Advanced Filters

Category

Subcategory

Manufacturer

Condition

Lowered Mast Height

Raised Mast Height

Capacity

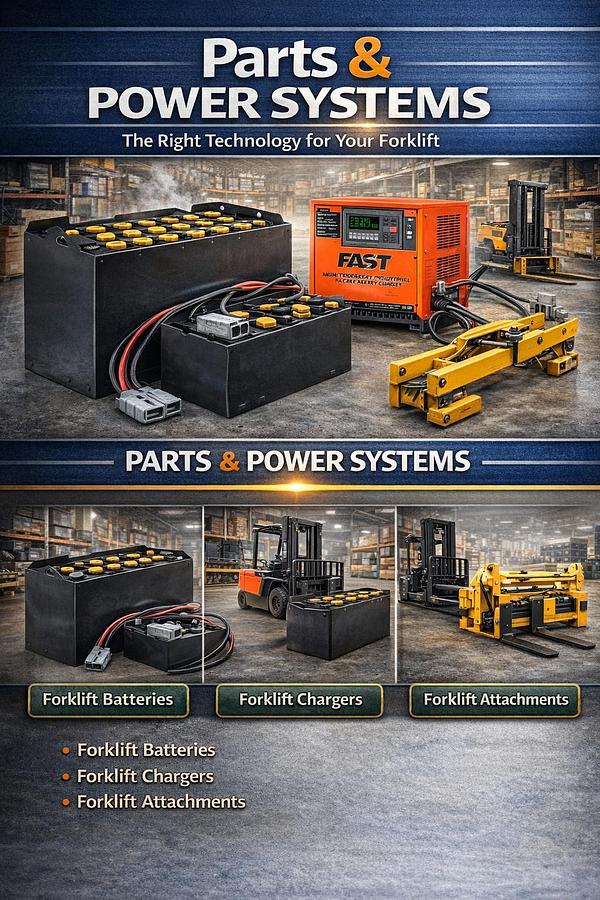

Premier Lift Equipment provides a complete range of forklift parts and power‑system components fo...

Discover moreParts & Power Systems – Forklift Parts & Components

- Category Overview

- This page represents our Parts & Power Systems master category. Use it to compare replacement components, electrical systems, hydraulic parts, drive‑line assemblies, and wear items that support safe, reliable operation of electric and internal‑combustion forklifts across warehouse, manufacturing, dock, and outdoor environments. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of parts are included in this category? This category covers electrical components, hydraulic systems, drive motors, controllers, filters, hoses, cylinders, mast components, batteries, chargers, and other service‑critical forklift parts. Are these parts compatible with all forklift brands? Yes. We supply components for most major manufacturers, including electric, LP, diesel, and gasoline forklifts. How do I confirm part compatibility? Provide your forklift’s model and serial number. We verify fitment, specifications, and any required sub‑components before supplying parts. Do you offer OEM and aftermarket options? Yes. OEM‑grade and high‑quality aftermarket parts are available depending on customer preference and availability. Do you provide new, used, or refurbished components? Yes. Many parts are available in new, used, or refurbished condition, all inspected and verified for performance. Do you offer installation or service support? Yes. Premier Lift Equipment provides diagnostics, repairs, inspections, and installation services for all parts sold. Can parts affect forklift safety or performance? Yes. Worn or incorrect components can reduce lifting capacity, cause electrical faults, create hydraulic leaks, or compromise safe operation. Do you ship parts across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Equipment Types

- Electric Forklifts · IC Forklifts · Reach Trucks · Order Pickers · Walkies · Tow Tractors · Aerial Lifts

Forklift batteries provide the power foundation for electric warehouse equipment, including reach...

Discover moreForklift Batteries – Lithium‑Ion, Lead‑Acid & AGM (New & Refurbished)

- Category Overview

- This page represents our Parts & Power Systems category for forklift batteries. Use it to compare lithium‑ion, lead‑acid, and AGM industrial battery options across 24V, 36V, 48V, and 80V configurations for electric forklifts, reach trucks, order pickers, walkies, and stackers. All units support CSA‑aligned operation and are available in new or refurbished condition. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of forklift batteries are available? This category includes lithium‑ion, lead‑acid (flooded), and AGM industrial batteries for electric forklifts and warehouse equipment. What voltage options do you supply? We offer 24V, 36V, 48V, and 80V batteries to support reach trucks, order pickers, walkies, stackers, and sit‑down electrics. Are these batteries CSA‑ready? Yes. All batteries can be delivered CSA‑ready with UL/cUL documentation and inspection reports for facility compliance. Do you supply new and refurbished batteries? Yes. We offer new and refurbished units, all load‑tested and verified for compatibility with your equipment. What are the advantages of lithium‑ion forklift batteries? Lithium‑ion batteries provide fast charging, zero maintenance, longer lifespan, and multi‑shift performance for high‑demand warehouse operations. Can these batteries be used in cold‑storage environments? Yes. Cold‑storage‑rated lithium‑ion and AGM options are available for low‑temperature and freezer applications. Do you provide battery health reports or testing? Yes. Load‑testing, inspection reports, and battery health documentation are available upon request. Do you supply compatible chargers? Yes. Standard, fast‑charge, and opportunity‑charge compatible chargers are available to match your battery type and operational requirements. Can you confirm compatibility with my forklift? Yes. Provide your model number, serial number, and voltage requirements, and we will verify correct fitment. Do you ship forklift batteries across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Supported Equipment

- Electric Forklifts • Reach Trucks • Order Pickers • Walkies • Stackers

Forklift attachments expand a lift truck’s capabilities for specialized material handling, includ...

Discover moreForklift Attachments – Clamps, Forks, Booms & Specialty Tools

- Category Overview

- This page represents our Material Handling Attachments category. Use it to compare attachment types, mounting classes, hydraulic requirements, and application‑specific solutions designed to expand the capabilities of electric and internal‑combustion forklifts in warehouse, manufacturing, dock, and outdoor environments. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of forklift attachments are available? This category includes sideshifters, fork positioners, clamps, rotators, carton clamps, paper roll clamps, push‑pulls, booms, extensions, and other specialized handling tools. How do I determine if an attachment fits my forklift? Fitment depends on carriage class, hydraulic function availability, weight capacity, and the forklift’s model and serial number. We verify compatibility before supplying any attachment. Do attachments affect lifting capacity? Yes. Every attachment has a rated weight and center‑of‑gravity impact. The forklift’s capacity plate must be updated to reflect the attachment’s weight and load center. Are hydraulic functions required for certain attachments? Yes. Clamps, rotators, fork positioners, and push‑pulls require one or more auxiliary hydraulic functions. We can confirm requirements based on your forklift’s configuration. Do you offer both new and used attachments? Yes. We supply new, used, and refurbished attachments depending on availability and customer needs. Can attachments improve productivity? Yes. Attachments allow forklifts to handle specific materials more efficiently, reduce manual handling, and improve workflow in specialized applications. Do you provide installation or service support? Yes. Premier Lift Equipment offers installation, hydraulic setup, inspections, and service for all attachment types. Do you ship attachments across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Compliance Standards

- CSA B335 · MOL Protocols · Hydraulic Integration Standards · Load‑Capacity Recalculation · Audit‑Ready Documentation

