools. All solutions are selected to improve operator comfort, reduce strain, and support CSA‑aligned safe‑operation practices. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of operator‑protection products are included in this category? This category includes suspension seats, operator fans, ergonomic mats, cab enclosures, weather‑protection systems, and vibration‑reduction accessories. Why is operator ergonomics important? Ergonomic equipment reduces fatigue, improves comfort, supports longer shifts, and helps operators maintain safe, consistent performance. Do you offer suspension or comfort‑enhanced seating? Yes. Suspension seats, high‑back seats, and comfort‑enhanced seating options are available for most forklift brands. Are cab enclosures or weather‑protection systems available? Yes. Soft and hard cab enclosures, heaters, and weather‑protection systems are available for indoor/outdoor operations. Do these products support CSA‑aligned safety practices? Yes. Ergonomic and protection accessories help operators maintain visibility, posture, and control, supporting CSA‑aligned safe‑operation standards. Are these products compatible with all forklift brands? Yes. Most operator‑protection and ergonomic accessories are universal or available with model‑specific mounting options. Do you offer vibration‑reduction or fatigue‑reduction tools? Yes. Options include anti‑vibration mats, ergonomic floor pads, and comfort‑enhancing operator‑station upgrades. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and integration support for operator‑protection accessories. Do you ship operator‑protection products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, warehouse vehicles, and CSA/MOL operator‑safety requirements.

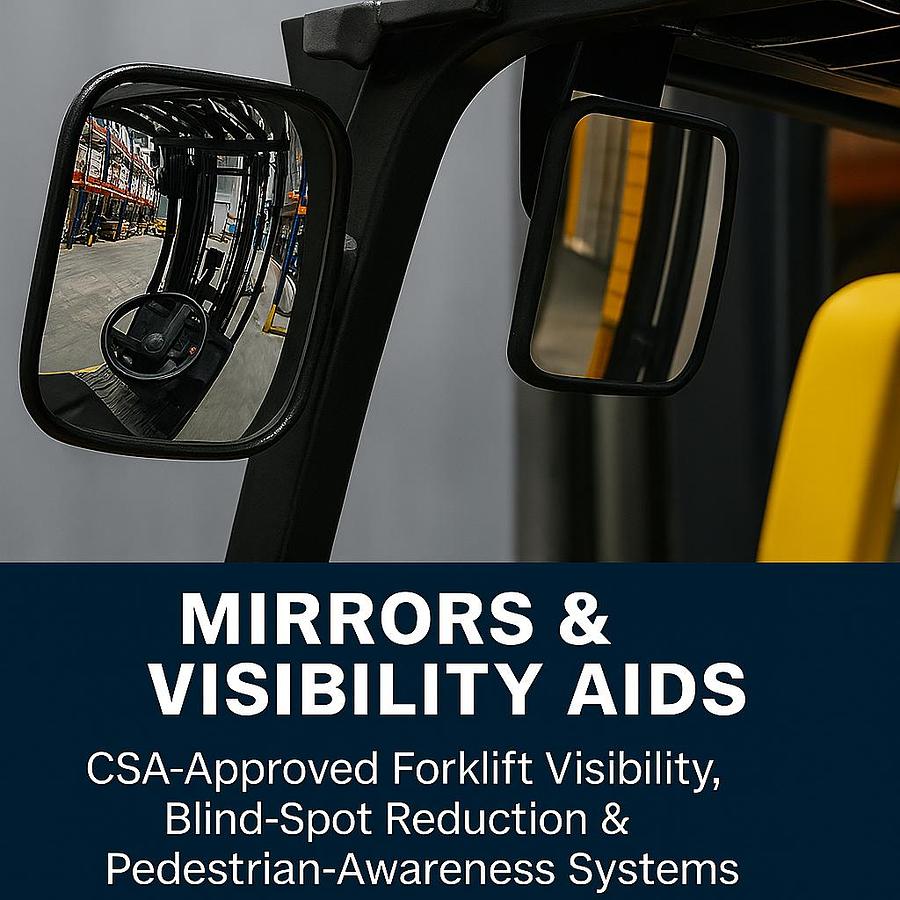

Mirrors & Visibility Aids include all CSA‑approved visibility tools used to reduce blind spots, i...

Discover moreMirrors & Visibility Aids – CSA‑Approved Forklift Visibility, Blind‑Spot Reduction & Pedestrian‑Awareness Systems

- Category Overview

- This page represents our Mirrors & Visibility Aids category. Use it to compare forklift‑mounted mirrors, convex mirrors, dome mirrors, pedestrian‑awareness systems, and visibility tools designed to reduce blind spots and improve operator awareness in warehouses, 3PL operations, manufacturing plants, and industrial facilities. Products support CSA‑aligned visibility requirements and help prevent collisions in high‑traffic and mixed‑pedestrian environments. All solutions are selected to enhance sightlines, improve hazard detection, and support safe material‑handling workflows. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of visibility aids are included in this category? This category includes forklift‑mounted mirrors, convex mirrors, dome mirrors, pedestrian‑awareness systems, and blind‑spot reduction tools. Why are visibility aids important for forklift operations? Visibility aids reduce blind spots, improve operator awareness, and help prevent collisions in high‑traffic warehouse environments. Do you offer forklift‑mounted mirrors? Yes. Options include overhead guards mirrors, side‑mount mirrors, rear‑view mirrors, and wide‑angle visibility mirrors. Are convex and dome mirrors available for facility installation? Yes. Convex and dome mirrors are available for intersections, blind corners, and high‑traffic pedestrian zones. Do these products support CSA‑aligned safety practices? Yes. Visibility aids support CSA‑aligned operational safety by improving sightlines and reducing collision risk. Are these products compatible with all forklift brands? Yes. Most forklift‑mounted mirrors and visibility tools are universal or available with model‑specific mounting options. Do you offer pedestrian‑awareness systems? Yes. Options include visual warning systems, zone‑lighting tools, and awareness indicators for mixed‑traffic areas. Do you provide installation support? Yes. Premier Lift Equipment offers installation, mounting guidance, and safety‑equipment integration support. Do you ship visibility products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, warehouse vehicles, pedestrian‑safety systems, and CSA/MOL visibility requirements.

Inspection Logs & Compliance Systems include all CSA‑approved documentation tools used to support...

Discover moreInspection Logs & Compliance Systems – CSA‑Approved Checklists, Safety Documentation & Audit‑Ready Recordkeeping

- Category Overview

- This page represents our Inspection Logs & Compliance Systems category. Use it to compare CSA‑approved checklists, digital and paper inspection logs, safety documentation tools, and audit‑ready recordkeeping systems for forklifts, aerial lifts, battery rooms, and warehouse operations. Products support daily pre‑shift inspections, maintenance tracking, incident documentation, and regulatory compliance for warehouses, 3PL operations, manufacturing plants, and industrial facilities. All solutions are designed to improve visibility, reduce risk, and maintain consistent, audit‑ready safety records. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of inspection and compliance tools are included in this category? This category includes CSA‑approved checklists, daily inspection books, digital log systems, maintenance record forms, incident documentation tools, and audit‑ready compliance binders. Why are inspection logs important? Inspection logs support CSA‑aligned pre‑shift checks, reduce equipment‑related risks, and provide documented proof of compliance during audits or investigations. Do you offer forklift‑specific inspection books? Yes. Forklift inspection books are available for electric, propane, diesel, reach trucks, order pickers, walkies, and aerial lifts. Are digital inspection systems available? Yes. Digital log systems and cloud‑based recordkeeping tools are available for facilities transitioning away from paper documentation. Do these tools help with MOL or internal audits? Yes. Inspection logs and compliance systems provide structured, audit‑ready documentation that supports MOL reviews and internal safety audits. Do you offer battery‑room inspection and compliance tools? Yes. Battery‑room checklists, eyewash inspection logs, spill‑response documentation, and charging‑zone compliance forms are available. Are these products compatible with all equipment brands? Yes. Inspection logs and compliance systems are universal and suitable for all forklift and material‑handling equipment brands. Do you provide training or guidance on implementing compliance systems? Yes. Premier Lift Equipment offers guidance on setting up inspection routines, documentation workflows, and CSA‑aligned compliance practices. Do you ship compliance products across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift brands, aerial lifts, warehouse equipment, and CSA/MOL inspection protocols.

Battery Room Safety includes all CSA‑approved spill‑response, PPE, eyewash, ventilation, and char...

Discover moreBattery Room Safety – CSA‑Approved Spill Response, PPE & Charging‑Zone Compliance Systems

- Category Overview

- This page represents our Battery Room Safety category. Use it to compare spill‑response kits, PPE, ventilation solutions, eyewash stations, signage, and charging‑zone compliance tools designed for CSA‑aligned battery‑handling environments. Products support safe charging, watering, maintenance, and emergency response for industrial forklift batteries in warehouses, 3PL operations, manufacturing plants, and distribution centers. All equipment is selected to reduce risk, improve visibility, and maintain compliance in high‑hazard battery‑charging areas. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of safety products are included in this category? This category includes spill‑response kits, PPE, eyewash stations, ventilation solutions, acid‑resistant flooring, signage, and charging‑zone compliance tools. Why is battery room safety important? Battery rooms contain corrosive electrolytes, hydrogen‑gas risks, and high‑current charging equipment. Proper safety tools reduce hazards and support CSA‑aligned compliance. Do you offer spill‑response and neutralization kits? Yes. Spill kits, neutralizing agents, absorbents, and acid‑resistant cleanup tools are available for emergency response. What PPE is required in battery‑charging areas? Common PPE includes face shields, chemical‑resistant gloves, aprons, safety eyewear, and footwear designed for corrosive environments. Do you supply eyewash or emergency‑shower stations? Yes. Portable and plumbed eyewash stations are available for battery‑handling and spill‑risk areas. Do you offer ventilation or hydrogen‑gas monitoring solutions? Yes. Ventilation systems, hydrogen‑gas detectors, and airflow‑monitoring tools are available for enclosed charging rooms. Are these products compatible with all industrial battery types? Yes. Safety equipment is suitable for lead‑acid, AGM, gel, and lithium‑ion battery environments. Do you provide installation or compliance support? Yes. Premier Lift Equipment offers installation, inspections, and guidance for CSA‑aligned battery‑room compliance. Do you ship battery‑room safety equipment across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Manufacturers

- Compatible with all forklift battery chargers, industrial batteries, watering systems, and charging‑station infrastructure.

Material Handling Safety Equipment includes visibility, protection, compliance, and dock‑safety s...

Discover moreMaterial Handling Safety Equipment – CSA‑Approved Visibility, Protection & Compliance Tools

- Category Overview

- This page represents our Material Handling Safety Equipment category. Use it to compare visibility tools, pedestrian‑protection systems, forklift safety accessories, and facility‑protection products designed to support CSA‑aligned warehouse operations. Equipment options include blue/red safety lights, alarms, mirrors, cameras, guard rails, bollards, rack protectors, dock‑area safety products, and pedestrian‑awareness systems used in warehouses, 3PL operations, manufacturing plants, and industrial facilities. All products are selected to improve visibility, reduce collision risk, and support safe, compliant material‑handling workflows. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of safety equipment are included in this category? This category includes forklift‑mounted safety accessories, pedestrian‑awareness systems, guard rails, bollards, rack protectors, mirrors, alarms, dock‑area safety products, and visibility tools. Why is safety equipment important in material‑handling environments? Safety equipment reduces collision risk, improves visibility, protects pedestrians, and supports CSA‑aligned warehouse and industrial operations. Do you offer forklift‑mounted safety accessories? Yes. Options include blue/red safety lights, alarms, strobe lights, mirrors, cameras, and pedestrian‑awareness systems. Do you supply facility‑protection products? Yes. Guard rails, bollards, column protectors, rack protectors, and dock‑area safety products are available for high‑traffic and high‑risk areas. Are these products compatible with all forklift brands? Yes. Most forklift‑mounted safety accessories are universal or available with model‑specific mounting options. Do you offer installation or service support? Yes. Premier Lift Equipment provides installation, inspections, repairs, and safety‑equipment integration support. Do you ship safety equipment across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions. What industries typically use this equipment? Warehousing, 3PL, manufacturing, food distribution, retail, automotive, and industrial facilities.

- Supported Manufacturers

- Toyota · Raymond · Crown · Hyster · Yale · Cat · Mitsubishi · UniCarriers · Clark · Komatsu · Hyundai · Hangcha · BYD · Linde · STILL · Doosan · Bendi · Combilift · Drexel · Skyjack · Genie

When pedestrians enter forklift zones, visibility becomes non‑negotiable. This 9″×12″ Forklift Wa...

Discover moreForklift Warning Sign – Aluminum Caution Plate | 9″×12″ | Pre-Drilled | Indoor/Outdoor CSA Safety Alert | Brampton ON

- Material

- Weather‑resistant aluminum

- Dimensions

- 9″ W × 12″ H

- Weight

- 1 kg

When safety accessories need a secure anchor, this bracket kit delivers. The Universal Mounting B...

Discover moreUniversal Mounting Bracket Kit | 5,000 lb Break Strength | Bolt-On Safety Anchor | CSA Visual Zone | Brampton ON

- Type

- Universal mounting bracket kit (pair)

- Breaking Strength

- 5,000 lb

- Safe Working Load (SWL)