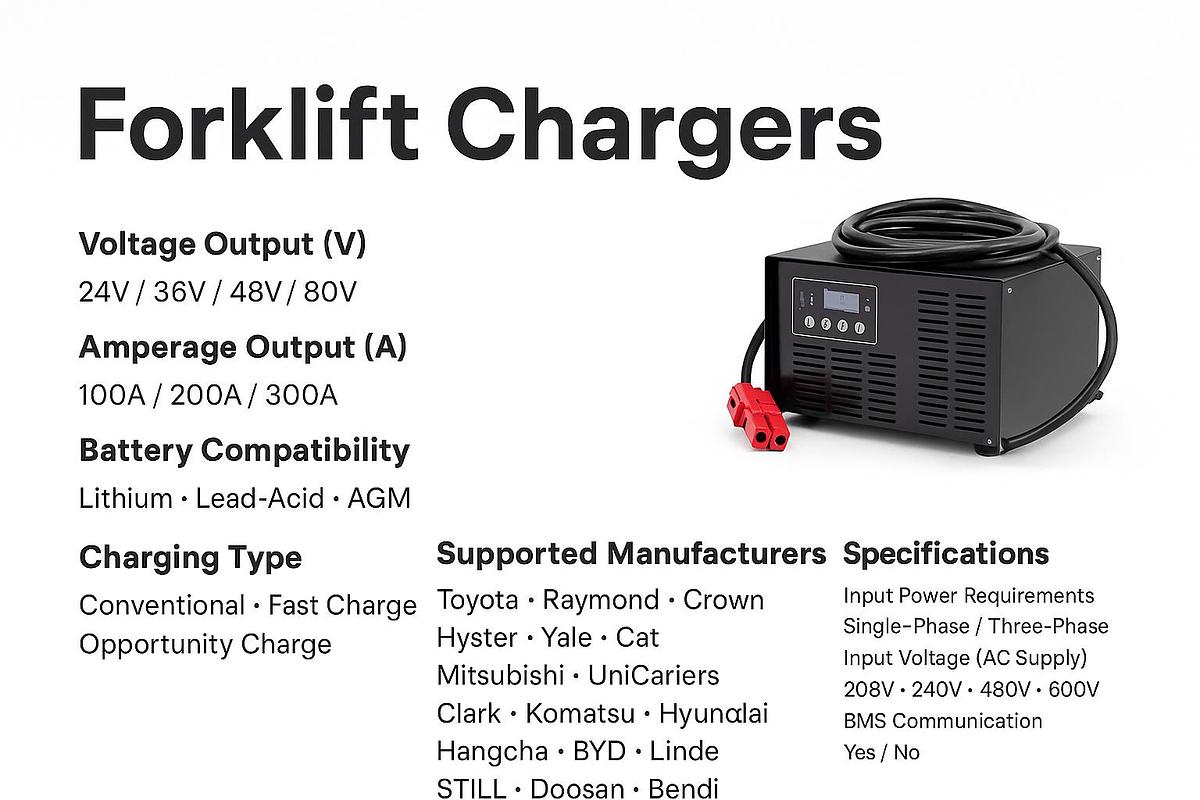

Forklift battery chargers provide controlled DC power for lithium‑ion, AGM, and lead‑acid industr...

Discover moreForklift Battery Chargers – 24V, 36V, 48V & 80V (Lithium, AGM & Lead‑Acid)

- Category Overview

- This page represents our Parts & Power Systems category for forklift battery chargers. Use it to compare voltage outputs, charging profiles, connector types, and compatibility across lithium‑ion, AGM, and lead‑acid industrial batteries used in warehouse, manufacturing, 3PL, and multi‑shift operations. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What voltage outputs are available? Chargers are available in 24V, 36V, 48V, and 80V configurations to support all major electric forklift platforms. Are these chargers compatible with lithium‑ion batteries? Yes. Lithium‑ion smart chargers with BMS communication and multi‑stage charging profiles are available. What charging types do these units support? Options include conventional overnight charging, fast‑charge systems, and opportunity‑charge workflows for high‑cycle environments. How do I determine the correct charger for my forklift? Provide your forklift’s model, battery voltage, amp‑hour rating, and connector type. We verify compatibility with your battery chemistry and facility power requirements. What input voltages are supported? Chargers can be configured for 208V, 240V, 480V, or 600V, in single‑phase or three‑phase setups. Are these chargers CSA‑ready? Yes. All chargers can be delivered CSA‑ready with UL/cUL documentation and safety compliance support. What connector types are available? Common options include SB50, SB175, SB350, and DIN connectors. Do you offer new, used, and refurbished chargers? Yes. Units are available in new, used, and refurbished configurations, all load‑tested and verified for performance. Do you ship chargers across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Charging Types

- Conventional • Fast Charge • Opportunity Charge

This high‑quality electrical component is engineered for reliable performance across all major fo...

Discover moreElectrical Controllers, Contactors & Drive Motors

- Category Overview

- This page represents our Parts & Power Systems category for electrical controllers, contactors, and drive motors. Use it to compare control modules, power‑distribution components, traction motors, and electrical assemblies used in electric forklifts and warehouse equipment. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of electrical components do you supply for forklifts? We supply traction controllers, pump controllers, drive motors, contactors, relays, sensors, wiring assemblies, and other electrical system components for all major forklift brands. Are these components compatible with my forklift model? Yes. Provide your model number, serial number, and voltage system (24V/36V/48V/80V). We verify compatibility before purchase to ensure correct operation and safe installation. Do you offer new, used, or refurbished electrical components? We offer new OEM‑grade components, high‑quality aftermarket options, and select refurbished units depending on availability and customer requirements. Can you help diagnose electrical issues before ordering parts? Yes. We can help identify likely failure points based on symptoms such as error codes, loss of traction, intermittent power, hydraulic slowdown, or contactor chatter. Are these components CSA‑ready? Yes. All electrical components can be supplied with CSA‑ready documentation, inspection reports, and compliance support for facility audits. Do you supply AC and DC drive motors? Yes. We offer both AC and DC drive motors for electric forklifts, including traction motors, pump motors, and steer motors. Do controllers need programming or calibration after installation? Many controllers require programming, parameter setup, or BMS communication checks. We can guide you through the requirements or connect you with certified technicians. Do you ship electrical components across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Part Type

- Controller / Contactor / Drive Motor

This high‑quality mast component is engineered for reliable performance across all major forklift...

Discover moreMast Rollers, Lift Chains & Sheaves

- Category Overview

- This page represents our Parts & Power Systems category for mast rollers, lift chains, and sheaves. Use it to compare roller types, chain sizes, sheave assemblies, and wear‑related mast components required to maintain smooth lifting, tilting, and load‑handling performance on electric and internal‑combustion forklifts. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What mast components do you supply for forklifts? We supply mast rollers, load rollers, chain rollers, lift chains, sheaves, guide bearings, and related mast‑assembly components for all major forklift brands. How do I know which rollers or chains fit my forklift? Provide your forklift’s model number, serial number, and mast type (2‑stage, 3‑stage, 4‑stage). We verify compatibility before purchase to ensure correct fitment and safe operation. Do you offer OEM, aftermarket, or refurbished mast components? Yes. We offer OEM‑grade components, high‑quality aftermarket options, and select refurbished parts depending on availability and customer requirements. When should mast rollers or lift chains be replaced? Rollers should be replaced when they show flat‑spotting, binding, or excessive wear. Lift chains should be replaced when elongation exceeds 2–3%, when rust or corrosion is present, or when a facility audit requires updated components. Are these components CSA‑ready? Yes. All mast components can be supplied with CSA‑ready documentation, inspection reports, and compliance support for facility audits. Do you supply complete mast‑rebuild kits? Yes. Full kits including rollers, chains, sheaves, bearings, and hardware are available for most common mast configurations. Can you help diagnose mast issues before ordering parts? Yes. We can help identify likely failure points based on symptoms such as binding during lift, uneven mast travel, chain popping, or roller noise under load. Do you ship mast components across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Part Type

- Mast Roller / Lift Chain / Sheave

This high‑quality hydraulic component is engineered for reliable performance across all major for...