- 1,666 lb per bracket

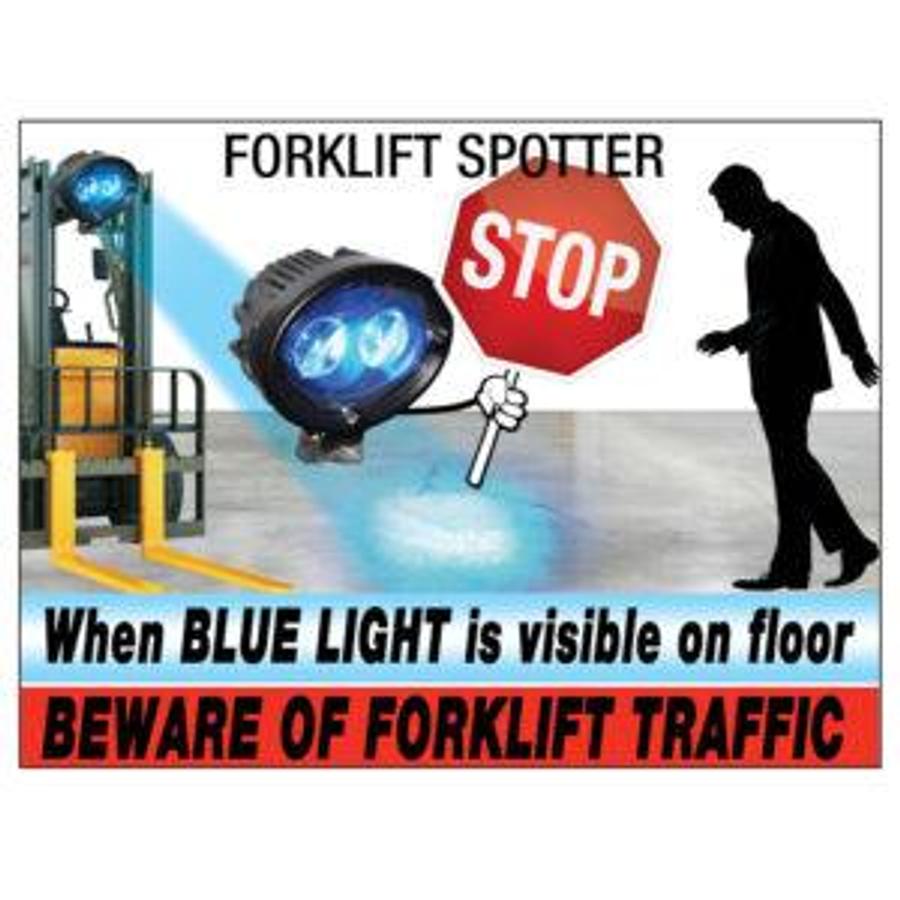

The Safe‑Lite Forklift Warning Light projects a high‑intensity blue spot beam 10–20 feet ahead or...

Discover moreSafe‑Lite Forklift Warning Light – Blue LED Spot Beam | 1300 Lumens | 9–64V | IP67 | CSA Visual Zone | Brampton ON

- Casing

- Aluminum with heat‑dissipating fins

- Weight

- 2 kg

- Led life rating

- 50,000 hours

The Forklift Spotter Safe Zone Complete Kit delivers a full 360° LED pedestrian awareness system ...

Discover moreForklift Spotter Safe Zone Complete Kit | 360° Pedestrian Awareness System | CSA/MOL Visual Zone | Brampton ON

- Weight

- 9 kg

- Coverage

- 360° visual projection

- Compatibility

- Electric, propane, diesel forklifts; reach trucks; pallet trucks

The Forklift Side Spotter – Red LED Safety Zone Light creates a high‑visibility pedestrian exclus...

Discover moreForklift Side Spotter – Red LED Safety Zone Light | 1200 Lumens | IP67 | CSA/MOL Visual Zone | Brampton ON

- Dimensions

- 7.85 × 2.66 cm

- Light

- LED (100,000 hours)

- Light color

- Red

The Forklift Rear Spotter – Blue LED Safety Light provides a high‑visibility warning zone behind ...

Discover moreForklift Rear Spotter – Blue LED Safety Light | 830 Lumens | CSA/MOL Visual Zone | IP68 | Brampton ON

- Dimensions

- 5.61 × 4.72 cm

- Light

- LED (50,000 hours)

- Light color

- Blue

The Forklift Front Spotter – White LED Safety Beam provides a high‑visibility forward warning zon...

Discover moreForklift Front Spotter – White LED Safety Beam | 1500 Lumens | IP68 | 360° Bracket Mount | CSA Visual Zone | Brampton ON

- Dimensions

- 2.5 × 5 × 5.75 cm

- Light color

- White

- Rated

- 1500 Lumens

Material: Dense impact‑absorbing polymer | Dimensions: 18 in L × 4 in W × 1.5 in thick | Weight: 10 kg

Discover moreSafe‑Bump Forklift Protectors | Magnetic Cushion Guards | Prevent Damage | Wrap‑Around Design | Brampton ON

- Material

- Dense impact‑absorbing polymer

- Dimensions

- 18 in L × 4 in W × 1.5 in thick

- Weight

- 10 kg

The Access Supply RR‑FS‑50‑OR 3‑Legged Safety Fence System is a modular visual‑zone barrier desig...

Discover moreAccess Supply RR‑FS‑50‑OR – 3‑Legged Safety Fence System | 50′ Raised Orange Barrier | Lockout Zone Kit | CSA Visual Zone | Brampton ON

- (skidded shipping weight

- 207 lbs.)

- System Type

- 3‑Legged Safety Barrier Kit

- Kit Includes

- (1) Orange fence cartridge (50′) • (4) Orange posts with lockout ends • (4) Rubber post bases • (1) Steel cartridge base • (1) Post carry bag

When overhead access is needed but space is tight, the Roll‑A‑Fold Safety Ladder delivers. This 7...

Discover moreRoll-A-Fold Safety Ladder – 7-Step Folding Warehouse Ladder | Perforated Tread | CSA-Ready Access Tool | Brampton ON

- Weight

- 218 kg

- Dimensions

- 6 × 2 × 6 ft

- Step Count

- 7 steps

The CMH‑95 Rubber Wheel Chock Set is a heavy‑duty restraint system engineered for CSA‑compliant t...

Discover moreCMH-95 Rubber Wheel Chock Set | Welded Steel Handle, Chain & Sign | CSA Dock Safety | Brampton ON

- Material

- 80‑durometer molded rubber

- Handle

- Welded steel carry/retrieval handle

- Chain

- Galvanized safety chain (prevents chock separation)

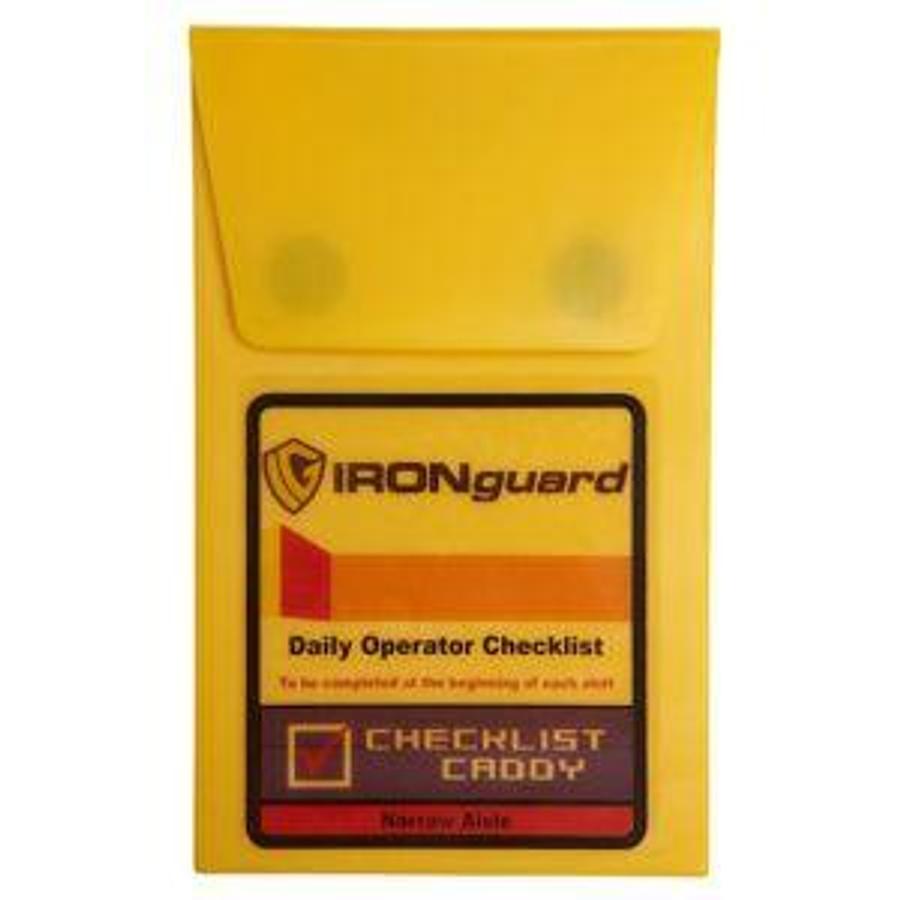

This Checklist Caddy restores CSA/MOL‑compliant inspection capability for electric counterbalance...