Discover moreHydraulic Hoses, Pumps & Cylinders

- Category Overview

- This page represents our Parts & Power Systems category for hydraulic hoses, pumps, and cylinders. Use it to compare hose types, pump assemblies, lift cylinders, seal kits, and hydraulic components required for maintaining safe and reliable forklift mast, steering, and auxiliary hydraulic functions. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What hydraulic components do you supply for forklifts? We supply hydraulic hoses, fittings, lift cylinders, tilt cylinders, steering cylinders, hydraulic pumps, valves, and seal kits for all major forklift brands. How do I confirm which hose or cylinder fits my forklift? Provide your forklift’s model number, serial number, and mast type. We verify hose length, fitting type, cylinder dimensions, and pump compatibility before purchase. Do you offer OEM, aftermarket, or rebuilt hydraulic components? Yes. We offer OEM‑grade hoses and cylinders, high‑quality aftermarket options, and professionally rebuilt cylinders and pumps depending on availability. When should hydraulic hoses or cylinders be replaced? Hoses should be replaced when cracking, bulging, or leaks appear. Cylinders should be replaced or rebuilt when drifting, slow lift, seal failure, or visible scoring occurs. Are these hydraulic components CSA‑ready? Yes. All hydraulic components can be supplied with CSA‑ready documentation, inspection reports, and compliance support for facility audits. Do you supply complete hydraulic rebuild kits? Yes. Full seal kits, gland kits, and rebuild kits are available for most lift, tilt, and steering cylinders. Can you help diagnose hydraulic issues before ordering parts? Yes. We can help identify likely failure points based on symptoms such as slow lifting, mast drift, pump noise, overheating, or hydraulic fluid loss. Do you ship hydraulic components across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Part Type

- Hydraulic Hose / Pump / Cylinder

This high‑quality replacement component is engineered for reliable performance across all major f...

Discover moreForklift Forks & Carriage Components

- Category Overview

- This page represents our Parts & Power Systems category for forklift forks and carriage components. Use it to compare fork sizes, carriage classes, mounting types, and wear‑related components for electric and internal‑combustion forklifts operating in warehouse, manufacturing, dock, and outdoor environments. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of forks and carriage components do you supply? We supply standard ITA forks, shaft‑mounted forks, fork bars, fork positioners, carriage rollers, load backrests, and related carriage‑assembly components for all major forklift brands. How do I confirm which forks fit my forklift? Provide your forklift’s model number, serial number, carriage class (Class II, III, IV), and fork length/width requirements. We verify compatibility before purchase to ensure correct fitment and safe operation. Do you offer new, used, or refurbished forks? Yes. We offer new OEM‑grade forks, high‑quality aftermarket options, and select refurbished forks depending on availability and customer requirements. When should forklift forks be replaced? Forks should be replaced when heel wear exceeds 10%, when cracks or bends are present, or when a facility audit requires updated forks for CSA/MOL compliance. Are these forks and carriage components CSA‑ready? Yes. All forks and carriage components can be supplied with CSA‑ready documentation, inspection reports, and compliance support for facility audits. Do you supply fork positioners and side‑shift components? Yes. We supply fork positioners, side‑shift assemblies, rollers, and hardware for most common carriage configurations. Can you help diagnose carriage issues before ordering parts? Yes. We can help identify likely failure points based on symptoms such as uneven fork height, difficulty side‑shifting, roller binding, or excessive carriage play. Do you ship forks and carriage components across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Part Type

- Forks / Carriage Component

This high‑quality replacement part is engineered for reliable performance across all major forkli...

Discover moreForklift Tires & Wheels

- Category Overview

- This page represents our Parts & Power Systems category for forklift tires and wheels. Use it to compare tire types, wheel assemblies, compounds, and fitment options for electric and internal‑combustion forklifts operating in warehouse, manufacturing, dock, and cold‑storage environments. For additional details, see the Frequently Asked Questions (FAQ) tab.

- Frequently Asked Questions (FAQ)

- What types of forklift tires and wheels do you supply? We supply pneumatic tires, solid pneumatic tires, cushion tires, non‑marking tires, press‑on tires, load wheels, steer wheels, and complete wheel assemblies for all major forklift brands. How do I know which tire type is right for my forklift? Provide your forklift’s model number, serial number, and operating environment. We confirm the correct tire type (cushion, pneumatic, solid, non‑marking) and wheel size for safe, compliant operation. Do you offer new, used, or remolded forklift tires? Yes. We offer new OEM‑grade tires, high‑quality aftermarket options, and select remolded or refurbished tires depending on availability and customer requirements. When should forklift tires be replaced? Tires should be replaced when wear reaches the safety line, when chunking or cracking appears, when flat spots develop, or when traction and stability are compromised. Are non‑marking tires available for food, pharma, or clean‑floor environments? Yes. We supply non‑marking cushion and solid tires designed for clean‑floor, food‑grade, pharmaceutical, and cold‑storage applications. Do you supply press‑on tires and wheel assemblies? Yes. We offer press‑on tires, bonded assemblies, and complete wheel replacements for electric forklifts, walkies, pallet jacks, and reach trucks. Can you help diagnose tire or stability issues before ordering? Yes. We can help identify likely issues based on symptoms such as vibration, uneven wear, reduced traction, steering difficulty, or stability concerns under load. Do you ship forklift tires and wheels across Canada and the United States? Yes. We ship nationwide across Canada and the U.S., with local delivery options available in the GTA and surrounding regions.

- Part Type

- Forklift Tire / Wheel

The Jamco EP4803 is a new, CSA‑certified 48V high‑frequency smart charger engineered for 685–850 ...

Discover moreJamco EP4803 | 48V Forklift Battery Charger | 80A Output | 208–240V Single‑Phase | CSA Certified | New

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 80A

- Battery Compatibility

- Lead‑Acid (LA), AGM, Gel

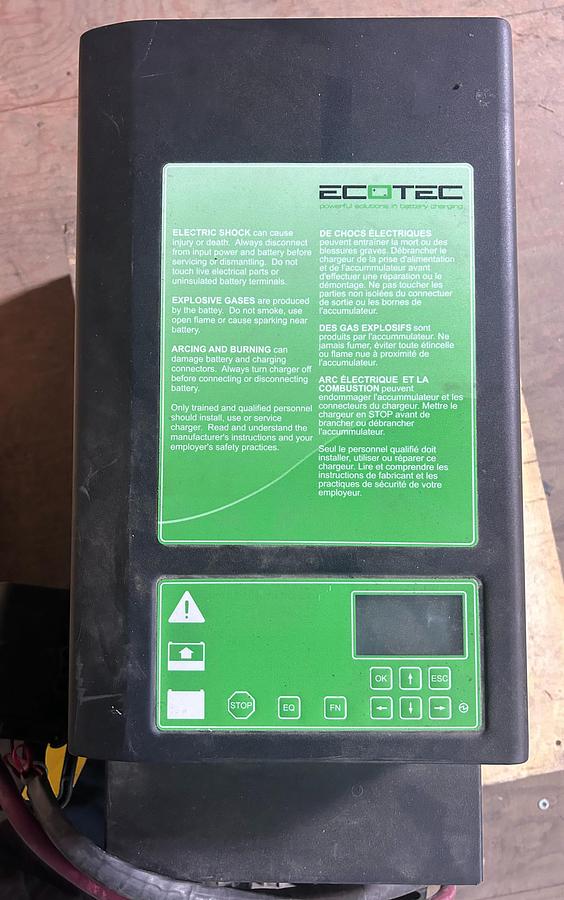

The ECOTEC ACCESS 20/80 is a high‑output 80V industrial forklift battery charger engineered for 4...

Discover more80 Volt 1000–1200 Amp Hour | ECOTEC ACCESS 20/80 | USA‑Compatible Forklift Battery Charger | 200A Output | 480V 3‑Phase | UL Certified

- Part Number

- 80‑800‑320OC

- Voltage Output (V)

- 80V

- Amperage Output (A)

- 200A

The Power Designers LMT‑10kW‑48‑250T is a high‑output 48V industrial forklift battery charger eng...

Discover more48 Volt 1000–1200 Amp Hour | Power Designers LMT‑10kW‑48‑250T | USA‑Compatible Forklift Battery Charger | 250A Output | 480V 3‑Phase | UL Certified

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 250A

- Battery Compatibility

- Flooded Lead‑Acid, AGM, Gel

The Power Designers LMT‑10kW‑48‑250T is a high‑output 48V industrial forklift battery charger eng...