Discover moreChecklist Caddy – Electric Counterbalance Forklift | CSA/MOL Daily Inspection Kit | 75-Sheet Log Pad | Peel-and-Stick Envelope | Brampton ON

- Weight

- 2.2 lb

- Pad

- 75‑sheet carbonless daily inspection log

- Envelope Size

- 4.5 in × 7 in

This Replacement Checklist Pad is designed for forklift‑mounted checklist caddy systems and suppo...

Discover moreReplacement Checklist Pad – 75-Sheet Carbon-Copy Log | CSA/MOL Pre-Shift Inspection | Fits Checklist Caddy System | Brampton ON

- Weight

- 2.2 lb

- Type

- Replacement inspection checklist pad

- Pages

- • 75 carbon‑copy sheets • Dual‑entry format (operator copy + internal record)

This Replacement Checklist Caddy provides a complete CSA/MOL‑aligned inspection solution for skid...

Discover moreReplacement Checklist Caddy – Skid Steer Mount | CSA/MOL Pre-Use Safety Log | 75-Sheet Inspection Pad | Peel & Stick Mount | Brampton ON

- Weight

- 2.2 lb

- Fitment

- Skid steers • Mini‑loaders • Compact utility machines

- Includes

- 75‑sheet carbon‑copy daily checklist pad • 4.5 in × 7 in polyethylene envelope (cold‑ and weather‑resistant) • Pen with tether (optional add‑on)

This Checklist Caddy restores CSA/MOL‑compliant inspection capability for electric stackers, walk...

Discover moreChecklist Caddy – Electric Stacker | CSA/MOL Daily Inspection Kit | 75-Sheet Log Pad | Peel-and-Stick Envelope | Brampton ON

- Weight

- 2.2 lb

- Fitment

- Electric pallet stackers • Walkie riders • Compact lift trucks

- Contents

- 75‑sheet carbon‑copy checklist pad • 4.5 in × 7 in polyethylene envelope (weather‑ and cold‑resistant) • Pen with tether (optional add‑on)

This Replacement Checklist Caddy restores CSA/MOL‑aligned daily inspection capability for electri...

Discover moreReplacement Checklist Caddy – Electric Pallet Truck | CSA/MOL Daily Inspection Pad | 75-Sheet Log | Peel & Stick Envelope | Brampton ON

- Weight

- 2.2 lb

- Fitment

- • Electric pallet trucks • Walkies

- Includes

- 75‑sheet carbon‑copy checklist pad • Polyethylene envelope – 4.5 in × 7 in • Pen with tether (optional add‑on)

This Replacement Checklist Caddy restores CSA/MOL‑aligned pre‑shift inspection capability for ele...

Discover moreReplacement Checklist Caddy – Electric Narrow Aisle Forklift | CSA/MOL Inspection Pad | 75-Sheet Log | Peel & Stick Mount | Brampton ON

- Weight

- 2.2 lb

- Contents

- 75‑sheet carbon‑copy inspection pad • Polyethylene checklist envelope (4.5 in × 7 in) • Pen with tether (optional add‑on)

- Fitment

- Electric narrow aisle forklifts • Reach trucks • Swing‑mast units • Turret trucks

This Replacement Checklist Caddy is engineered for crane operators performing daily pre‑use inspe...

Discover moreReplacement Checklist Caddy – Crane | CSA/MOL Pre-Use Inspection Kit | 75-Sheet Log Pad | Cold-Resistant Envelope | Brampton ON

- Weight

- 2.2 lb

- Fitment

- Overhead cranes • Mobile cranes • Tower cranes

- Includes

- • 75‑sheet carbonless inspection pad • 4.5 in × 7 in polyethylene envelope (cold‑ and moisture‑resistant) • Pen with tether (optional add‑on)

This Replacement Checklist Caddy is engineered for aerial work platforms (AWPs) including scissor...

Discover moreReplacement Checklist Caddy – Aerial Work Platform | CSA/MOL Pre-Use Inspection Kit | 75-Sheet Log Pad | Peel & Stick Mount | Brampton ON

- Weight

- 2.2 lb

- Fitment

- • Scissor lifts • Boom lifts • Vertical mast lifts • All CSA/MOL‑regulated AWPs

- Includes

- 75‑sheet carbon‑copy inspection pad • 4.5 in × 7 in polyethylene envelope (cold‑ and weather‑resistant) • Pen with tether (optional add‑on)

The RapidRoll Outdoor Portable Barrier System is a high‑visibility, fast‑deploy fencing solution ...

Discover moreRapidRoll Outdoor Portable Barrier System | 50′ Wheeled Fence Kit | Lockout Safety Zone | CSA Visual Zone | Brampton ON

- System Type

- Wheeled safety barrier kit Kit Includes: • (1) Wheeled base unit with integrated fence cartridge • (1) 50′ orange raised‑profile safety fence • (4) Orange posts with lockout ends • (4) Rubber post bases

- Fence Material

- Flexible raised‑profile barrier (orange)

- Overall size

- 22 deep X 31 wide X 64 high

The Forklift Battery Spill Kit is a wall‑mounted acid‑response station engineered for CSA/MOL‑reg...

Discover moreForklift Battery Spill Kit | Acid Neutralizer Station | CSA Safety | Brampton ON

- Mounting

- Wall‑mounted spill‑response station

- Kit Includes

- Acid neutralizer • Neoprene gloves • Safety goggles • Face shield • Acid‑resistant apron • Absorbent pads / cleanup tools • High‑visibility wall‑mount board

- Compliance

- CSA/MOL & WHMIS‑aligned spill‑response components

The Honeywell Fendall Pure Flow 1000 delivers 15 minutes of uninterrupted, pH‑balanced saline flu...

Discover moreHoneywell Pure Flow 1000 Eyewash Station | Wall-Mount | CSA Safety | Brampton ON

- Standard(s) Met

- ANSI Z358.1

- Activation

- Sure‑grip pull handle with expiration strap

- Solution

- 15‑minute continuous flow of pH‑balanced Eyesaline®

These Propane Cylinder Handling Gloves provide on‑the‑spot protection for technicians and operato...

Discover morePropane Cylinder Handling Gloves | Forklift-Mounted PPE Kit | CSA LP Safety | Brampton ON

- Mounting

- Forklift‑mountable | Retractable holster system

- Glove Dimensions

- 24.6 cm × 22.9 cm × 14 cm

- Material

- Heat‑ and liquid‑resistant textile compound

The Portable Safety Zone Indoor Barrier System is designed for CSA/MOL‑regulated visual‑zone cont...

Discover morePortable Safety Zone – Indoor Barrier System | 50′ Slimline Fence Kit | Magnetic Clips | Roll‑Away Wheeled Base | CSA Visual Zone | Brampton ON

- System Type

- Portable Indoor Barrier – Slimline Fence Kit

- Components Included

- • Orange posts with magnetic clips • Roll‑away wheeled base • 50′ slimline fencing • Magnetic or freestanding mounting

- Mobility

- Wheeled base for indoor repositioning

When forklift zones shift, your safety system needs to move with them. The Portable Safety Zone L...

Discover morePortable Safety Zone LED Light Package | Kit of 5 | Waterproof | Field‑Mount | CSA/MOL Visual Zone | Brampton ON

- Kit Includes

- • (5) waterproof LED safety lights • Field‑mount hardware or magnetic bases (model‑dependent)

- Power

- Battery‑powered

- Runtime

- Up to ~200 hours continuous

The SC‑8 Aluminum Wheel Chock Set is a lightweight, high‑grip dock‑safety solution designed for t...

Discover moreSC‑8 Aluminum Wheel Chock Set | Lightweight Dock Safety | CSA‑Ready | Brampton ON

- Dimensions

- 7 in W × 11.5 in L × 8 in H

- Material

- Corrosion‑resistant aluminum

- Weight

- 6 lb per chock | 28 lb full set

Blind corners and congested aisles increase collision risk in busy warehouse environments. The Wi...

Discover moreWide Magnetic Forklift Mirror | 180° Dome View | CSA/MOL Operator Awareness | Fast Install | Brampton ON

- Mirror Style

- Dome‑style safety mirror

- Field of View

- 180° wide‑angle visibility

- Mounting Options

- Magnetic arm (included) • Peel‑and‑stick tape (optional)

Blind spots and tight turns increase collision risk in busy warehouse environments. The Magnetic ...

Discover moreMagnetic Side Mirror – Wide‑Angle Forklift Safety Mirror | 180° View | Fast Magnetic Mount | For Reverse Travel | Brampton ON

- Type

- Forklift safety mirror – magnetic side mount

- Field of View

- 180° panoramic coverage

- Mounting Options

- Magnetic arm (included) • Optional peel‑and‑stick tape (not included)

Reverse travel puts strain on operators and increases the risk of unsafe overhead‑guard grabs. Th...

Discover moreErgo Back‑Up Handle with Horn | Forklift Reverse Travel Safety | CSA/MOL Operator Ergonomics | Brampton ON

- Handle Type

- Ergonomic reverse‑travel handle with integrated horn button

- Mounting

- Overhead guard mount (hardware included)

- Material

- Impact‑resistant polymer

Blind spots are a leading cause of warehouse collisions. The 9″ Dome Forklift Mirror provides a f...

Discover more9″ Dome Forklift Mirror – 3M Tape Mount | 180° Safety View | Anti‑Blind Spot | Fast Install | Brampton ON

- Mirror Type

- Dome‑style safety mirror

- Size

- 9 in diameter

- Field of View

- 180° panoramic visibility

The MagTool™ Magnetic Tape Gun is a rugged, industrial‑grade dispenser designed for fast‑paced wa...

Discover moreMagTool™ Magnetic Tape Gun | 100 lb Magnetic Base | Industrial Dispenser for Forklifts & Steel Surfaces | Brampton ON

- Mount Style

- Rear‑mounted magnet (100 lb pull strength)

- Material

- Industrial‑grade red metal

- Dimensions

- 6 in W × 3 in H × 9.5 in L

The MagTool™ Box is a rugged magnetic organizer built for high‑traffic industrial environments wh...

Discover moreMagTool™ Box – Magnetic Tool Organizer | 100 lb Hold | No‑Drill Steel Mount | Forklift, Shop & Warehouse Use | Brampton ON

- Mounting Style

- Rear‑mounted 100 lb integrated magnet

- Material

- ndustrial‑grade polymer / ABS blend

- Dimensions

- tandard MagTool Box format

The DL60‑HDLED Dock Light is engineered for CSA‑regulated warehouses, food‑grade facilities, and ...

Discover moreDL60-HDLED Dock Light – 60″ Arm | Heavy-Duty LED | IP66 Rated | CSA Warehouse Safety Lighting | Brampton ON

- Weight

- 55 lb

- Voltage input

- 100-240VAC, 50/60Hz, Single Phase

- Reach

- 40 and 60 (1016mm and 1524mm)

The MagTool™ Magnetic Document Board keeps critical paperwork visible, secure, and accessible in ...

Discover moreMagTool™ Magnetic Document Board | 9″ × 13″ Steel‑Mount Organizer | Invoice, Packing Slip & Checklist Holder | Brampton ON

- Mount Style

- Built‑in rear magnet (steel‑surface adhesion)

- Material

- Reinforced plastic board with magnetic backing

- Size

- 9 in W × 13 in L

When a forklift is unsafe, this kit ensures it stays locked out until repairs are complete. The L...

Discover moreLockOut Guard Kit | Forklift LOTO System | Electric & Propane Disconnect | CSA/OSHA Compliant | Brampton ON

- Weight

- 1 kg

- Kit Contents

- LockOut Guard box • (4) CSA/OSHA safety tags • (4) Zip‑tie straps • (1) Keyed padlock

- Use Case

- Electric or propane forklift energy‑source lockout Compatibility: Battery connectors, LP tank brackets, service disconnects

When visibility is critical and compliance is non‑negotiable, the DL40‑HDLED delivers. Engineered...

Discover moreDL40-HDLED Dock Light – 40″ LED Arm | CSA/MOL-Compliant | IP66 Sealed | Food-Grade | Brampton ON

- Weight

- 55 lb

- The voltage input

- 100-240vac, 50/60Hz, single phase.

- Voltage input

- 100-240VAC, 50/60Hz, Single Phase

This CSA/MOL‑compliant Lift Truck Log Replacement Book is engineered for electric narrow‑aisle fo...

Discover moreLift Truck Log Replacement Book – Electric Narrow Aisle | 624 CSA Checklists | Repair & Incident Reporting | Lockout Tag Included | Brampton ON

- Weight

- 4.4 lb

- Fitment

- Electric narrow‑aisle forklifts, including: • Reach trucks • Order pickers

- Includes

- 624 Daily Checklist Forms • 24 Forklift Repair Request Forms • 4 Accident Report Forms • 4 Near‑Miss Report Forms • Lockout Tag (unsafe equipment status) • Preventive Maintenance Log – 36 Events

This CSA/MOL‑compliant Lift Truck Log Book is engineered for propane counterbalance forklifts and...

Discover moreLift Truck Log Book – CSA/MOL Compliant | 624 Checklists | Propane Counterbalance | Brampton ON

- Weight

- 4.4 lb

- Fitment

- Propane counterbalance forklifts

- Includes

- 624 CSA/MOL‑aligned daily inspection forms • Built‑in lockout tag for unsafe equipment • Repair request tracking • Accident and near‑miss documentation • Preventive maintenance logging

This CSA/MOL‑compliant Lift Truck Log Book is a complete inspection and documentation system for ...

Discover moreLift Truck Log Book – Replacement Inspection Kit | 2-Year CSA Safety Records | For Electric Counterbalance & IC Units | Brampton ON

- Weight

- 4.4 lb

- Pages

- 624 daily checklist entries

- Report Forms

- • 4 accident reports • 4 near‑miss reports • 24 repair request forms

This CSA/MOL‑compliant Lift Truck Log Book is engineered for internal combustion counterbalance f...

Discover moreLift Truck Log Replacement Book – Internal Combustion Counterbalance | 624 CSA Checklists | Repair & Incident Reporting | Lockout Tag Included | Brampton ONg

- Weight

- 4.4 lb

- Fitment

- Internal combustion counterbalance forklifts (propane, diesel, and gas‑powered units)

- Includes

- 624 Daily Pre‑Use Checklist Forms • 24 Forklift Repair Request Forms • 4 Accident Report Forms • 4 Near‑Miss Report Forms • Lockout Tag (for unsafe lift tagging) • Preventive Maintenance Log – 36 PM Entries

This CSA/MOL‑compliant Lift Truck Log Book is engineered for electric pallet trucks and walkies, ...