Discover more48 Volt 1000–1200 Amp Hour | Power Designers LMT‑10kW‑48‑250T | USA‑Compatible Forklift Battery Charger | 250A Output | 480V 3‑Phase | UL Certified

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 250A

- Battery Compatibility

- Flooded Lead‑Acid, AGM, Gel

The Power Designers LMT‑10kW‑48‑250T is a high‑output 48V industrial forklift battery charger eng...

Discover more48 Volt 1000–1200 Amp Hour | Power Designers LMT‑10kW‑48‑250T | USA‑Compatible Forklift Battery Charger | 250A Output | 480V 3‑Phase | UL Certified

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 250A

- Battery Compatibility

- Lead‑Acid (Flooded), AGM, Gel

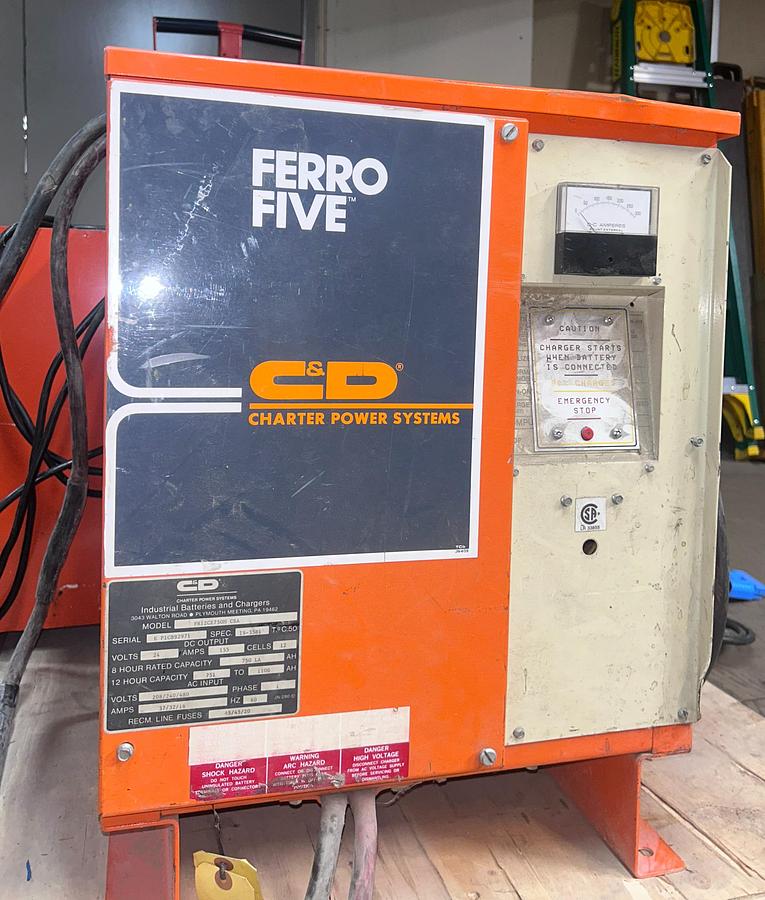

The C&D FR12C2ET750I is a high‑capacity 24V industrial forklift battery charger designed for 12‑c...

Discover more24V Industrial Forklift Battery Charger | C&D FR12C2ET750I CSA | CSA Certified

- Part Number

- IS‑3981

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 155A

This heavy‑duty 24V industrial forklift battery charger is engineered for 12‑cell lead‑acid, AGM,...

Discover more24 Volt 750–1000 Amp Hour | Smart Industrial Forklift Battery Charger | 120A–140A Output | High‑Frequency | CSA Certified

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 200A–240A

- Battery Compatibility

- Lead‑Acid (LA), AGM, Gel

This 24V high‑frequency smart forklift battery charger is engineered for 12‑cell lead‑acid batter...

Discover more24 Volt 600–750 Amp Hour | Smart Industrial Forklift Battery Charger | 100A Output | High‑Frequency | Multi‑Voltage Input | CSA Certified

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 100A

- Battery Compatibility

- Lead‑Acid (LA), 12 Cells

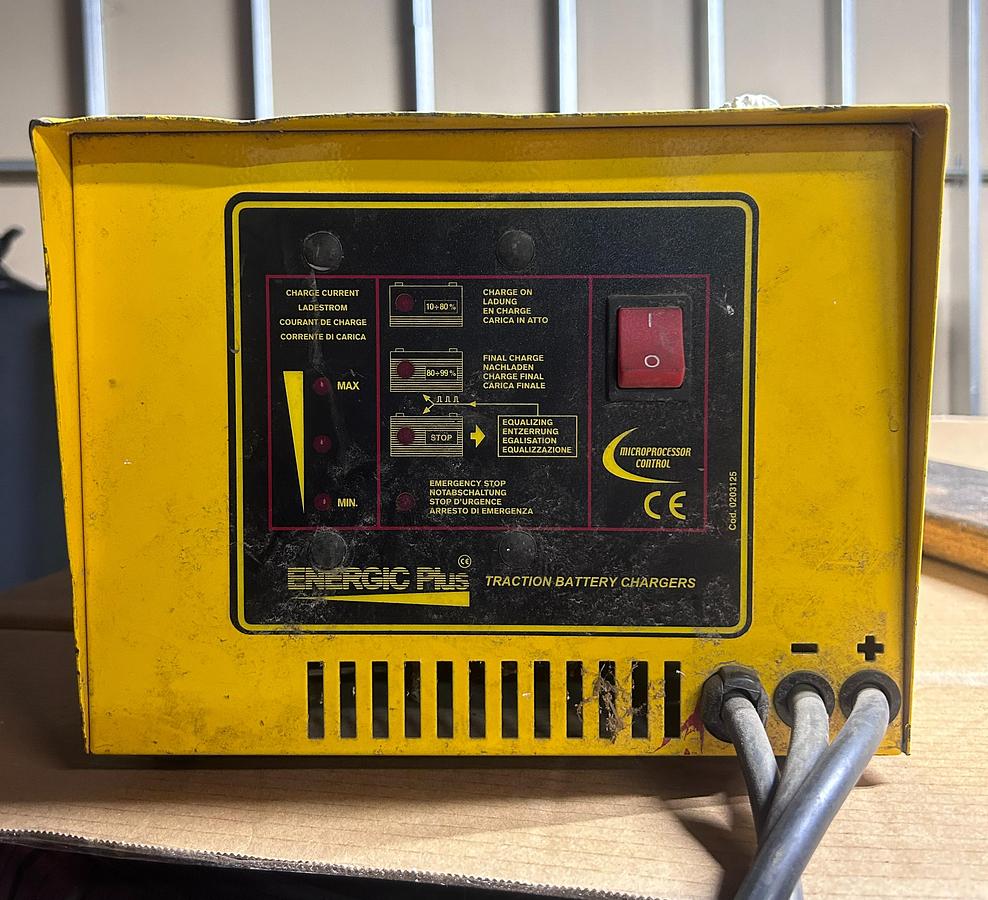

The Energic Plus TSS 48/10 is a compact 48V industrial forklift battery charger designed for 24‑c...

Discover more48 Volt 150 Amp Hour | Energic Plus TSS 48/10 | Industrial Forklift Battery Charger | 10A Output | 120V Single‑Phase | CSA Certified

- Part Number

- REC 213139

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 10A

The Yale 3YTN12‑775 is a heavy‑duty 24V industrial forklift battery charger designed for 12‑cell ...

Discover more24 Volt 775 Amp Hour | Yale 3YTN12‑775 | Industrial Forklift Battery Charger | 153A Output | 208/480V 3‑Phase | UL Certified

- Part Number

- U.S. Patent 4045717

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 153A

The Bassi EMVP124‑48‑240 is a versatile multi‑volt industrial forklift battery charger designed f...

Discover moreMulti‑Volt Forklift Battery Charger | Bassi EMVP124‑48‑240 | 12V–48V | 50A Output | 240V Single‑Phase | CSA & CE Certified

- Part Number

- CCM 2400

- Voltage Output (V)

- 12V / 24V / 36V / 48V

- Amperage Output (A)

- 50A

The Bassi Bruno SR2400 is a compact 36V industrial forklift battery charger designed for 18‑cell ...

Discover more36 Volt 700 Amp Hour | Bassi Bruno SR2400 | Industrial Forklift Battery Charger | 50A Output | 240V Single‑Phase | CSA & CE Certified

- Voltage Output (V)

- 36V

- Amperage Output (A)

- 50A

- Battery Compatibility

- Lead‑Acid (LA), 18 Cells

The C&D 18H1050E3 is a high‑capacity 36V industrial forklift battery charger designed for 10‑cell...

Discover more36 Volt 1050 Amp Hour | C&D 18H1050E3 | Industrial Forklift Battery Charger | 106A Output | 208/240/480V Single‑Phase | UL Certified

- Voltage Output (V)

- 36V

- Amperage Output (A)

- 106A

- Battery Compatibility

- Lead‑Acid (LA), 10 Cells

The MS1R‑1050B3 1E‑6 is a high‑capacity 24V industrial forklift battery charger engineered for 12...

Discover more24 Volt 1050 Amp Hour | MS1R‑1050B3 1E‑6 | Industrial Forklift Battery Charger | 240A Output | 208/240/480V 3‑Phase | UL Certified

- Part Number

- Spec 4574

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 240A

The Vulcan A2T24 60F8 is a compact 24V industrial forklift battery charger designed for 12‑cell l...

Discover more24 Volt 600 Amp Hour | Vulcan A2T24 60F8 | Industrial Forklift Battery Charger | 60A Output | 230V Single‑Phase | UL Certified

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 60A

- Battery Compatibility

- Lead‑Acid (LA), 12 Cells

The GNB 24‑GTD‑770‑XD‑1‑FK is a heavy‑duty 48V industrial forklift battery charger designed for 2...

Discover more48 Volt 770 Amp Hour | GNB 24‑GTD‑770‑XD‑1‑FK | Industrial Forklift Battery Charger | 105A Output | 600V 3‑Phase | UL Certified

- Part Number

- T‑535A

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 105A

This refurbished Cascade 40D Rotator is engineered for operations requiring fast, controlled, and...

Discover moreRefurbished Cascade 40D Rotator | 4,000 lb | 360° Continuous Rotation | 42” Forks | Class II | CSA/MOL Certified

- Rotation

- 360° Continuous Rotation

- * Fork Length

- 42"

- Mounting

- ITA Class II

The Bassi Bruno SR4603‑MT112 is a high‑capacity 24V industrial forklift battery charger designed ...

Discover more24 Volt 840–1000 Amp Hour | Bassi Bruno SR4603‑MT112 | Industrial Forklift Battery Charger | 140A Output | 208/480V 3‑Phase | CSA & CE Certified

- Part Number

- AE24.483/3/140.840

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 140A

The C&D FR12CET750I is a high‑capacity 24V industrial forklift battery charger designed for 12‑ce...

Discover more24 Volt 1100 Amp Hour | C&D FR12CET750I | Industrial Forklift Battery Charger | 155A Output | 208/240/480V Single‑Phase | CSA‑Certified

- Part Number

- ES3‑12‑680B

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 109A

The GNB SCR100‑12‑865T1 is a heavy‑duty 24V industrial forklift battery charger designed for 12‑c...

Discover more24 Volt 865 Amp Hour | GNB SCR100‑12‑865T1 | Industrial Forklift Battery Charger | 134A Output | 480V 3‑Phase | UL Certified

- Part Number

- V1C‑81‑32‑01

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 134A

The XTPL12‑600W3 EXT‑F is a multi‑circuit 12V industrial forklift battery charger designed for 6‑...

Discover more12 Volt 600 Amp Hour | XTPL12‑600W3 EXT‑F | Industrial Forklift Battery Charger | 3‑Circuit 50A Output | 208V 3‑Phase | UL Listed

- Part Number

- 35VDC

- Voltage Output (V)

- 12V

- Amperage Output (A)

- 50A per circuit

The 24‑85‑25 is a new 48V flooded lead‑acid industrial forklift battery designed for wide‑compart...

Discover more48V Forklift Battery | 24‑85‑25 | 680Ah Flooded Lead‑Acid | New • UL/CSA Compliant • Wide‑Tray Fit • 60‑Month Warranty

- Category Overview Summary

- New 48V flooded lead‑acid forklift battery with 680Ah capacity. Wide‑tray 25 fit, UL/CSA compliant, ideal for Mitsubishi, UniCarriers, Clark, and wide‑compartment 48V sit‑down forklifts.

- Category Overview Title

- New 48V Forklift Battery | 680Ah | Wide‑Tray 25 Fit

- Battery Type

- Lead‑Acid (Flooded)

The 24‑125‑21 is a new high‑capacity 48V flooded lead‑acid industrial forklift battery engineered...

Discover more48V Forklift Battery | 24‑125‑21 | High‑Capacity 1000Ah | New • UL/CSA Compliant • 60‑Month Warranty

- Category Overview Summary

- New 48V flooded lead‑acid forklift battery with a high‑capacity 125‑plate 1000Ah design. UL/CSA compliant and ideal for sit‑down electrics and multi‑shift warehouse operations.

- Category Overview Title

- New 48V Forklift Battery | 1000Ah | High‑Capacity 125‑Plate

- Battery Type

- Lead‑Acid (Flooded)

The 24‑85‑21 is a new 48V flooded lead‑acid industrial forklift battery engineered for sit‑down e...

Discover more48V Forklift Battery | 24‑85‑21 | 680Ah Flooded Lead‑Acid | New • UL/CSA Compliant • 60‑Month Warranty

- Category Overview Summary

- New 48V flooded lead‑acid forklift battery with 680Ah capacity. UL/CSA compliant and ideal for sit‑down electrics and high‑duty warehouse fleets.

- Category Overview Title

- New 48V Forklift Battery | 680Ah | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 18‑125‑17 is a new high‑capacity 36V flooded lead‑acid forklift battery engineered for reach ...

Discover more36V Forklift Battery | 18‑125‑17 | High‑Capacity 1000Ah | New • UL/CSA Compliant • 60‑Month Warranty

- Category Overview Summary

- New 36V flooded lead‑acid forklift battery with a high‑capacity 125‑plate 1000Ah design. UL/CSA compliant and ideal for reach trucks, stackers, and sit‑down forklifts.

- Category Overview Title

- New 36V Forklift Battery | 1000Ah | High‑Capacity 125‑Plate

- Battery Type

- Lead‑Acid (Flooded)

TThe 18‑85‑17 is a new 36V flooded lead‑acid industrial forklift battery engineered for reach tru...

Discover more36V Forklift Battery | 18‑85‑17 | 510Ah Flooded Lead‑Acid | New • UL/CSA Compliant • 60‑Month Warranty

- Category Overview Summary

- New 36V flooded lead‑acid forklift battery with 510Ah capacity. UL/CSA compliant and ideal for reach trucks, walkie stackers, and compact electric forklifts.

- Category Overview Title

- New 36V Forklift Battery | 510Ah | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 12‑100‑13 is a new high‑capacity 24V flooded lead‑acid forklift battery designed for walkie s...

Discover more24V Forklift Battery | 12‑100‑13 | High‑Capacity 100‑Plate | New • UL/CSA Compliant • 60‑Month Warrantyy

- Category Overview Summary

- New 24V flooded lead‑acid forklift battery with a high‑capacity 100‑plate design. UL/CSA compliant and ideal for walkies, stackers, and compact electric forklifts.