Discover moreLift Truck Log Replacement Book – Electric Pallet Truck | 624 CSA Checklists | Repair & Incident Reporting | Lockout Tag Included | Brampton ON

- Weight

- 4.4 lb

- Fitment

- Electric pallet trucks / walkies

- Includes

- • 624 Daily Pre‑Use Checklist Forms • 24 Repair Request Forms • 4 Accident Report Forms • 4 Near‑Miss Report Forms • Lockout Tag (for unsafe truck shutdown) • Preventive Maintenance Log – Tracks 36 PM Events

This CSA/MOL‑compliant Lift Truck Log Book is engineered for diesel counterbalance forklifts and ...

Discover moreLift Truck Log Replacement Book – Diesel Counterbalance | 624 CSA Checklists | Repairs, Incidents & PM Tracking | Lockout Tag Included | Brampton ON

- Weight

- 4.4 lb

- Fitment

- Diesel counterbalance forklifts

- Includes

- 624 Daily CSA/MOL Pre‑Use Checklist Forms • 24 Forklift Repair Request Forms • 4 Accident Report Forms • 4 Near‑Miss Report Forms • Lockout Tag (LOTO compliant) • Preventive Maintenance Log – Tracks 36 Events

This CSA/MOL‑compliant Lift Truck Log Book is purpose‑built for sit‑down electric counterbalance ...

Discover moreLift Truck Log Replacement Book – Sit-Down Electric Forklift | 624 CSA Checklists | Repairs, Incidents & PM Tracking | Lockout Tag Included | Brampton ON

- Weight

- 4.4 lb

- Fitment

- Sit‑down electric counterbalance forklifts

- Includes

- 624 Daily CSA/MOL Pre‑Use Checklist Forms • 24 Forklift Repair Request Forms • 4 Accident Report Forms • 4 Near‑Miss Report Forms • Lockout Tag (LOTO compliant) • Preventive Maintenance Log – Tracks 36 Events

The IC‑10 ICE CHOCK is a heavy‑duty steel wheel‑restraint system engineered to prevent vehicle mo...

Discover moreIC‑10 ICE CHOCK (Complete Set) | Serrated Steel Tire Chocks | CSA Yard Safety | Brampton ON

- Material

- Formed steel | Powder‑coated

- Bottom Grip

- Serrated metal teeth for ice/snow traction

- Fitment

- Tires up to 22.5R

This CSA/MOL‑compliant Lift Truck Log Book is engineered for electric counterbalance forklifts an...

Discover moreLift Truck Log Replacement Book – Electric Counterbalance | 624 CSA Checklists | Repairs, Incidents & PM Tracking | Lockout Tag Included | Brampton ON

- Weight

- 4.4 lb

- Fitment

- Electric counterbalance forklifts

- Includes

- 624 Daily CSA/MOL‑aligned checklist forms • 24 Repair request forms • 4 Accident report forms • 4 Near‑miss report forms • Built‑in lockout tag (unsafe equipment tagging) • Preventive maintenance tracking (36 events)

The DLGN‑120‑PLED Gooseneck LED Dock Light is engineered for CSA‑regulated trailer bays, workstat...

Discover moreDLGN-120-PLED Gooseneck LED Dock Light | 27″ Arm | CSA/MOL-Compliant | Impact-Resistant Head | UL/cUL Certified | Brampton ON

- Weight

- 55 lb

- Arm

- 27 in stainless steel gooseneck • 180° rotation • Anti‑sag, cold‑weather resistant

- Elbow

- Steel conduit elbow • Directional positioning for precise aiming

When dock visibility matters and vibration is constant, this light holds its shape. The DLGN‑L1 L...

Discover moreDLGN-L1 LED Dock Light | 27″ Stainless Gooseneck Arm | CSA/MOL-Compliant | UL/cUL Certified | Brampton ON

- Weight

- 55 lb

- Arm

- • 27 in stainless steel flex conduit • 180° rotation • Anti‑sag, cold‑weather resistant

- Light Head

- Polycarbonate housing • Impact‑ and heat‑resistant • Vented dome • Wire guard

The EZ3 MagTool Kit is a compact magnetic tool system engineered for fast‑paced warehouse, dock, ...

Discover moreEZ3 MagTool Kit – Magnetic Clipboard, Tape Gun & Box Cutter Set | 100 lb Magnet | Dockside & Warehouse Utility | Brampton ON

- Kit Includes

- MagTool Clipboard – 100 lb magnet • MagTool Tape Gun – magnetic base • MagTool Utility Cutter – magnetic mount

- Mounting Surface

- Steel racking, dock doors, carts, workstations

- Availability

- Purchase | Rental | Lease‑to‑Own (OAC)

When dock visibility matters and vibration is constant, this light holds its shape. The DLGN‑120 ...

Discover moreDLGN-120 Dock Light | 60″ Stainless Gooseneck Arm | CSA/MOL-Compliant Task Lamp | UL/cUL Certified | Brampton ON

- Weight

- 55 lb

- Mounting Arm

- • 60 in stainless steel gooseneck • Holds shape under vibration • Wraps around dock doors and track hardware

- Lamp Head

- • UV‑stabilized polycarbonate shell • Impact‑resistant • Cool‑touch design

Kit Includes: Neoprene gloves • Safety goggles • Face shield • Acid‑resistant apron • Flashlight • Battery...

Discover moreForklift Battery PPE Kit | CSA-Compliant Wall Mount Station | Brampton ON

- Kit Includes

- Neoprene gloves • Safety goggles • Face shield • Acid‑resistant apron • Flashlight • Battery hydrometer • Wall‑mount safety board

- Fitment

- Indoor battery‑charging stations | Wall‑mount bracket required

- Weight

- 6 kg

When a workplace injury happens, seconds matter—and so does compliance. This Level 3 First Aid Ki...

Discover moreFirst Aid Kit – Level 3 BC-Compliant Pouch | 48-Unit Capacity | Soft-Sided | MOL/CSA Ready | Brampton ON

- Province/Federal Compliance

- British Columbia OHS

- CSA Standard

- CSA Z1220‑17

- Kit Leve

- Level 3

The Bright‑Belt™ Forklift Safety Restraint makes operator compliance visible from anywhere on the...

Discover moreBright‑Belt™ Forklift Safety Restraint | 60″ High‑Visibility Buckle System | Operator Compliance Upgrade | Brampton ON

- Belt Length

- 60 in (high‑visibility orange)

- Material

- Industrial‑grade webbing with heavy‑duty buckle

- Mount Style

- Bolt‑on clamp to overhead guard or rear support

The Ergo Back‑Up Handle – Hardwired with Horn gives operators a safe, ergonomic grip point during...

Discover moreErgo Back‑Up Handle – Hardwired with Horn | Forklift Reverse Travel Safety | Reduces Strain & Hand Injury | Brampton ON

- Mounting Position

- Interior overhead guard or rear post

- Handle Style

- Ergonomic grip with integrated horn button

- Horn Connection

- Hardwired to forklift horn circuit (wiring required)

When your dock operates in hazardous zones, lighting isn’t optional — it’s compliance. The DLXLED...

Discover moreDLXLED-SP Explosion-Proof Dock Spotlight | CSA/MOL-Compliant | IP66 | Dual-Beam LED | Hazardous Location Certified | Brampton ON

- Weight

- 61.7 lb

- Rating

- Explosion‑proof — Zone 1 / Division 1 equivalent

- Ingress Protection

- IP66 sealed (wet, washdown, and outdoor‑rated)

The DLFAN40 Dock Fan delivers high‑output, CSA/MOL‑aligned ventilation for trailer bays, dock doo...