- Category Overview Title

- New 24V Forklift Battery | High‑Capacity 100‑Plate

- Battery Type

- Lead‑Acid (Flooded)

The 12‑125‑15 is a new high‑capacity 24V flooded lead‑acid forklift battery engineered for walkie...

Discover more24V Forklift Battery | 12‑125‑15 | High‑Capacity 125‑Plate | New • UL/CSA Compliant • 60‑Month Warranty

- Category Overview Summary

- New 24V flooded lead‑acid forklift battery with a high‑capacity 125‑plate design. UL/CSA compliant and ideal for walkies, stackers, and compact electric forklifts.

- Battery Type

- Lead‑Acid (Flooded)

- Voltage (V)

- 24V

The 12‑85‑13 is a new 24V flooded lead‑acid industrial forklift battery engineered for walkie sta...

Discover more24V Forklift Battery | 12‑85‑13 | 510Ah Flooded Lead‑Acid | New • UL/CSA Compliant • 60‑Month Warranty

- Category Overview Summary

- New 24V flooded lead‑acid forklift battery with 510Ah capacity. UL/CSA compliant and ideal for walkies, stackers, and compact electric forklifts.

- Category Overview Title

- New 24V Forklift Battery | 510Ah | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 12‑125‑17 is a high‑capacity reconditioned 24V industrial forklift battery designed for walki...

Discover more24V Forklift Battery | 12‑125‑17 | High‑Capacity 125‑Plate Class | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 24V lead‑acid forklift battery for walkie riders, walkie stackers, and compact electric forklifts. High‑capacity 125‑plate class, fully load‑tested and CSA‑ready.

- Category Overview Title

- 24V Forklift Battery | High‑Capacity | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 12‑100‑13 is a reconditioned 24V industrial forklift battery designed for walkie stackers, wa...

Discover more24V Forklift Battery | 12‑100‑13 | High‑Capacity 100‑Plate Class | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 24V lead‑acid forklift battery for walkie stackers, walkie riders, and compact electric forklifts. High‑capacity 100‑plate class, fully load‑tested and CSA‑ready.

- Category Overview Title

- 24V Forklift Battery | High‑Capacity | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 12‑85‑13 is a reconditioned 24V industrial forklift battery designed for walkie stackers, wal...

Discover more24V Forklift Battery | 12‑85‑13 | Standard Compartment Fit | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 24V lead‑acid forklift battery for walkie stackers, walkie riders, and compact electric forklifts. Standard‑fit tray, 85‑plate class capacity, fully load‑tested and CSA‑ready.

- Category Overview Title

- 24V Forklift Battery | Standard Fit | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The EnerSys EF3‑18‑1200 is a high‑capacity 36V industrial forklift battery charger designed for 1...

Discover more36 Volt 1200 Amp Hour | EnerSys EF3‑18‑1200 | Industrial Forklift Battery Charger | 216A Output | 480/550/600V 3‑Phase | UL & ISO Certified

- Part Number

- EF3‑18‑1200J

- Voltage Output (V)

- 36V

- Amperage Output (A)

- 216A

The EnerSys ES3‑18‑1200 is a heavy‑duty 36V industrial forklift battery charger built for high‑ca...

Discover more36 Volt 1200 Amp Hour | EnerSys ES3‑18‑1200 | Industrial Forklift Battery Charger | 192A Output | 480/550/600V 3‑Phase | UL & ISO Certified

- Part Number

- ES3‑18‑1200U

- Voltage Output (V)

- 36V

- Amperage Output (A)

- 192A

The 24‑125‑15 is a high‑capacity reconditioned 48V industrial forklift battery designed for elect...

Discover more48V Forklift Battery | 24‑125‑15 | High‑Capacity 125‑Plate Class | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 48V lead‑acid forklift battery for electric sit‑down forklifts and high‑demand warehouse fleets. High‑capacity 125‑plate class, fully load‑tested and CSA‑ready.

- Category Overview Title

- 48V Forklift Battery | High‑Capacity | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 24‑85‑19 is a reconditioned 48V industrial forklift battery designed for electric sit‑down fo...

Discover more48V Forklift Battery | 24‑85‑19 | Wide‑Compartment Fit | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 48V lead‑acid forklift battery for electric sit‑down forklifts and reach trucks. Wide‑compartment fit, 85‑plate class capacity, fully load‑tested and CSA‑ready.

- Category Overview Title

- 48V Forklift Battery | Wide‑Compartment | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 24‑85‑17 is a reconditioned 48V industrial forklift battery designed for electric sit‑down fo...

Discover more48V Forklift Battery | 24‑85‑17 | Wide‑Compartment Fit | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 48V lead‑acid forklift battery for electric sit‑down forklifts and reach trucks. Wide‑compartment fit, 85‑plate class capacity, fully load‑tested and CSA‑ready.

- Category Overview Title

- 48V Forklift Battery | Wide‑Compartment | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 24‑85‑21 is a reconditioned 48V industrial forklift battery designed for electric sit‑down fo...

Discover more48V Forklift Battery | 24‑85‑21 | Wide‑Compartment Fit | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 48V lead‑acid forklift battery for electric sit‑down forklifts and reach trucks. Wide‑compartment fit, 85‑plate class capacity, fully load‑tested and CSA‑ready.

- Category Overview Title

- 48V Forklift Battery | Wide‑Compartment | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 18‑125‑17 is a high‑capacity reconditioned 36V industrial forklift battery designed for elect...

Discover more36V Forklift Battery | 18‑125‑17 | Extra‑Wide Compartment | High‑Capacity 125‑Plate Class | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 36V lead‑acid forklift battery for electric sit‑down forklifts and reach trucks. Extra‑wide compartment fit, high‑capacity 125‑plate class, fully load‑tested and CSA‑ready.

- Category Overview Title

- 36V Forklift Battery | Extra‑Wide | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 18‑125‑15 is a reconditioned 36V industrial forklift battery designed for electric sit‑down f...

Discover more36V Forklift Battery | 18‑125‑15 | Wide‑Compartment Fit | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 36V lead‑acid forklift battery for electric sit‑down forklifts and reach trucks. Wide‑compartment fit, 125‑plate class capacity, fully load‑tested and CSA‑ready.

- Category Overview Title

- 36V Forklift Battery | Wide‑Compartment | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 18R‑125‑13 is a high‑capacity reconditioned 36V industrial forklift battery designed for reac...

Discover more36V Forklift Battery | 18R‑125‑13 | High‑Capacity 125‑Plate Class | Reconditioned • Load‑Tested • CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

- Voltage (V)

- 36V

- Capacity

- Equivalent to 125‑plate class (4.5‑hour rating)

The 18‑125‑11 is a reconditioned 36V industrial forklift battery designed for reach trucks, narro...

Discover more36V Forklift Battery | 18‑125‑11 | Narrow‑Compartment Fit | Reconditioned • Load‑Tested • CSA‑Ready

- Category Overview Summary

- Reconditioned 36V lead‑acid forklift battery for reach trucks and narrow‑compartment electrics. Narrow tray fit, 125‑plate class capacity, fully load‑tested and CSA‑ready.

- Category Overview Title

- 36V Forklift Battery | Narrow‑Compartment | CSA‑Ready

- Battery Type

- Lead‑Acid (Flooded)

The 12‑100‑13 is a reconditioned 24V industrial forklift battery designed for walkies, stackers, ...

Discover more24V Forklift Battery | 12‑100‑13 | Reconditioned • Load‑Tested • CSA‑Ready | Brampton ON

- Battery Type

- Lead‑Acid (Flooded)

- Voltage (V)

- 24V

- Capacity

- Equivalent to 100‑plate class (5.5‑hour rating)

The 12R‑85‑13 is a reconditioned 24V industrial forklift battery designed for walkies, stackers, ...