Discover moreDLFAN40 Dock Fan – 18″ Blade | 40″ Arm | CSA/MOL-Compliant Ventilation | IRONguard Compatible | Brampton ON

- Weight

- 66 lb

- Fan Diameter

- 18 in low‑vibration blade

- Airflow

- Moves up to 3,000+ CFM

The DLWB Heavy Duty Arm Bracket Kit is a rugged, corrosion‑resistant mounting solution engineered...

Discover moreDLWB Heavy Duty Arm Bracket Kit | Forklift Accessory Mount | CSA/MOL Retrofit | Corrosion-Resistant | Brampton ON

- Weight

- 17.6 lb

- Material

- • Heavy‑gauge metal • Corrosion‑resistant • Paintable finish • Burr‑free edges

- Mount Style

- Bolt‑on (hardware not included) • Weld‑on

When your dock operates in hazardous zones, lighting isn’t optional—it’s compliance. The DLXLED‑F...

Discover moreDLXLED-FL Explosion-Proof Floodlight | Hazardous Location LED Dock Light | CSA/MOL-Compliant | IP66 | UL/cUL Certified | Brampton ON

- Rating

- Explosion‑proof | Hazardous & wet‑location approved

- Lighting Type

- LED | Long‑life | Low‑maintenance

- Optics

- Spotlight and floodlight versions available

The DLFAN60 Dock Fan is engineered for CSA‑regulated warehouse zones, trailer docks, and high‑tra...

Discover moreDLFAN60 Dock Fan – 60″ Articulating Arm | CSA/MOL-Compliant Cooling | IRONguard Compatible | Brampton ON

- Weight

- 77 lb

- Arm Length

- 60 in articulating steel arm

- Fan Head

- 18 in polycarbonate housing

The Dissipator Battery Cap (Exide‑Compatible) is a high‑performance upgrade for industrial lead‑a...

Discover moreDissipator Battery Cap | Exide-Compatible | CSA Battery Safety | Brampton ON

- Fitment

- Exide & compatible industrial lead‑acid batteries

- Functionality

- Recycles up to 80% of evaporated water • Instant electrolyte‑level detection via “magic eye” • Reduces watering intervals and acid splash

- Design

- Ergonomic twist‑off cap

The Dissipator Battery Cap (Yellow) is a rugged, high‑efficiency upgrade for industrial lead‑acid...

Discover moreDissipator Battery Cap (Yellow) | Ergonomic Twist-Off | CSA Battery Bay Safety | Brampton ON

- Type

- High‑retention acid cap with vapor‑recovery system

- Material

- Acid‑resistant, impact‑resistant polymer

- Fitment

- Universal for most industrial lead‑acid batteries

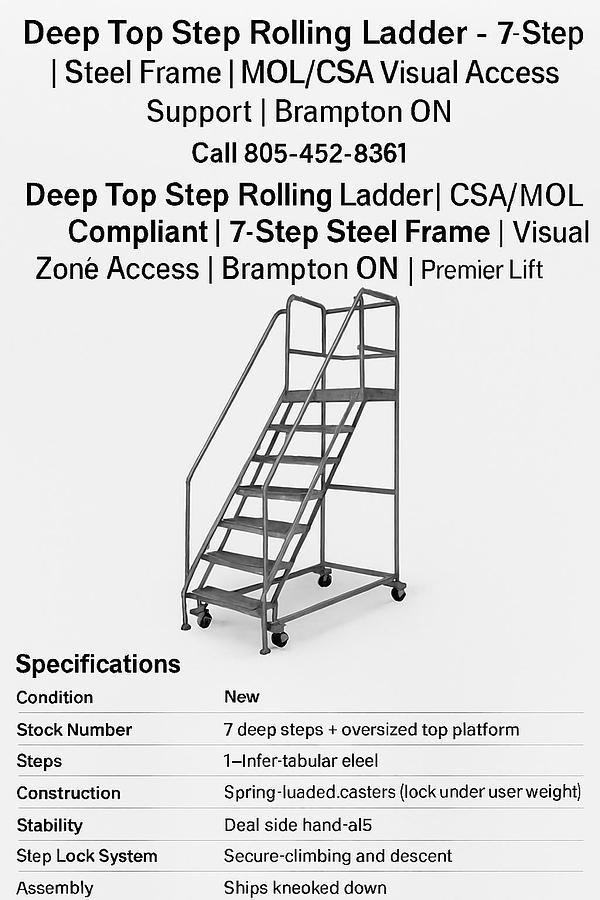

When elevated access is required, this Deep Top Step Rolling Ladder delivers. Built with a 7‑step...

Discover moreDeep Top Step Rolling Ladder – 7-Step | Steel Frame | MOL/CSA Visual Access Support | Brampton ON

- Step Dimensions

- 16‑13/16″ wide × 7″ deep, spaced 10″ apart

- Base Width × Depth

- 30″ W × 59″ D

- Platform Width

- 18″

When dock temperatures spike, airflow becomes a safety requirement—not a convenience. The DLFAN40...

Discover moreDLFAN40 Dock Fan with 40″ Arm | CSA/MOL-Compliant Ventilation | IRONguard Compatible | Brampton ON

- Fan Diameter

- 18 in high‑output, 3‑speed

- Mounting Arm

- 40 in seven‑gauge steel wall bracket

- Airflow

- 3,000+ CFM

This combination emergency shower and eyewash station is engineered for fast response in hazardou...

Discover moreEmergency Shower & Eyewash Station | CSA/ANSI Compliant | Brampton ON

- Coverage area

- Eye/Face

- Installation type

- Pedestal/Shower

- Bowl material

- Plastic

The Checklist Caddy – Skid Steer / Forklift Inspection Log Kit is a CSA/MOL‑compliant safety stat...

Discover moreChecklist Caddy – Skid Steer / Forklift Inspection Log Kit | 75‑Sheet CSA/MOL Safety Pad | Peel & Stick Envelope Mount | Brampton ON

- Weight

- 2 kg

- Fitment

- Forklifts, skid steers, telehandlers, pallet trucks, aerial lifts

- Kit Contents

- • 75‑sheet dual‑copy inspection pad • Wire‑attached ballpoint pen • 4.5 in × 7 in poly envelope with peel‑and‑stick mount

The CMH‑94 Rubber Wheel Chock is a rugged, high‑traction restraint designed to secure forklifts, ...

Discover moreCMH‑94 Rubber Wheel Chock | One‑Piece Molded | CSA Dock Safety | Brampton ON

- Material

- Solid rubber (80 durometer – high grip and durability)

- Colour

- Black (tire‑grade rubber compound)

- Handle

- Built‑in molded rubber handle

The Checklist Caddy – Propane Counterbalance Forklifts is a complete CSA/MOL‑compliant inspection...

Discover moreChecklist Caddy – Propane Counterbalance Forklifts | Pre‑Use Daily Inspection Kit | Includes 75‑Page Log Pad, Pen & Mountable Envelope | Brampton ON

- Weight

- 2 kg

- Language

- English

- Fitment

- Propane counterbalance forklifts

The Checklist Caddy – Electric Pallet Truck (Walkie) | French Edition is a CSA/MOL‑compliant insp...