Discover more24V Forklift Battery | 12R‑85‑13 | Reconditioned • Load‑Tested • CSA‑Ready | Brampton ON

- Category Overview Summary

- Reconditioned 24V lead‑acid forklift battery for walkies and stackers. 85‑plate class capacity, fully load‑tested and CSA‑ready.

- Battery Type

- Lead‑Acid (Flooded)

- Voltage (V)

- 24V

The 12PP‑85G‑07 is a reconditioned 24V maintenance‑free forklift battery designed for walkies, wa...

Discover more24V Maintenance‑Free Forklift Battery | 12PP‑85G‑07 | Reconditioned | Built‑In 120V Charger | Brampton ON

- Condition Details

- Reconditioned • Load‑Tested • Maintenance‑Free

- Battery Type

- Lead‑Acid (Maintenance‑Free)

- Voltage(V)

- 24V

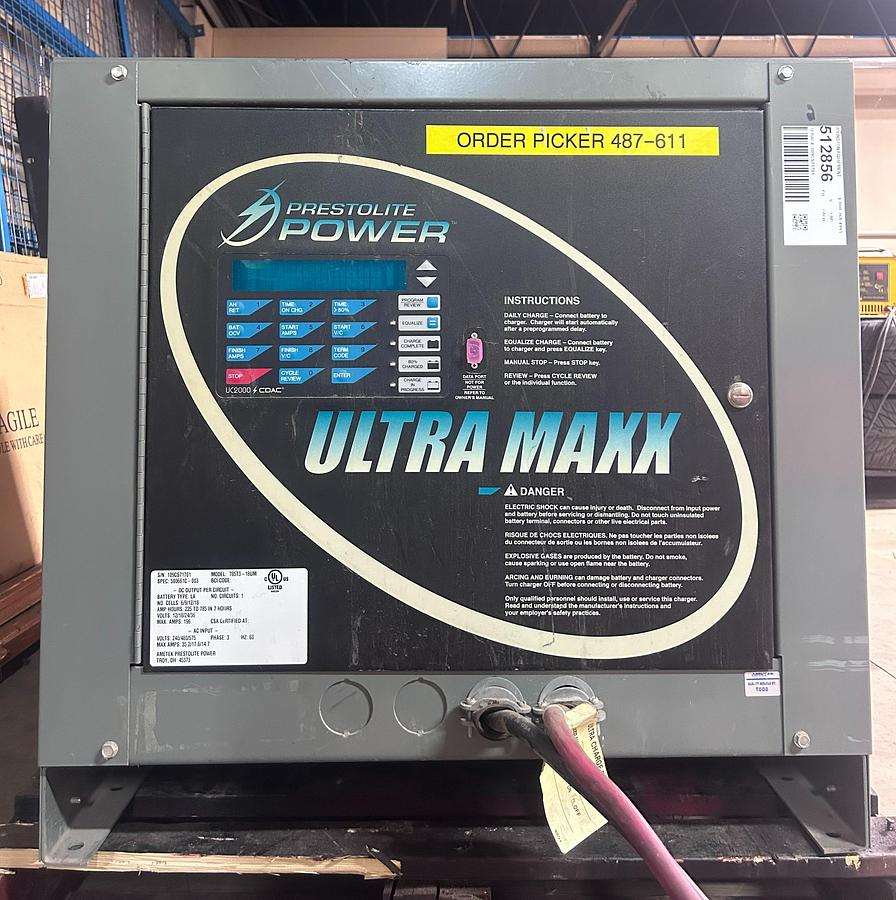

The Ametek Prestolite 786513‑18UM is a heavy‑duty 24V industrial forklift battery charger designe...

Discover more24 Volt 925 Amp Hour | Ametek Prestolite 786513‑18UM | Industrial Forklift Battery Charger | 228A Max Output | 208/480/575V 3‑Phase | CSA‑Certified

- Part Number

- 5006G771‑003

- Voltage Output (V)

- 24V

- Amperage Output (A)

- Up to 228A

The General Battery GCS‑24‑550 is a durable 48V industrial forklift battery charger designed for ...

Discover more48 Volt 550 Amp Hour | General Battery GCS‑24‑550 | Industrial Forklift Battery Charger | 83A Output | 208/230/460V 3‑Phase | UL & ISO Certified

- Part Number

- GCS‑24‑550J

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 83A

The C&D FR12CET750I is a high‑capacity 24V industrial forklift battery charger designed for 12‑ce...

Discover more24 Volt 1100 Amp Hour | C&D FR12CET750I | Industrial Forklift Battery Charger | 155A Output | 208/240/480V Single‑Phase | CSA‑Certified

- Part Number

- IS‑3981

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 155A

The Jamco SR 2400 is a durable 48V industrial forklift battery charger designed for 24‑cell lead‑...

Discover more48 Volt 100 Amp | Jamco SR 2400 | Industrial Forklift Battery Charger | 6.5 kVA | CSA & CE Certified | 210–250V Input

- Part Number

- 48/100

- Voltage Output (V)

- 48V

- Amperage Output (A)

- 100A

The GNB SGR100‑12‑475TJ is a compact 24V industrial forklift battery charger designed for 12‑cell...

Discover more24 Volt 475 Amp Hour | GNB SGR100‑12‑475TJ | Industrial Forklift Battery Charger | 208V 3‑Phase | CSA‑Ready

- Part Number

- 11‑78130‑03

- Voltage Output (V)

- 24V

- Amperage Output (A)

- Estimated ~100A (based on model prefix)

The Ametek Prestolite 91D73‑18UM is a high‑capacity 24V industrial forklift battery charger desig...

Discover more24 Volt 910 Amp Hour | Ametek Prestolite 91D73‑18UM | Industrial Forklift Battery Charger | 228A Output | 208/480/575V 3‑Phase | CSA‑Certified

- Part Number

- 500962C‑003

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 228A

The Staticon 90DLA24K94 is a compact 24V industrial forklift battery charger designed for 12‑cell...

Discover more24 Volt 140 Amp Hour | Staticon 90DLA24K94 | Industrial Forklift Battery Charger | 48.5A Output | 600V 3‑Phase | CSA‑Ready

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 48.5A

- Battery Compatibility

- Lead‑Acid (LA), 12 Cells

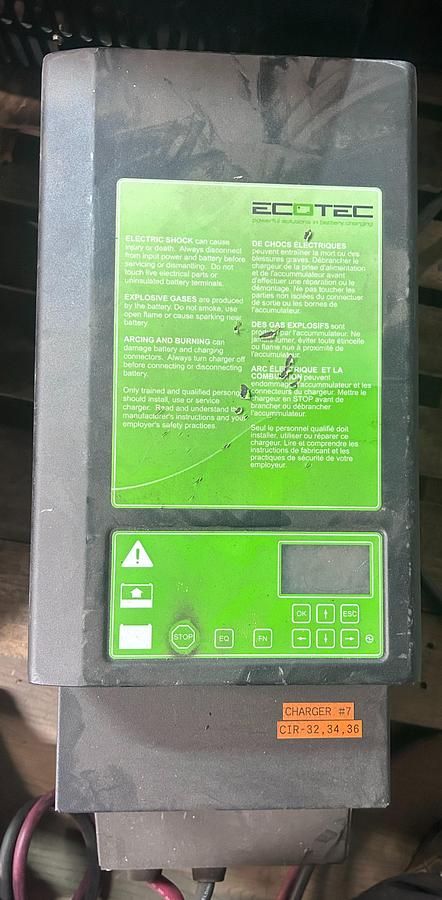

The ECOTEC ACCESS 16/36 is a high‑performance 36V industrial forklift battery charger engineered ...

Discover more36 Volt 260 Amp | ECOTEC ACCESS 16/36 | Industrial Forklift Battery Charger | 480V 3‑Phase | Smart Charging | CSA‑Ready

- Part Number

- 36‑1045‑320C

- Voltage Output (V)

- 36V

- Amperage Output (A)

- 260A

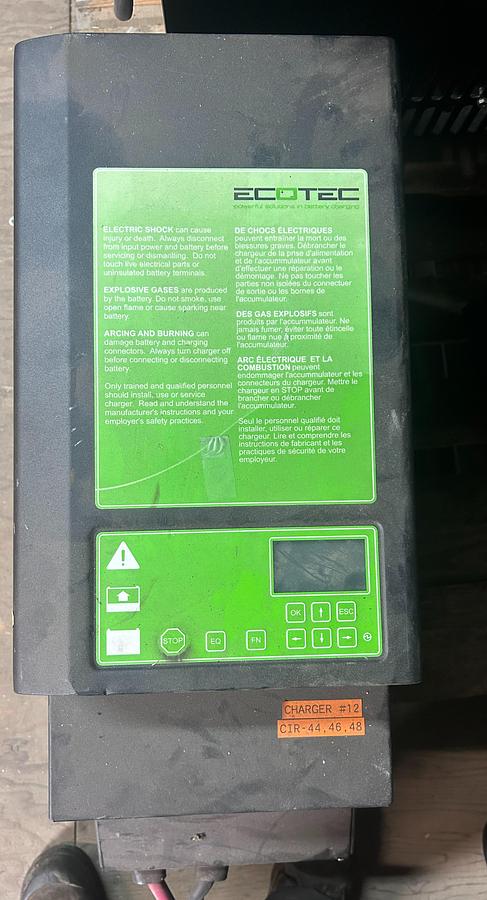

The ECOTEC ACCESS 16/36 is a high‑performance 36V forklift battery charger engineered for industr...

Discover more36 Volt 260 Amp | ECOTEC ACCESS 16/36 | Industrial Forklift Battery Charger | 480V 3‑Phase | Smart Charging | CSA‑Ready

- Part Number

- 36‑1045‑320C

- Voltage Output (V)

- 36V

- Amperage Output (A)

- 260A

The Hawker LIF‑12‑600 is a versatile multi‑voltage industrial forklift battery charger designed t...

Discover more24 Volt 36 Volt 48 Volt | 600 Amp Hour | Hawker LIF‑12‑600 | Multi‑Voltage Forklift Battery Charger | 100A Output | 480V 3‑Phase | CSA‑Ready

- Voltage Output (V)

- 24V • 36V • 48V

- Amperage Output (A)

- 100A / 200A / 300A

- Battery Compatibility

- Lead‑Acid (LA), 12–24 Cells

The Industrial Battery & Charger Inc. 12P10750C3B is a durable 24V forklift battery charger desig...

Discover more24 Volt 750 Amp Hour | Industrial Battery & Charger Inc. 12P10750C3B | 124A Lead‑Acid Forklift Battery Charger | 208/240/480V 3‑Phase | CSA‑Ready

- Voltage Output (V)

- 24V

- Amperage Output (A)

- 124A

- Battery Compatibility

- Lead‑Acid (LA), 12 Cells

This reconditioned Bolzoni Auramo ARC‑84‑1060PSE roll clamp is engineered for high‑capacity roll ...

Discover moreReconditioned Bolzoni Auramo ARC‑84‑1060PSE Roll Clamp | 8,400 lb | 60” Opening | Rotation | Class III/IV Convertible | CSA/MOL Certified

- Capacity

- 8400

- Load Center

- 30"

- Mounting Class

- ITA Class IV

This heavy‑duty paper roll clamp is engineered for high‑capacity roll handling in mills, converti...

Discover moreReconditioned Cascade 90F‑RCS‑254 Paper Roll Clamp | 9,000 lb | 60” Opening | Rotation | Class IV | CSA‑Certified

- Capacity

- 9,000 lbs @ 30" load centre

- Mounting Class

- ITA Class IV

- Rotation

- Yes — rotation equipped (confirmable on inspection)

CSA‑Certified Cascade 90F‑RCP‑321 Paper Roll Clamp – 9,000 lb @ 30" Load Centre | 60" Diameter | ...

Discover moreReconditioned Cascade 90F‑RCP‑321 Paper Roll Clamp | 9,000 lb | 60” Diameter | Class IV | CSA‑Ready

- Capacity

- 9,000 lbs @ 30" load centre

- Mounting Class

- ITA Class IV

- Rotation

- yes — rotation equipped

This refurbished Cascade 25G‑FDS‑1251 double pallet handler is engineered for high‑throughput pal...

Discover moreRefurbished Cascade 25G‑FDS‑1251 Double Pallet Handler | 5,600 lb | Class III | 42” Forks | CSA‑Ready | Multi‑Pallet Handling

- Capacity

- 5500 LBS.

- * Fork Length

- 42"

- Mounting Class

- ITA Class III

CSA‑ready Cascade paper roll clamp, model R90F‑RCF‑02C, engineered for high‑capacity roll handlin...

Discover more2019 Cascade R90F‑RCF‑02C Paper Roll Clamp | 9,000 lb | 10–60” Opening | Class IV | CSA‑Ready

- Capacity

- 9,000 lbs

- Mounting Class

- ITA Class IV

- Rotation

- Yes — full rotation (confirmable on inspection)

This refurbished Cascade 25D‑CCS‑35AR1 carton clamp is engineered for palletless handling of boxe...

Discover moreRefurbished Cascade 25D‑CCS‑35AR1 Carton Clamp | 2,500 lb | 48” Arms | 21.38–76” Opening | Side‑Shift | Class II | CSA‑Ready

- Capacity

- 2500

- Clamp Force

- 138-159 psi

- Arm Length

- 48"

This refurbished Bolzoni Auramo KS09Z6A box clamp delivers reliable, pallet‑free handling for app...

Discover moreRefurbished Bolzoni Auramo KS09Z6A Box Clamp | 48x48 Rubber Pads | Class II | 1,984 lb Capacity | Side Shift | CSA‑Ready

- Capacity

- 1984 LBS.

- Mounting / Class

- Class II

- Pad Size

- 48" x 48"

This reconditioned Cascade PHG45‑A00 push/pull attachment is engineered for pallet‑free handling ...

Discover moreReconditioned Cascade PHG45‑A00 Push/Pull | 4,500 lb | Class II | Platens Included | CSA‑Certified | Slip‑Sheet Handling

- Capacity

- 4500 Lbs.

- Carriage Class

- Class II

- Platens

- Yes

This reconditioned Cascade 25D‑CCS‑35AR1 carton clamp is engineered for pallet‑free handling of b...

Discover moreReconditioned Cascade 25D‑CCS‑35AR1 Carton Clamp | 48” Arms | Class II | New Rubber Pads | CSA‑Certified

- Attachment Type

- Carton Clamp

- Arm Dimensions

- 48” × 48”

- Mounting Class

- Class II

This refurbished Cascade 25G‑FDS‑1005 double pallet handler is engineered for high‑throughput pal...

Discover moreRefurbished Cascade 25G‑FDS‑1005 Double Pallet Handler | 5,500 lb | Class III | 42” Forks | CSA‑Ready

- Capacity

- 5500 LBS.

- * Fork Length

- 42"

- Mounting Class

- ITA Class III

These 2008 Premier Lift heavy‑duty shaft‑mount forks are engineered for high‑capacity material ha...

Discover more2008 Premier Lift Shaft‑Mount Forks | 15,000 lb Capacity | Shaft‑Mount (Pin‑Type) | CSA‑Certified | Heavy‑Duty Industrial Forks

- Class

- 4

- Capacity

- 15000

- Mounting Type

- Shaft‑Mount

This 2016 Cascade R90F‑RGF‑020 is a fully reconditioned paper roll clamp engineered for pallet‑fr...

Discover more2016 Cascade R90F‑RGF‑020 Paper Roll Clamp | CSA‑Certified | 9,000 lb | 60” Diameter | Class IV

- Attachment Type

- Paper Roll Clamp

- Diameter Range

- 60”

- Carriage Class

- Class IV