Discover moreChecklist Caddy – Electric Pallet Truck (Walkie) | French Edition | CSA/MOL Daily Inspection Kit | Includes Log Pad, Pen & Mountable Envelope | Brampton ON

- Weight

- 2 kg

- Language

- French

- Fitment

- Electric pallet trucks – walkie, rider, center control

The Checklist Caddy – Electric Stacker is a CSA/MOL‑compliant inspection station designed for wal...

Discover moreChecklist Caddy – Electric Stacker | Pre‑Use Safety Inspection Kit | 75‑Sheet Log Pad | CSA/MOL Compliant | Brampton ON

- Weight

- 2 kg

- Language

- English

- Fitment

- Electric stackers – walkie, rider, compact lift trucks

The Checklist Caddy – Electric Pallet Truck is a CSA/MOL‑compliant inspection station designed fo...

Discover moreChecklist Caddy – Electric Pallet Truck | CSA/MOL Daily Inspection Kit | 75‑Sheet Log Pad | Peel‑and‑Stick Mount | Brampton ON

- Weight

- 2 kg

- Language

- English

- Fitment

- Electric pallet trucks – walkies, riders, center riders

The Checklist Caddy – Electric Narrow Aisle Forklifts (French Edition) is a CSA/MOL‑compliant ins...

Discover moreChecklist Caddy – Electric Narrow Aisle Forklifts | French Edition | CSA/MOL Inspection Station | Log Pad, Pen & Mountable Envelope | Brampton ON

- Weight

- 2 kg

- Language

- French

- Fitment

- Electric narrow aisle forklifts – reach trucks, order pickers, stand‑up lifts

The Checklist Caddy – Electric Narrow Aisle Forklifts is a compact, high‑visibility CSA/MOL‑compl...

Discover moreChecklist Caddy – Electric Narrow Aisle Forklifts | CSA/MOL Inspection Station | 75‑Sheet Log Pad | Peel‑and‑Stick Mount | Brampton ON

- Weight

- 2 kg

- Language

- English

- Fitment

- Electric narrow aisle forklifts (reach trucks, order pickers, stand‑up lifts)

The Checklist Caddy – Forklift Daily Inspection Kit is an all‑in‑one CSA/MOL‑compliant documentat...

Discover moreChecklist Caddy – Forklift Daily Inspection Kit | CSA/MOL Safety Log Pad | Peel & Stick Mount | Brampton ON

- Weight

- 2 kg

- Envelope Size

- 4.5 in × 7 in

- Mount Type

- Peel‑and‑stick adhesive (two‑way tape)

The Checklist Caddy – Electric Counterbalance (French Edition) is a CSA/MOL‑compliant inspection ...

Discover moreChecklist Caddy – Electric Counterbalance | French Edition | CSA/MOL Inspection Compliance | Brampton ON

- Weight

- 2 kg

- Language

- French

- Fitment

- Electric counterbalance forklifts

The Checklist Caddy – Overhead Crane is a CSA/MOL‑compliant pre‑use inspection station designed t...

Discover moreChecklist Caddy – Overhead Crane | Pre‑Use Inspection Station | 75‑Sheet Log Pad | CSA Safety Compliant | Brampton ON

- Weight

- 2 kg

- Language

- English

- Includes

- Polyethylene mountable envelope (4.5 in × 7 in) • 75‑sheet carbon‑copy checklist pad • Pen with tether wire

The Checklist Caddy – Aerial Work Platform is a CSA/MOL‑compliant pre‑use inspection station desi...

Discover moreChecklist Caddy – Aerial Work Platform | Pre‑Use Inspection Station | 75‑Sheet Log Pad | CSA Safety Compliant | Brampton ON

- Weight

- 2 kg

- Fitment

- Aerial work platforms – scissor lifts, boom lifts, vertical masts

- Includes

- • Polyethylene envelope (4.5 in × 7 in) with two‑way mounting tape • 75‑sheet carbon‑copy inspection pad • Pen with attached plastic wire Mounting: Peel‑and‑stick (included)

The Checklist Caddy – Aerial Work Platform (French Version) is a CSA/MOL‑compliant inspection sta...

Discover moreChecklist Caddy – Aerial Work Platform | French Version | CSA/MOL Inspection Compliance | Brampton ON

- Weight

- 2 kg

- Language

- French

- Fitment

- Aerial work platforms – scissor lifts, boom lifts, vertical masts

The CBI‑29 Cast Iron Wheel Chock is a heavy‑duty restraint block designed to secure lift trucks, ...

Discover moreCBI‑29 Cast Iron Wheel Chock – Reversible | 8″ × 12″ × 9″ | CSA Dock Safety | Brampton ON

- Material

- Ductile cast iron

- Dimensions

- 12 × 8 × 9 cm

- Fitment

- Tires up to 22.5R

The CBI‑087 Cast Ductile Iron Wheel Chock Set provides reliable immobilization for trailers, lift...

Discover moreCBI‑087 Cast Iron Wheel Chock Set | Dock Safety | CSA‑Ready | Brampton ON

- Material

- Cast ductile iron – impact and fatigue resistant

- Colour

- Safety yellow – corrosion‑resistant finish

- Dimensions (each)

- 8‑1/4 in W × 7‑1/4 in L × 8‑1/2 in H

When elevated tasks demand safety, this Forklift Safety Cage delivers. Designed for maintenance, ...

Discover moreForklift Safety Cage – CSA-Compliant Work Platform | 48″ × 48″ | Fall Protection & Elevated Task Access | Brampton ON

- Platform Size

- 48″ × 48″

- Construction

- Reinforced steel mesh panels

- Gate

- Locking swing gate

When uptime depends on safe hydration, this gun delivers. Engineered for industrial lead‑acid for...

Discover moreBattery Watering Gun | Auto Shut-Off | CSA Forklift Safety

- Weight

- 2 kg

- Mounting

- Handheld | Hose‑fed | Compatible with most battery watering systems

- Trigger Type

- Ergonomic front grip

The 88‑8XL Laminated Wheel Chock Set is a heavy‑duty dock‑safety solution built from compressed l...

Discover more88‑8XL Laminated Wheel Chock – Complete Set | 14″ × 11.25″ × 14″ | 72 lb | CSA Dock Safety | Brampton ON

- Dimensions

- 14 × 11.25 × 14 cm

- Weight

- 72 kg

- Material

- Compressed recycled truck tires

The Accu‑Tilt™ Fork Level Indicator gives operators a clear, real‑time visual reference of fork t...

Discover moreAccu‑Tilt Fork Level Indicator | Universal Fork Tilt Reference | Installs in 2 Minutes | Prevents Rack & Pallet Damage

- Mount Type

- Adhesive (tool‑free installation)

- Visibility

- Universal tilt reference viewable from operator’s seat

- Compatibility

- All sit‑down counterbalance forklifts

The Back‑SavR™ Stand‑Up Forklift Guard provides rear‑impact protection for operators working in t...

Discover moreBack‑SavR Stand‑Up Forklift Guard | Operator Collision Protection | Knuffi Impact Padding | CSA/MOL Retrofit | Brampton ON

- Length

- 53 in

- Profile

- 2.5 in W × 2.5 in H square tube

- Construction

- Powder‑coated black steel

The CMH‑95 Rubber Wheel Chock is a heavy‑duty restraint block molded from solid 80‑durometer rubb...

Discover moreCMH‑95 Rubber Wheel Chock | Steel Handle | CSA Dock Safety | Brampton ON

- Material

- Laminated rubber from recycled truck tires

- Reinforcements

- Galvanized steel side plates

- Dimensions

- 14 × 11.25 × 14 cm